At its core, PTFE is suitable for cryogenic applications because it maintains the essential physical properties required for a reliable seal—flexibility and strength—at extremely low temperatures where other materials become brittle and fail. While many polymers turn glass-like and crack, PTFE remains tough and pliable enough to seal effectively in systems operating as low as -200°C (-328°F).

The true value of PTFE in cryogenics is not just its temperature rating, but its unique combination of properties. It remains chemically inert, mechanically strong, and flexible enough to compensate for thermal contraction, ensuring a dependable seal for volatile liquefied gases.

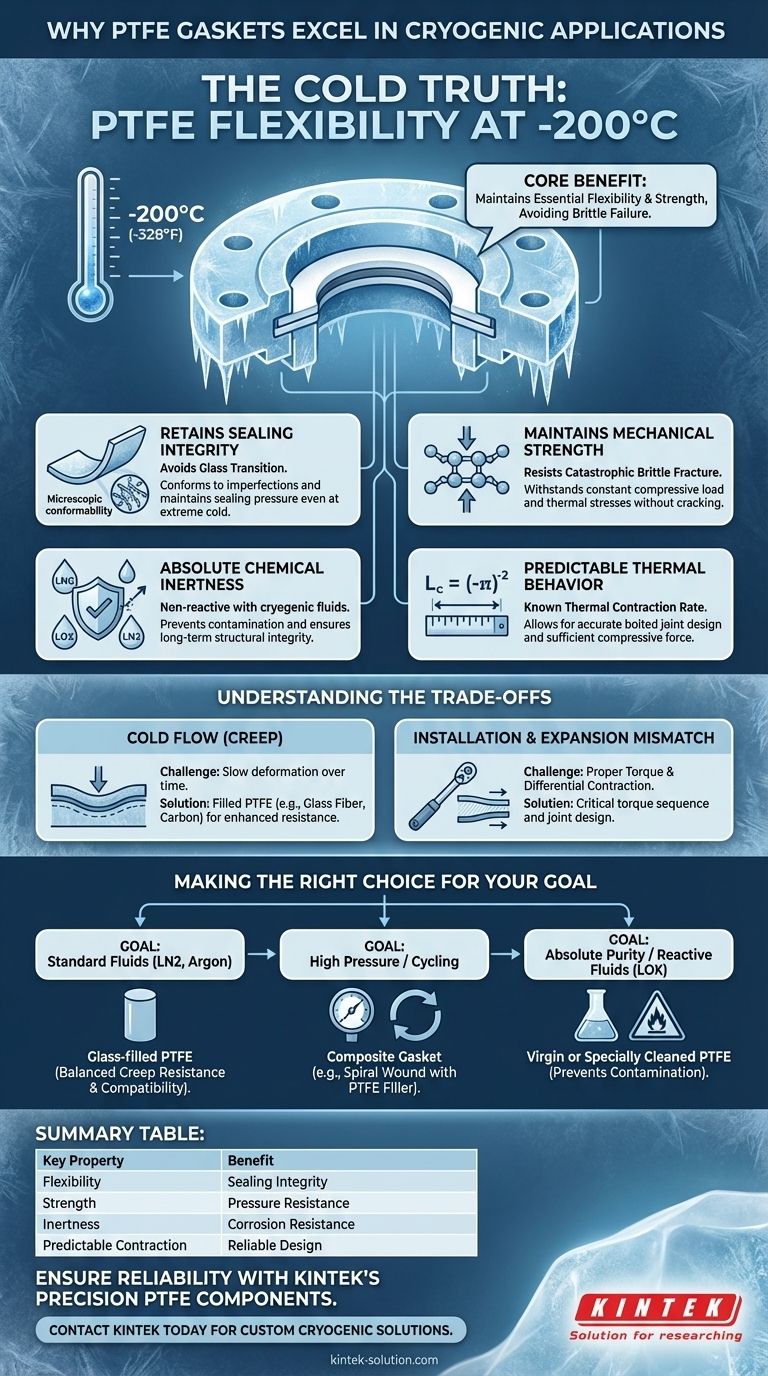

The Science Behind PTFE's Cryogenic Performance

To trust a material in a critical cryogenic system, you must understand why it works. PTFE’s performance is not based on a single trait but on the interplay of several key characteristics that persist even under extreme cold.

Retaining Sealing Integrity

Most materials, especially common elastomers and plastics, undergo a "glass transition" at low temperatures. They lose their rubbery properties and become hard and brittle, making them incapable of sealing.

PTFE, by contrast, retains a significant degree of toughness and flexibility far below the freezing point of most substances. This allows the gasket to conform to the microscopic imperfections of flange surfaces and maintain sealing pressure, even as the entire assembly cools and contracts.

Maintaining Mechanical Strength

A seal must not only be flexible but also strong enough to withstand system pressure. The molecular structure of PTFE helps it avoid catastrophic brittle fracture at cryogenic temperatures.

This inherent strength, mentioned in reference to PTFE valve components, is critical for gaskets that are under constant compressive load from flange bolts. It ensures the gasket material will not crack or be crushed as thermal stresses are introduced during cooldown.

Absolute Chemical Inertness

Cryogenic fluids, such as liquefied natural gas (LNG), liquid oxygen (LOX), or liquid nitrogen (LN2), can be highly reactive or require extreme purity.

PTFE is one of the most non-reactive materials known. It will not degrade, corrode, or react with the fluid it contains. This chemical inertness is vital for preventing contamination of the process fluid and ensuring the long-term structural integrity of the gasket itself.

Predictable Thermal Behavior

All materials shrink when cooled. The key to a good cryogenic seal is managing this contraction. PTFE has a known and predictable rate of thermal contraction.

Engineers can design bolted flange joints that account for this behavior, ensuring that sufficient compressive force remains on the gasket to maintain a seal even after the entire system has reached its cryogenic operating temperature.

Understanding the Trade-offs

No material is perfect. While PTFE is a top choice for cryogenics, understanding its limitations is essential for proper application and avoiding failure.

The Challenge of Cold Flow (Creep)

Standard, or "virgin," PTFE is a relatively soft material and can be susceptible to cold flow, also known as creep. This is the tendency of the material to slowly deform over time under a constant load.

In a bolted flange, this can lead to a loss of bolt torque and a potential leak path. For this reason, filled PTFE grades (e.g., blended with glass fiber, carbon, or bronze) are often specified for critical cryogenic applications to significantly improve creep resistance.

The Importance of Installation

The potential for creep and thermal contraction makes proper installation paramount.

Applying the correct bolt torque in the correct sequence is even more critical for PTFE in cryogenic service than in standard applications. Over-tightening can accelerate cold flow, while under-tightening can fail to create the initial seal needed to overcome thermal contraction.

Thermal Expansion Mismatch

The metal flanges of the joint (typically stainless steel) and the PTFE gasket will contract at different rates as they cool. The joint's design and the gasket's properties must work together to maintain a seal despite this mismatch. This is why gasket selection and joint design are inseparable in cryogenic systems.

Making the Right Choice for Your Goal

Selecting the correct PTFE gasket involves matching the material variant and design to your specific operational demands.

- If your primary focus is sealing standard cryogenic fluids like LN2 or Argon: A glass-filled PTFE gasket is often the best starting point, offering a good balance of enhanced creep resistance and chemical compatibility.

- If your primary focus is handling high pressures or pressure cycling: Consider a composite gasket design, such as a spiral wound gasket with a PTFE filler, which combines the strength of metal with the sealing properties of PTFE.

- If your primary focus is ensuring absolute fluid purity or sealing reactive fluids like LOX: You must use virgin PTFE or specially cleaned and prepared PTFE grades to prevent contamination or dangerous chemical reactions.

By understanding these principles, you can confidently specify a PTFE sealing solution that ensures safety and reliability in your cryogenic application.

Summary Table:

| Key Property | Benefit in Cryogenic Applications |

|---|---|

| Flexibility at Low Temperatures | Maintains sealing integrity, preventing brittle failure |

| Mechanical Strength | Withstands system pressure and thermal stress without cracking |

| Chemical Inertness | Resists corrosion and contamination from reactive cryogenic fluids |

| Predictable Thermal Contraction | Allows for reliable joint design to compensate for material shrinkage |

Ensure the reliability of your cryogenic systems with KINTEK's precision PTFE components.

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, and labware tailored for demanding environments like semiconductor, medical, and industrial cryogenic applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you receive components that deliver unmatched sealing performance, chemical resistance, and durability at extreme temperatures.

Contact us today to discuss your specific needs and let our team provide a solution that guarantees safety and efficiency in your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do PTFE seals perform in chemically aggressive environments? Ensure Unmatched Chemical Resistance

- What are PTFE rotary shaft seals and what are they designed for? Solve Extreme Sealing Challenges

- What are the weaknesses of glass fiber filled PTFE? A Guide to Material Trade-offs

- How is PTFE packing utilized in the food industry? Ensuring Food Safety and Efficiency

- What are the advantages of using PTFE lined ball valves in corrosive environments? Achieve Superior Corrosion Resistance

- What is PTFE commonly known as and can it be machined? Yes, with expert precision.

- How does PCTFE compare to PTFE for cryogenic applications? Choose the Right Material for Extreme Cold

- Why is PTFE considered an ideal material for demanding hydraulic and pneumatic applications? Ensure Superior Sealing Performance and Reliability