In short, PTFE spring-energized seals are suitable for oil and gas applications because their core material, Polytetrafluoroethylene (PTFE), offers near-universal chemical resistance, an extremely low coefficient of friction, and a vast operational temperature range. The internal spring provides a constant mechanical force, ensuring these properties translate into a reliable, long-term seal even under the extreme pressures and dynamic conditions common in drilling, production, and processing.

The success of these seals in the oil and gas sector stems from a critical synergy: the exceptional inertness and durability of the PTFE jacket combined with the persistent mechanical force of the energizing spring. This combination creates a seal that remains effective when elastomers would degrade or fail.

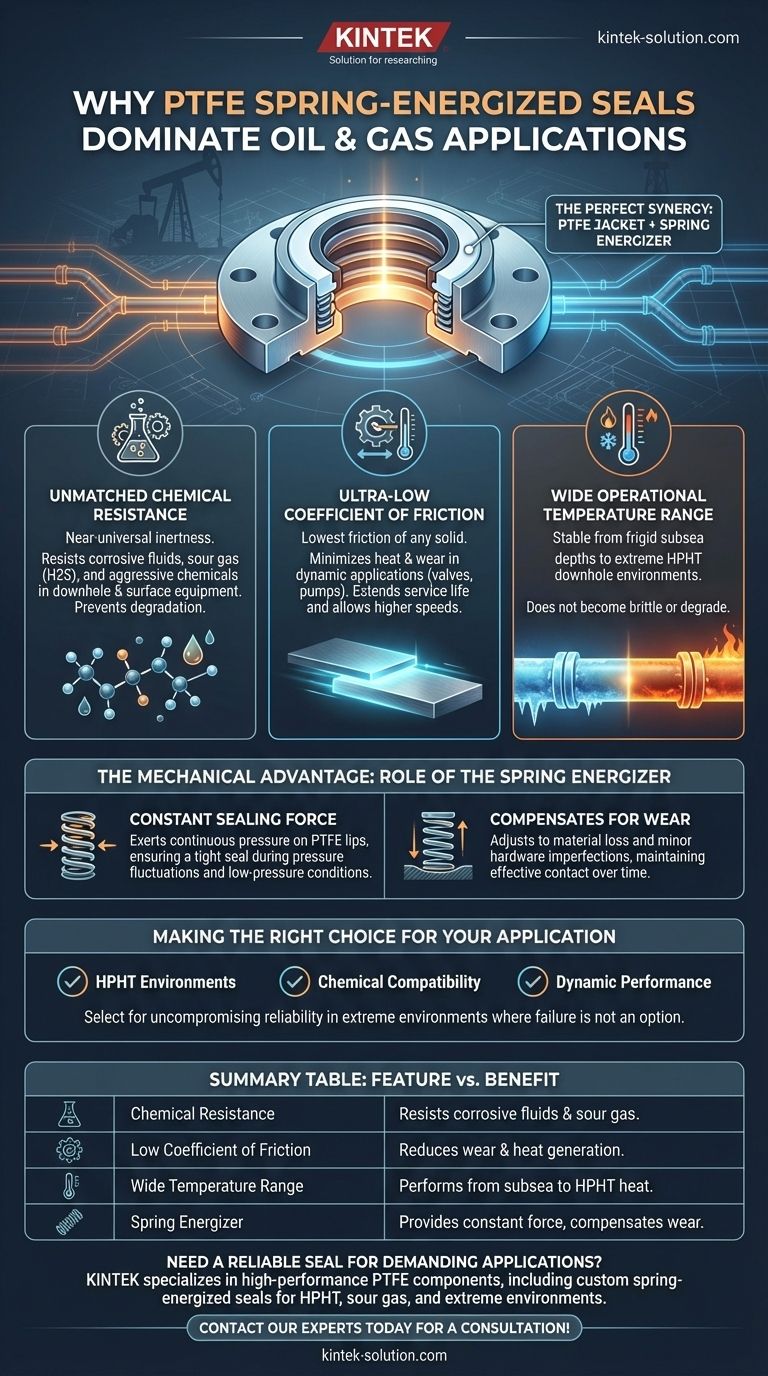

The Core Material Advantage: Why PTFE Excels

The foundation of a spring-energized seal's performance is its PTFE jacket. This material possesses a unique combination of properties that make it ideal for the harsh realities of the oil and gas industry.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known, often called the "king of plastic." It is virtually immune to the corrosive drilling fluids, sour gas (H2S), and aggressive chemicals encountered in downhole tools and surface equipment.

This universal resistance ensures the seal's integrity is not compromised over time, preventing chemical degradation that would cause conventional seals to swell, crack, or dissolve.

Extremely Low Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid. In practical terms, this means it is incredibly slick, which is a major advantage in dynamic applications like valves, pumps, and swivels.

This ultra-low friction minimizes heat generation and wear during operation, extending the service life of both the seal and the mating hardware. It allows for higher surface speeds than are possible with traditional elastomeric seals.

Wide Operational Temperature Range

Oil and gas operations span from the frigid depths of subsea equipment to the extreme heat of High-Pressure, High-Temperature (HPHT) downhole environments.

PTFE maintains its stability and sealing properties across this enormous temperature spectrum. It doesn't become brittle at low temperatures or degrade at the high temperatures that would destroy rubber-based seals.

The Mechanical Advantage: The Role of the Spring Energizer

While the PTFE jacket provides the material resistance, the spring is what gives the seal its mechanical life and responsiveness. PTFE is a relatively rigid plastic and lacks the "memory" or elasticity of rubber.

Ensuring a Constant Sealing Force

The spring exerts a continuous, uniform force against the PTFE lips, pushing them against the sealing surfaces. This is critical for maintaining a tight seal during pressure fluctuations or at very low pressures where system media can't fully activate the seal.

Compensating for Wear and Imperfections

Over the seal's life, minor wear will occur on the PTFE jacket. The spring constantly adjusts, pushing the sealing lip outward to compensate for this material loss and maintain effective contact.

This adaptability also allows the seal to accommodate minor hardware misalignments or surface imperfections, ensuring reliable performance in real-world conditions.

Understanding the Trade-offs

While highly effective, it's important to recognize the specific context where these seals excel and their inherent limitations.

Limited Elasticity Compared to Elastomers

By design, PTFE is not a true elastomer. It does not have the "bounce back" of a rubber O-ring. This is why the spring is essential; without it, a PTFE ring would have poor sealing capability, especially in dynamic situations.

Higher Potential for Extrusion

Under extreme pressure, the relatively soft PTFE material can be forced into the clearance gap between metal components. This can be mitigated by using specialized filled-PTFE grades for higher hardness or incorporating anti-extrusion backup rings into the design.

Installation Sensitivity

The relative stiffness of PTFE seals compared to elastomers means they require more care during installation. Improper handling can scratch or nick the sealing lip, compromising its performance from the start.

Making the Right Choice for Your Application

Selecting the right seal requires matching its strengths to your primary operational challenge.

- If your primary focus is HPHT environments: The exceptional thermal stability of the PTFE jacket makes it the clear choice for downhole tools and wellhead equipment where other materials would fail.

- If your primary focus is chemical compatibility: For applications involving sour gas, aggressive inhibitors, or complex drilling fluids, PTFE's near-universal inertness provides unmatched reliability.

- If your primary focus is dynamic performance: In high-speed pumps or frequently actuated valves, the low-friction and low-wear properties of a PTFE seal ensure a longer operational life and reduced maintenance.

Ultimately, selecting a PTFE spring-energized seal is a decision for uncompromising reliability in environments where failure is not an option.

Summary Table:

| Feature | Benefit in Oil & Gas |

|---|---|

| Chemical Resistance | Resists corrosive fluids, sour gas (H2S), and aggressive chemicals. |

| Low Coefficient of Friction | Reduces wear and heat generation in dynamic applications like valves and pumps. |

| Wide Temperature Range | Maintains performance from subsea cold to extreme HPHT downhole heat. |

| Spring Energizer | Provides constant sealing force, compensating for wear and pressure fluctuations. |

Need a reliable seal for your most demanding oil and gas applications?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom spring-energized seals. Our precision production ensures your seals deliver unmatched reliability in HPHT, sour gas, and other extreme environments.

We offer custom fabrication from prototypes to high-volume orders, tailored to the specific needs of the semiconductor, medical, laboratory, and industrial sectors.

Let's discuss how our PTFE seals can solve your critical sealing challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications