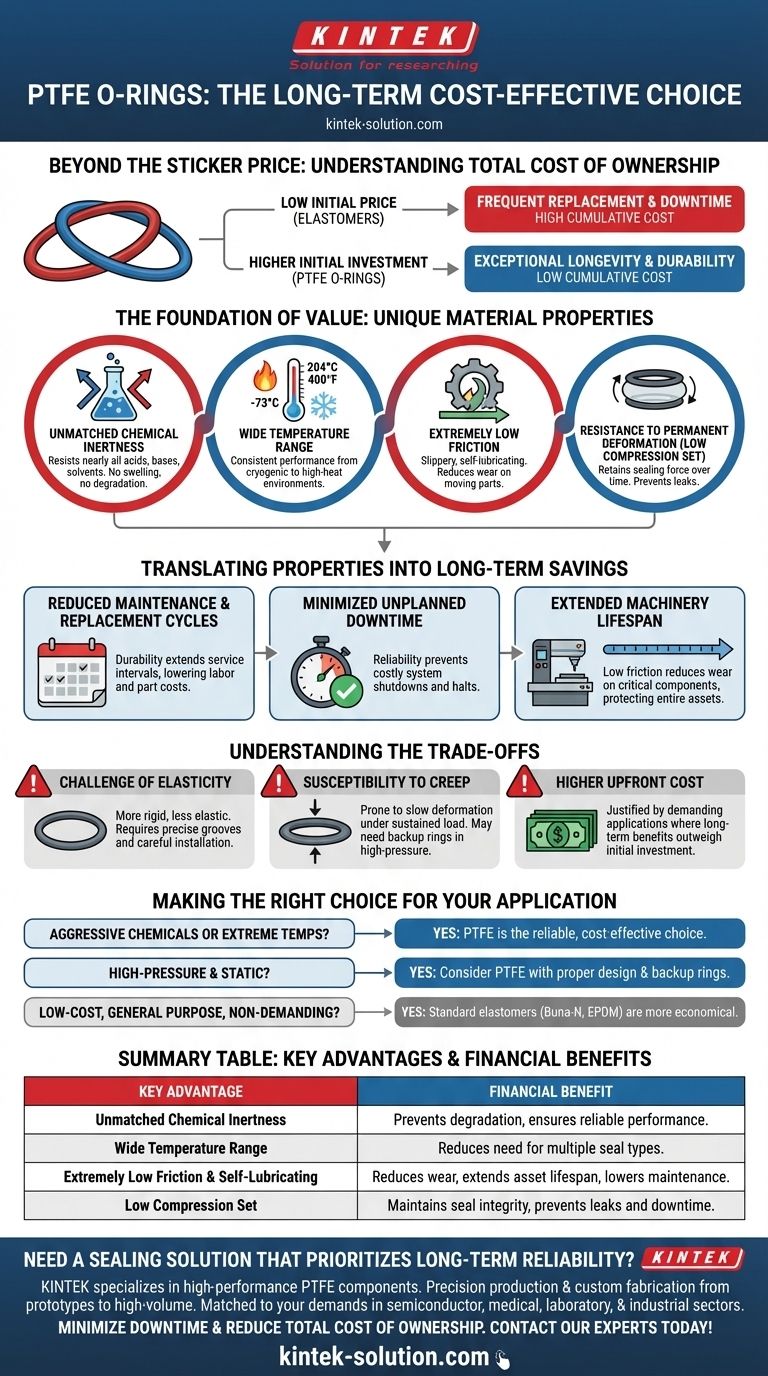

At first glance, Polytetrafluoroethylene (PTFE) O-rings may not have the lowest initial purchase price compared to common elastomers. Their cost-effectiveness is not derived from their sticker price, but from their exceptional longevity and durability in demanding environments, which dramatically reduces the total cost of ownership by minimizing equipment downtime and the need for frequent replacements.

The true cost of a sealing component is not its upfront price, but the cost of its potential failure. PTFE's value lies in its ability to prevent costly system failures and maintenance cycles in applications where other materials would quickly degrade.

The Foundation of PTFE's Value: Material Properties

The long-term economic benefit of PTFE O-rings is a direct result of their unique and powerful material characteristics. These properties allow them to survive in conditions that would destroy conventional seals.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents. This chemical inertness means the O-ring will not swell, degrade, or break down when exposed to harsh fluids, ensuring a stable and reliable seal.

Wide Operational Temperature Range

These O-rings perform consistently across an exceptionally broad temperature spectrum, typically from -73°C to 204°C (-100°F to 400°F). This makes them suitable for everything from cryogenic applications to high-temperature engine and processing environments.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a slippery, non-stick surface. This self-lubricating quality reduces wear on both the seal and the machinery's moving parts, which is critical in dynamic or rotary applications.

Resistance to Permanent Deformation

PTFE exhibits a very low compression set. This technical term means that when compressed to form a seal, it resists being permanently flattened. It retains its original shape and sealing force over long periods, preventing leaks that develop as other materials age and deform.

Translating Properties into Long-Term Savings

Superior material properties are only valuable if they translate into tangible financial benefits. For PTFE, the connection is direct and significant.

Reduced Maintenance and Replacement Cycles

Because PTFE O-rings are highly resistant to chemical attack, abrasion, and wear, they simply last longer. This durability extends the time between scheduled maintenance, reducing labor costs and the expense of replacement parts over the equipment's lifespan.

Minimized Unplanned Downtime

A failed seal often leads to a complete system shutdown, halting operations and causing major financial losses. The reliability of PTFE in harsh conditions provides a powerful insurance policy against such unplanned and costly downtime.

Extended Machinery Lifespan

In dynamic applications, the low-friction nature of PTFE reduces wear and tear on shafts and bores. By minimizing damage to these critical and expensive machine components, the O-ring contributes to the overall longevity of the entire asset.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Acknowledging its specific limitations is key to using it correctly and avoiding misapplication.

The Challenge of Elasticity

Compared to rubber elastomers, PTFE is a relatively rigid material. It has very little elasticity, which can make installation more challenging. It requires precisely machined grooves and careful handling to ensure a proper fit without damaging the seal.

Susceptibility to Creep

Under a constant, sustained load (especially at elevated temperatures), PTFE can be prone to creep, or slow deformation over time. In high-pressure applications, this must be managed with proper engineering, often by incorporating backup rings to support the O-ring and prevent extrusion.

Higher Upfront Cost

The initial purchase price of a PTFE O-ring is typically higher than that of a standard nitrile (Buna-N) or Viton O-ring. The decision to use PTFE must be justified by a demanding application where the long-term benefits of its durability will outweigh this initial investment.

Making the Right Choice for Your Application

Selecting the most cost-effective sealing solution requires matching the material to the operational demands.

- If your primary focus is aggressive chemical exposure or extreme temperatures: PTFE is often the most reliable and ultimately cost-effective choice, as lesser materials will fail quickly.

- If your application is high-pressure and static: Consider PTFE, but ensure proper groove design and the use of backup rings to mitigate the risk of creep.

- If you need a low-cost, general-purpose seal for a non-demanding environment: A standard elastomer like Buna-N or EPDM is likely the more economical and appropriate choice.

Ultimately, choosing the right seal requires looking beyond the price tag to the total cost of reliability.

Summary Table:

| Key Advantage | Financial Benefit |

|---|---|

| Unmatched Chemical Inertness | Prevents degradation from harsh fluids, ensuring reliable performance. |

| Wide Temperature Range (-73°C to 204°C) | Suitable for cryogenic to high-heat applications, reducing the need for multiple seal types. |

| Extremely Low Friction & Self-Lubricating | Reduces wear on machinery, extending asset lifespan and lowering maintenance costs. |

| Low Compression Set | Maintains seal integrity over time, preventing leaks and associated downtime. |

Need a sealing solution that prioritizes long-term reliability over short-term cost?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including O-rings, seals, liners, and custom labware. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal perfectly matched to your application's demands in the semiconductor, medical, laboratory, and industrial sectors.

Let us help you minimize downtime and reduce your total cost of ownership. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability