Polytetrafluoroethylene (PTFE) is a cornerstone material in modern electronics due to its exceptional combination of electrical insulation properties. Its value stems directly from its high electrical resistance, high dielectric strength, and a very low dielectric constant, which together ensure reliable and safe performance in components ranging from simple wire insulation to complex semiconductors.

The true value of PTFE isn't just that it's a good insulator; it's that its unique molecular structure provides a suite of electrical characteristics that guarantee signal integrity and operational safety, especially in high-frequency and high-temperature environments.

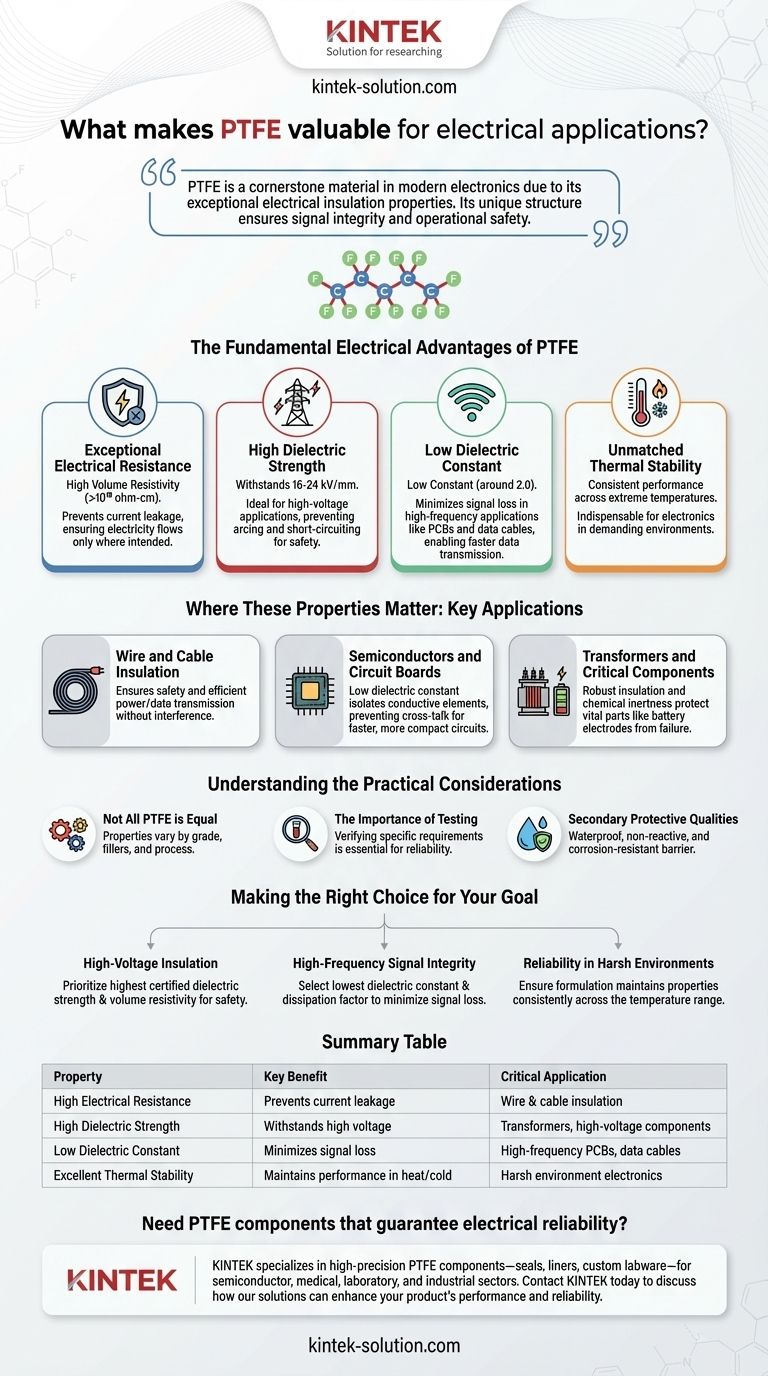

The Fundamental Electrical Advantages of PTFE

PTFE's effectiveness in electrical applications is not based on a single trait, but on the interplay of several fundamental properties that originate from its molecular makeup.

Exceptional Electrical Resistance

PTFE is one of the best electrical insulators known. It possesses an extremely high volume resistivity (greater than 10¹⁸ ohm-cm), which means it strongly resists the flow of electrical current.

This property is critical for preventing current leakage between conductors, ensuring that electricity flows only where it is intended.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand high voltage before it breaks down and begins to conduct electricity.

PTFE can withstand 16-24 kV/mm, making it an ideal insulator for high-voltage applications. This prevents arcing or short-circuiting, which is crucial for safety and component longevity.

Low Dielectric Constant

Thanks to its highly symmetric molecular structure, PTFE has a very low dielectric constant (around 2.0). A low dielectric constant means the material stores very little electrical energy when subjected to an electric field.

This is paramount in high-frequency applications, such as data cables and printed circuit boards (PCBs), as it minimizes signal loss and distortion, allowing for faster and cleaner data transmission.

Unmatched Thermal Stability

A key advantage of PTFE is its ability to maintain these excellent electrical properties across a vast range of temperatures.

Where other insulators might fail or degrade in extreme heat or cold, PTFE performs consistently, making it indispensable for electronics that operate in demanding environments.

Where These Properties Matter: Key Applications

The theoretical advantages of PTFE translate directly into tangible benefits across several critical electrical and electronic fields.

Wire and Cable Insulation

The combination of high electrical resistance and high dielectric strength makes PTFE a primary choice for insulating wires and cables. It ensures both safety and the efficient transmission of power or data without interference.

Semiconductors and Circuit Boards

In advanced electronics, the low dielectric constant of PTFE is its most valuable asset. It is used in manufacturing semiconductors and PCBs to isolate conductive elements, preventing signal cross-talk and enabling the design of faster, more compact, and more efficient circuits.

Transformers and Critical Components

Components like transformers, battery electrodes, and battery separators rely on PTFE for its robust insulation and chemical inertness. Its ability to resist electrical current and corrosion protects these vital parts from failure.

Understanding the Practical Considerations

While PTFE's properties are outstanding, achieving optimal performance requires careful consideration of the material's specifics.

Not All PTFE is Created Equal

The electrical properties of a PTFE component can vary based on its grade, the type and concentration of any fillers, and the manufacturing process used. For example, a molded sheet may have different characteristics than an extruded tube.

The Importance of Testing

Because of these potential variations, testing is not just a recommendation; it is a necessity. Verifying that the specific PTFE material meets the precise electrical requirements of your application is essential for ensuring the final product's performance and reliability.

Its Secondary Protective Qualities

Beyond its electrical prowess, PTFE is also waterproof, non-reactive, and corrosion-resistant. These characteristics provide an additional protective barrier, shielding sensitive electronic components from environmental damage.

Making the Right Choice for Your Goal

To leverage PTFE effectively, align your material selection with the most critical demand of your application.

- If your primary focus is high-voltage insulation: Prioritize PTFE with the highest certified dielectric strength and volume resistivity to ensure safety and prevent electrical breakdown.

- If your primary focus is high-frequency signal integrity: Select a PTFE grade with the lowest possible dielectric constant and dissipation factor to minimize signal loss in data cables or circuit boards.

- If your primary focus is reliability in harsh environments: Ensure the chosen PTFE formulation is proven to maintain its critical electrical properties consistently across your entire operational temperature range.

Ultimately, understanding these core electrical characteristics allows you to use PTFE not just as an insulator, but as a strategic component for enhancing electronic performance and reliability.

Summary Table:

| Property | Key Benefit | Critical Application |

|---|---|---|

| High Electrical Resistance | Prevents current leakage | Wire & cable insulation |

| High Dielectric Strength | Withstands high voltage | Transformers, high-voltage components |

| Low Dielectric Constant | Minimizes signal loss | High-frequency PCBs, data cables |

| Excellent Thermal Stability | Maintains performance in extreme heat/cold | Harsh environment electronics |

Need PTFE components that guarantee electrical reliability?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the exact electrical specifications required for safety and performance, from prototype to high-volume production.

Contact KINTEK today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments