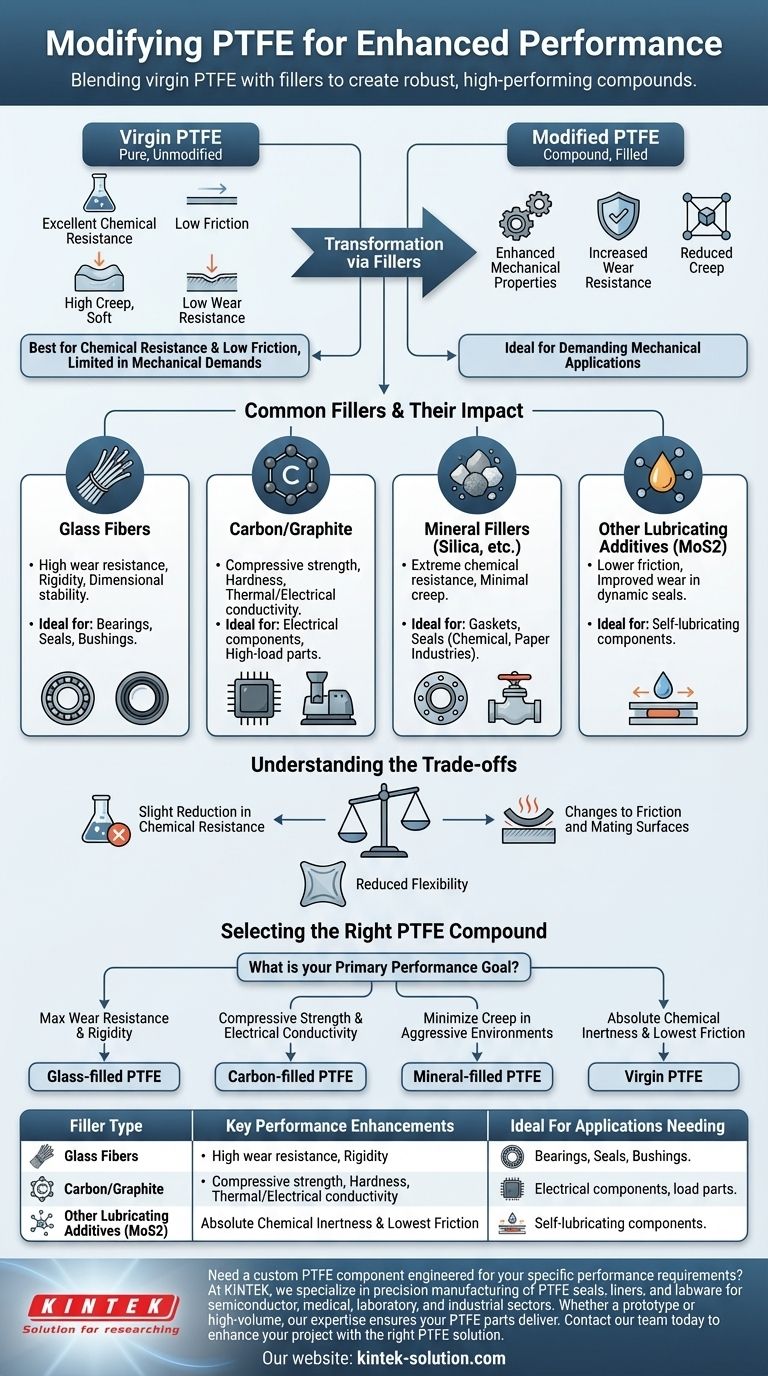

To enhance the performance of Polytetrafluoroethylene (PTFE), it is most commonly modified by blending it with various inorganic and organic filler materials. Additives like glass fibers, carbon, and graphite are integrated into the PTFE matrix to create compounds with significantly improved mechanical properties. These enhancements primarily target wear resistance, compressive strength, and resistance to deformation under load.

While virgin PTFE is unparalleled in chemical resistance and low friction, its inherent softness limits its use in mechanically demanding applications. Modifying PTFE with fillers is a strategic engineering choice to gain crucial strength and durability, transforming it into a robust material for a wider range of uses.

The Purpose of Modifying PTFE

To understand why PTFE is modified, we must first appreciate the distinct properties of its pure, or "virgin," state. This provides the context for the specific problems that fillers are meant to solve.

The Strengths of Virgin PTFE

Virgin PTFE is a remarkable polymer known for a unique combination of characteristics. It offers outstanding resistance to nearly all chemicals, an extremely low coefficient of friction, excellent performance at elevated temperatures, and great weatherability.

Where Virgin PTFE Falls Short

Despite its strengths, the softness and poor flow characteristics of virgin PTFE create significant limitations. It is susceptible to creep (the tendency to slowly deform under a constant load) and has low resistance to wear and abrasion. This makes it unsuitable for applications involving high pressure or significant friction.

The Role of Fillers

Fillers are added to create a composite material, often called a PTFE compound. These particles form a reinforcing matrix within the softer PTFE, fundamentally improving its mechanical properties. They increase hardness, boost wear resistance, and drastically reduce creep.

Common Fillers and Their Impact

The choice of filler directly dictates the performance enhancements of the final PTFE compound. Each material imparts a unique set of characteristics tailored for specific applications.

Glass Fibers

Glass is one of the most common fillers used in PTFE. Compounds with 15% or 25% glass fiber are widely available and offer a dramatic improvement in wear resistance and rigidity. This modification significantly reduces deformation under load and enhances dimensional stability.

Carbon and Graphite

Adding carbon or graphite (or a combination of both) to PTFE enhances its compressive strength, hardness, and wear resistance. These fillers are particularly useful for applications requiring improved thermal conductivity and, in the case of carbon, electrical conductivity.

Mineral Fillers (Silica, Barium Sulfate)

For applications demanding extreme chemical resistance coupled with minimal creep, PTFE is modified with mineral fillers like silica, barium sulfate, or glass microspheres. These compounds are often used for gasketing and sealing against steel, glass, or plastic flanges, especially in the chemical and paper industries.

Other Lubricating Additives

In some cases, materials like molybdenum disulfide are added to PTFE. This additive primarily acts as a dry lubricant, further reducing the coefficient of friction and improving wear properties, particularly in dynamic sealing applications.

Understanding the Trade-offs

Modifying PTFE is not a matter of simple improvement; it is an engineering trade-off. Enhancing one property can subtly alter others, and understanding this balance is critical for proper material selection.

Impact on Chemical Resistance

While filled PTFE compounds maintain excellent chemical resistance, they are not as universally inert as virgin PTFE. The filler material itself may be susceptible to attack by certain aggressive chemicals that pure PTFE would otherwise resist.

Changes to Friction and Mating Surfaces

Adding abrasive fillers like glass fibers can slightly increase the coefficient of friction compared to virgin PTFE. More importantly, these harder compounds can cause wear on softer mating surfaces like aluminum or other plastics. This must be considered in the overall system design.

Reduced Flexibility

The addition of fillers increases the rigidity and hardness of PTFE. This reduces the material's natural softness and formability, which can be a drawback in applications that require the material to conform to irregular surfaces.

Selecting the Right PTFE Compound

The ideal modified PTFE depends entirely on the specific demands of your application. Choosing the correct compound requires a clear understanding of your primary performance goal.

- If your primary focus is maximum wear resistance and rigidity: Glass-filled PTFE is the standard choice, but be mindful of its effect on softer mating surfaces.

- If your primary focus is compressive strength and electrical conductivity: A carbon-filled PTFE compound will likely provide the best performance.

- If your primary focus is minimizing creep under load in chemically aggressive environments: Look for compounds using mineral fillers like silica or barium sulfate.

- If your primary focus is absolute chemical inertness and the lowest possible friction: Virgin, unmodified PTFE remains the correct solution.

By understanding these filler systems, you can specify a PTFE material precisely engineered to overcome its natural limitations and succeed in your application.

Summary Table:

| Filler Type | Key Performance Enhancements | Ideal For Applications Needing |

|---|---|---|

| Glass Fibers | High wear resistance, rigidity, dimensional stability | Bearings, seals, bushings |

| Carbon/Graphite | Compressive strength, hardness, thermal/electrical conductivity | Electrical components, high-load parts |

| Mineral Fillers (e.g., Silica) | Extreme chemical resistance, minimal creep | Chemical processing gaskets, seals |

| Other (e.g., Molybdenum Disulfide) | Lower friction, improved wear in dynamic seals | Self-lubricating components |

Need a custom PTFE component engineered for your specific performance requirements? At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise in custom fabrication ensures your PTFE parts deliver the exact mechanical properties, chemical resistance, and durability your application demands. Contact our team today to discuss how we can enhance your project with the right PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications