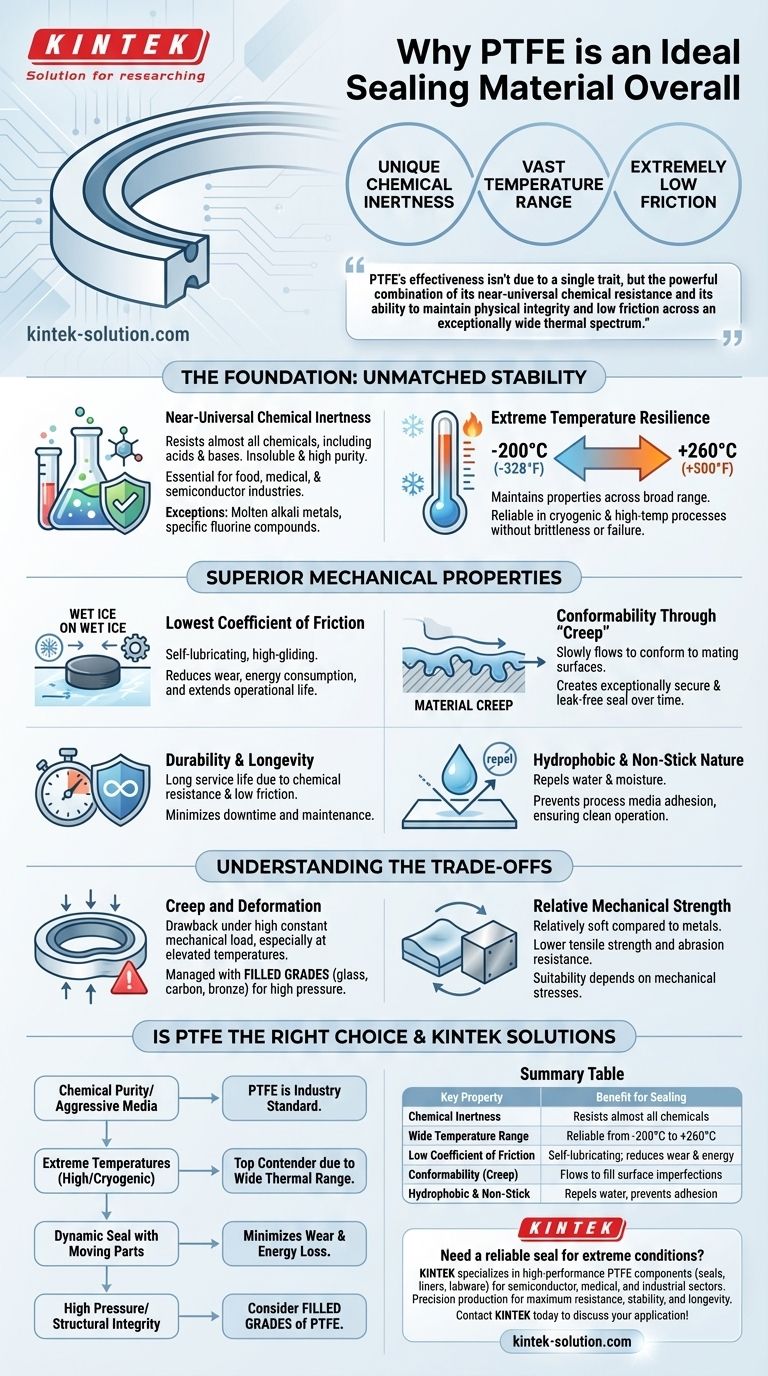

At its core, Polytetrafluoroethylene (PTFE) is an ideal sealing material because of its unique chemical inertness, vast temperature range, and extremely low friction. This powerful combination of properties allows PTFE to create a reliable, long-lasting seal in aggressive operating conditions where most other materials would quickly fail, from corrosive chemical processing to cryogenic applications.

PTFE's effectiveness isn't due to a single trait, but the powerful combination of its near-universal chemical resistance and its ability to maintain physical integrity and low friction across an exceptionally wide thermal spectrum.

The Foundation: Unmatched Chemical and Thermal Stability

The primary value of a sealing material is its ability to remain stable and functional within its operating environment. PTFE excels in this regard, setting a high standard for reliability under extreme conditions.

Near-Universal Chemical Inertness

PTFE is resistant to attack by almost all chemicals, including highly aggressive acids and bases. It is insoluble and possesses high intrinsic purity.

This means a PTFE seal will not degrade when exposed to corrosive fluids, nor will it contaminate a sensitive medium, making it essential for the food, medical, and semiconductor industries.

The only notable exceptions are molten alkali metals and certain reactive fluorine compounds under very specific conditions.

Extreme Temperature Resilience

PTFE maintains its critical properties across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used reliably in both high-temperature industrial processes and deep cryogenic applications without becoming brittle or losing its sealing capability.

Superior Mechanical Properties for Sealing

Beyond its stability, PTFE's physical characteristics are uniquely suited for creating and maintaining a tight, low-maintenance seal.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating or "high-gliding" ability is critical for dynamic seals with moving parts.

This property dramatically reduces wear and tear on the seal and mating components, lowers the energy required for movement, and prolongs the system's operational life.

Conformability Through "Creep"

Unlike materials that retain a strong "memory" of their original shape, PTFE exhibits material creep. This allows it to slowly flow and conform to the microscopic imperfections of a mating surface.

This unique characteristic results in an exceptionally secure and leak-free seal that adapts to its housing over time.

Durability and Longevity

The combination of chemical resistance and low friction gives PTFE seals a very long service life. They resist degradation and wear, which minimizes downtime and maintenance costs.

Hydrophobic and Non-Stick Nature

PTFE naturally repels water and moisture. Its non-stick surface prevents process media from adhering to the seal, ensuring clean operation and consistent performance.

Understanding the Trade-offs

No material is perfect for every scenario. Understanding PTFE's limitations is key to using it effectively.

Creep and Deformation

The same material creep that enhances conformability can be a drawback under high, constant mechanical loads, especially at elevated temperatures. The seal may slowly deform over time.

For high-pressure applications, this is often managed by using "filled" grades of PTFE, where materials like glass, carbon, or bronze are added to improve strength and creep resistance.

Relative Mechanical Strength

Compared to metals or high-performance engineering plastics, pure PTFE is a relatively soft material with lower tensile strength and abrasion resistance. Its suitability depends on the mechanical stresses involved in the specific application.

Is PTFE the Right Choice for Your Application?

Choosing a sealing material requires matching its properties to your primary operational goal.

- If your primary focus is chemical purity or aggressive media: PTFE is an industry standard due to its near-total inertness.

- If your application involves extreme temperatures (high or cryogenic): PTFE's ability to maintain its core properties across a vast thermal range makes it a top contender.

- If you are designing a dynamic seal with moving parts: The exceptionally low friction of PTFE minimizes wear and energy loss, extending the life of the system.

- If your application involves high pressure or requires high structural integrity: You should consider filled grades of PTFE, as pure PTFE may exhibit excessive creep or deformation.

Ultimately, selecting PTFE is a strategic choice for applications where reliability in extreme chemical and thermal environments is non-negotiable.

Summary Table:

| Key Property | Benefit for Sealing |

|---|---|

| Chemical Inertness | Resists almost all chemicals, ideal for corrosive and high-purity applications. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Coefficient of Friction | Self-lubricating; reduces wear and energy consumption in dynamic seals. |

| Conformability (Creep) | Flows to fill surface imperfections, creating a superior, leak-free seal. |

| Hydrophobic & Non-Stick | Repels water and prevents media adhesion for clean, consistent operation. |

Need a reliable seal for extreme conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom solutions from prototypes to high-volume orders.

Our precision production ensures your seals deliver maximum chemical resistance, thermal stability, and longevity.

Contact KINTEK today to discuss your specific application requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating