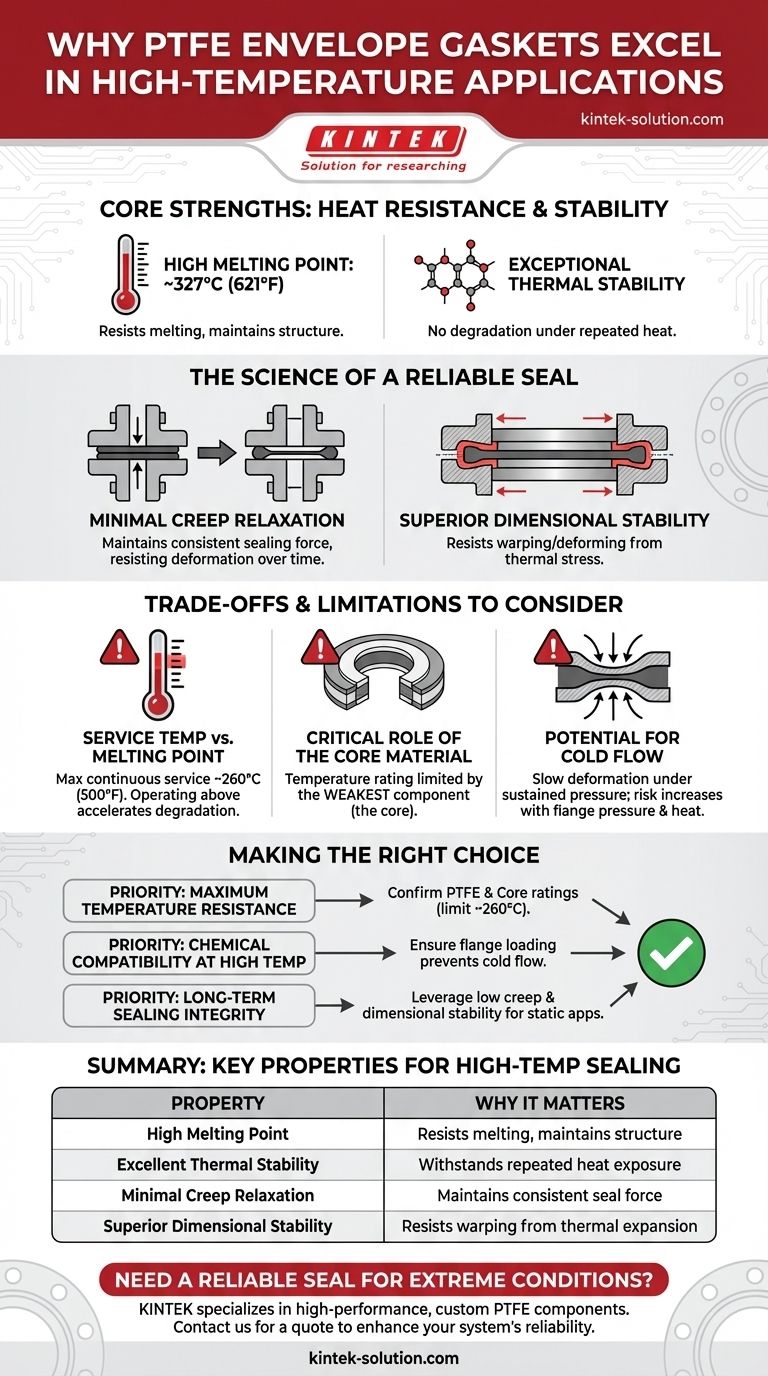

At its core, PTFE envelope gaskets are suitable for high-temperature applications because Polytetrafluoroethylene (PTFE) possesses an inherently high melting point and exceptional thermal stability. This allows the material to maintain its structural integrity and sealing performance under thermal stress that would cause other materials to degrade, deform, or fail.

The true value of PTFE in high-heat sealing is not just its ability to resist melting, but its capacity to maintain a consistent, reliable seal by resisting deformation (creep) and chemical breakdown under sustained high temperatures.

The Science Behind PTFE's Heat Resistance

To understand why PTFE is a superior choice for high-temperature gaskets, it's essential to look at its specific material properties. These characteristics work together to ensure reliability in extreme industrial conditions.

High Melting Point and Thermal Stability

PTFE has a very high melting point of approximately 327°C (621°F). This is a result of the strong chemical bonds between its carbon and fluorine atoms.

This robust molecular structure means the material does not easily break down or degrade when exposed to heat, giving it excellent thermal stability. This allows it to withstand repeated exposure to high temperatures without losing its fundamental properties.

Maintaining a Seal: Minimal Creep Relaxation

Creep relaxation is the tendency of a gasket material to lose its initial sealing force over time when compressed, a process that accelerates with heat.

PTFE exhibits minimal creep compared to many other polymers. This ensures that once the gasket is installed and tightened, it continues to exert a consistent sealing pressure against the flange faces, even in hot environments.

Dimensional Stability Under Thermal Stress

A critical function of a gasket is to perfectly fill the space between two flanges. Materials that expand, contract, or warp significantly with temperature changes can compromise this seal.

PTFE maintains its shape and dimensions exceptionally well when heated. This dimensional stability prevents the gasket from deforming or failing due to thermal expansion, a common issue with some metal components.

Understanding the Trade-offs and Limitations

While PTFE is highly capable, understanding its practical limitations is key to successful application and avoiding system failure. An envelope gasket is a composite product, and its performance depends on all of its parts.

Service Temperature vs. Melting Point

The melting point is the temperature at which the material becomes liquid, but the maximum continuous service temperature is lower.

For most PTFE applications, the practical upper limit for continuous use is around 260°C (500°F). Operating above this for extended periods can accelerate degradation and reduce the gasket's lifespan.

The Critical Role of the Core Material

A PTFE envelope gasket is not a solid piece of PTFE. It consists of a softer, more compressible core material (the insert) protected by a thin outer layer (the envelope) of PTFE.

The overall temperature rating of the gasket assembly is limited by the weakest component. If the core material cannot handle the operating temperature, the gasket will fail even if the PTFE envelope itself remains stable.

The Potential for Cold Flow

While PTFE has good creep resistance for a polymer, it is still susceptible to cold flow. This is a slow deformation or "flow" of the material under sustained mechanical pressure.

In applications with very high flange pressures combined with high temperatures, the risk of cold flow increases. This can eventually lead to a loss of sealing force and a potential leak.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the specific demands of your system.

- If your primary focus is maximum temperature resistance: Confirm that both the PTFE envelope and the core insert are rated for your operating temperature, keeping the continuous service limit of 260°C (500°F) in mind for long-term reliability.

- If your primary focus is chemical compatibility at high temperatures: PTFE's chemical inertness makes it an exceptional choice, but you must ensure your flange loading is correctly calculated to prevent cold flow.

- If your primary focus is long-term sealing integrity: The combination of PTFE's low creep relaxation and dimensional stability provides a reliable, long-lasting seal in static applications exposed to consistent heat.

By understanding these properties and limitations, you can confidently specify PTFE envelope gaskets to ensure the safety and reliability of your high-temperature systems.

Summary Table:

| Key Property | Why It Matters for High-Temp Sealing |

|---|---|

| High Melting Point (~327°C/621°F) | Resists melting and maintains structural integrity under extreme heat. |

| Excellent Thermal Stability | Withstands repeated high-temperature exposure without degrading. |

| Minimal Creep Relaxation | Maintains consistent sealing force over time, preventing leaks. |

| Superior Dimensional Stability | Resists warping or deforming due to thermal expansion. |

Need a reliable seal for extreme conditions?

KINTEK specializes in manufacturing high-performance, custom PTFE components, including envelope gaskets, seals, liners, and labware. Our precision production ensures your gaskets deliver superior heat resistance, chemical inertness, and long-term sealing integrity for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

From prototypes to high-volume orders, we provide the exact solution you need.

Contact KINTEK today for a quote and see how our PTFE expertise can enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the compression and rebound characteristics of ePTFE gaskets? Master Sealing for Demanding Flanges

- Why are PTFE O-Rings considered versatile for low-pressure, static applications? Unlock Superior Chemical and Thermal Resistance

- In which industries are PTFE machined parts commonly used? Critical Components for Extreme Conditions

- What is the temperature range for PTFE oil seals and conventional oil seals? A Guide to Extreme vs. Standard Performance

- What is the disadvantage of using glass as a filler in PTFE? The Critical Trade-off for Wear Resistance

- Why are PTFE seals preferred for high surface speed applications? Achieve Superior Sealing Performance

- In which applications are PTFE O-rings commonly used? Critical Seals for Extreme Environments

- What materials are used in the construction of PTFE-lined bearings? A Guide to Their 4-Layer Composite Design