In short, PTFE rotary shaft lip seals are suitable for aerospace because they operate reliably under extreme conditions where traditional seals fail. Their unique material properties allow them to withstand the intense temperatures, high rotational speeds, and aggressive chemicals found in critical systems like aircraft engines, landing gear, and fuel pumps, ensuring mission safety and operational efficiency.

The core challenge in aerospace engineering is sourcing components that offer uncompromising reliability in a zero-failure environment. PTFE seals meet this challenge by providing a unique combination of thermal stability, low-friction operation, and chemical inertness that traditional elastomeric seals simply cannot match.

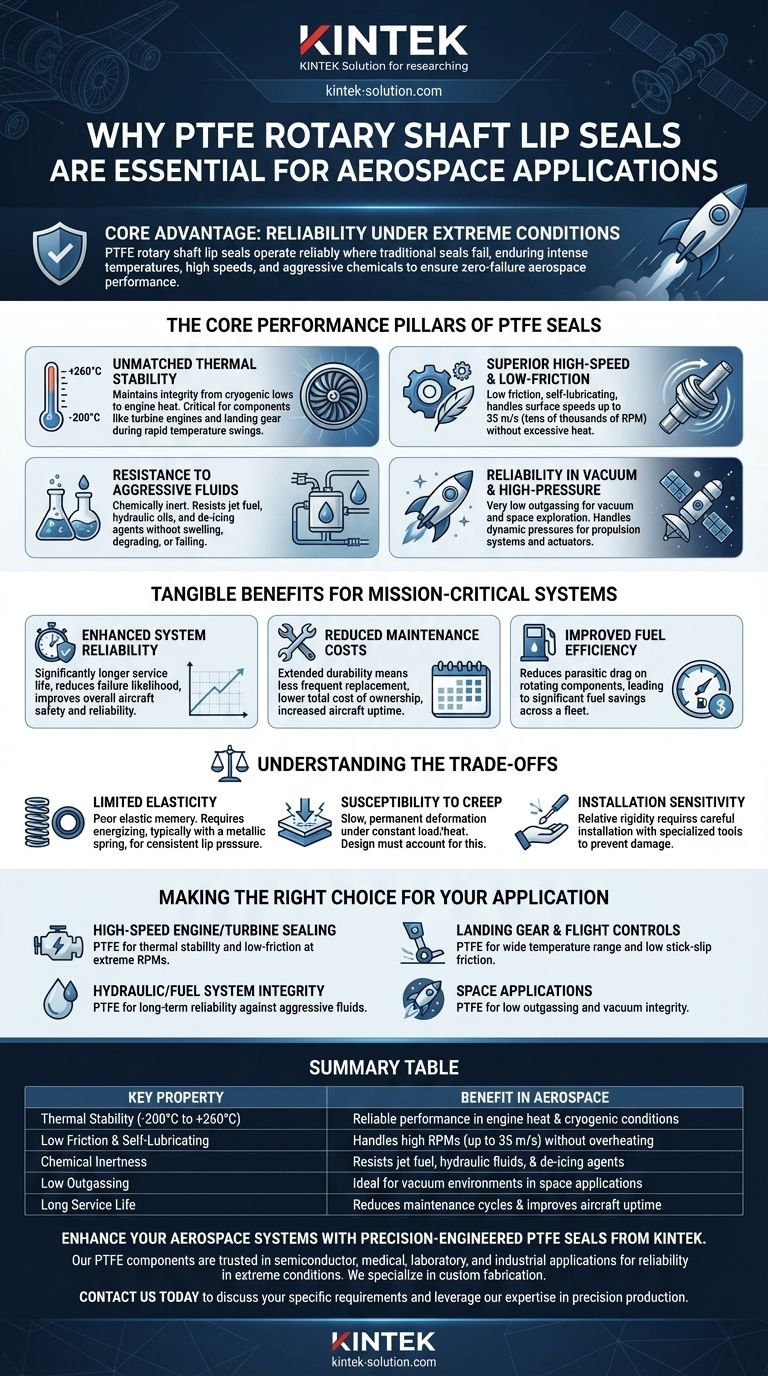

The Core Performance Pillars of PTFE Seals in Aerospace

Aerospace applications subject components to some of the most demanding operational conditions imaginable. The suitability of PTFE (Polytetrafluoroethylene) stems from its inherent ability to not just survive, but excel in this environment.

Unmatched Thermal Stability

PTFE seals maintain their integrity across an exceptionally wide temperature range, from cryogenic lows to the extreme heat of an engine.

This is critical for components like turbine engines or landing gear, which experience drastic and rapid temperature swings during a typical flight envelope. Where other materials would become brittle or degrade, PTFE remains stable.

Superior High-Speed and Low-Friction Operation

Aerospace systems often involve extremely high rotational speeds, such as in turbines, generators, and fuel pumps, which can reach tens of thousands of RPM.

PTFE has an exceptionally low coefficient of friction and is self-lubricating. This means it can handle shaft surface speeds up to 35 m/s without generating excessive heat, which is a primary cause of premature seal failure in high-speed applications.

Resistance to Aggressive Aerospace Fluids

Aerospace systems rely on a variety of aggressive fluids, including jet fuel, hydraulic oils, and de-icing agents.

PTFE is almost universally chemically inert. This property ensures the seal will not swell, degrade, or fail when in constant contact with these corrosive substances, guaranteeing the long-term integrity of fuel and hydraulic systems.

Reliability in Vacuum and High-Pressure Environments

For space exploration and high-altitude flight, components must perform in a vacuum. PTFE exhibits very low outgassing, meaning it does not release trapped gasses that could contaminate sensitive instruments or compromise the vacuum.

This, combined with its ability to handle dynamic pressures, makes it an ideal choice for rocket propulsion systems, actuators, and other critical flight components.

The Tangible Benefits for Mission-Critical Systems

The material properties of PTFE translate directly into measurable improvements in reliability, cost, and performance.

Enhanced System Reliability

The combination of thermal, chemical, and mechanical resilience means PTFE seals have a significantly longer service life than many alternatives.

This reduces the likelihood of seal failure, a critical factor in systems where failure could have catastrophic consequences. It directly leads to improved overall aircraft reliability and safety.

Reduced Maintenance and Operational Costs

The extended service life and durability of PTFE seals mean less frequent inspection and replacement cycles.

This reduction in required maintenance lowers the total cost of ownership and increases aircraft availability and uptime.

Improved Fuel Efficiency

The low-friction, self-lubricating nature of PTFE seals reduces the parasitic drag on rotating components within an engine or auxiliary power unit.

This small efficiency gain, when multiplied across an entire fleet, can lead to significant fuel savings. Some estimates suggest improvements that could save a single airline up to $1.7 million per year in operating costs.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Its unique properties come with design considerations that are crucial for successful implementation.

Limited Elasticity

Unlike rubber-based elastomers, PTFE has very poor elastic memory. It does not spring back to its original shape easily after being deformed.

Because of this, PTFE seals are almost always energized, typically with a metallic spring, to ensure consistent lip pressure against the shaft.

Susceptibility to Creep

Under a constant load and high temperature, PTFE can be susceptible to "creep," a slow, permanent deformation.

Seal and hardware design must account for this behavior to ensure a reliable sealing interface is maintained throughout the component's life.

Installation Sensitivity

The relative rigidity of PTFE compared to elastomers means that installation requires greater care. Specialized tools and procedures are often necessary to prevent scratching or damaging the seal lip, which could compromise its performance.

Making the Right Choice for Your Application

Selecting the right seal requires matching its capabilities to the specific demands of the system.

- If your primary focus is high-speed engine or turbine sealing: PTFE is the definitive choice due to its thermal stability and low-friction performance at extreme RPMs.

- If your primary focus is hydraulic or fuel system integrity: PTFE's chemical inertness ensures long-term reliability against aggressive fluids.

- If your primary focus is reliability in landing gear or flight controls: The combination of a wide temperature range and low stick-slip friction makes PTFE ideal for these critical dynamic systems.

- If your primary focus is components for space applications: PTFE's low outgassing properties are non-negotiable for maintaining vacuum integrity and protecting sensitive optics.

By understanding these core material properties, you can confidently specify PTFE seals to enhance the safety, reliability, and efficiency of your aerospace designs.

Summary Table:

| Key Property | Benefit in Aerospace |

|---|---|

| Thermal Stability (-200°C to +260°C) | Reliable performance in engine heat and cryogenic conditions |

| Low Friction & Self-Lubricating | Handles high RPMs (up to 35 m/s) without overheating |

| Chemical Inertness | Resists jet fuel, hydraulic fluids, and de-icing agents |

| Low Outgassing | Ideal for vacuum environments in space applications |

| Long Service Life | Reduces maintenance cycles and improves aircraft uptime |

Enhance your aerospace systems with precision-engineered PTFE seals from KINTEK.

Our PTFE components (seals, liners, labware) are trusted in semiconductor, medical, laboratory, and industrial applications for their reliability in extreme conditions. We specialize in custom fabrication from prototypes to high-volume orders, ensuring your aerospace designs meet zero-failure standards.

Contact us today to discuss your specific requirements and leverage our expertise in precision production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments