Simply put, PTFE is an excellent electrical insulator for construction because it combines exceptional dielectric strength with an almost unparalleled resistance to the harsh conditions found in building environments. It can insulate against 500 volts per thousandth of an inch while simultaneously withstanding extreme temperatures, chemical exposure, and moisture, ensuring long-term reliability and safety.

The true value of PTFE isn't just its ability to insulate electricity; it's the material's power to maintain that insulation integrity, without degrading, over decades of exposure to the heat, chemicals, and physical stress inherent in any construction project.

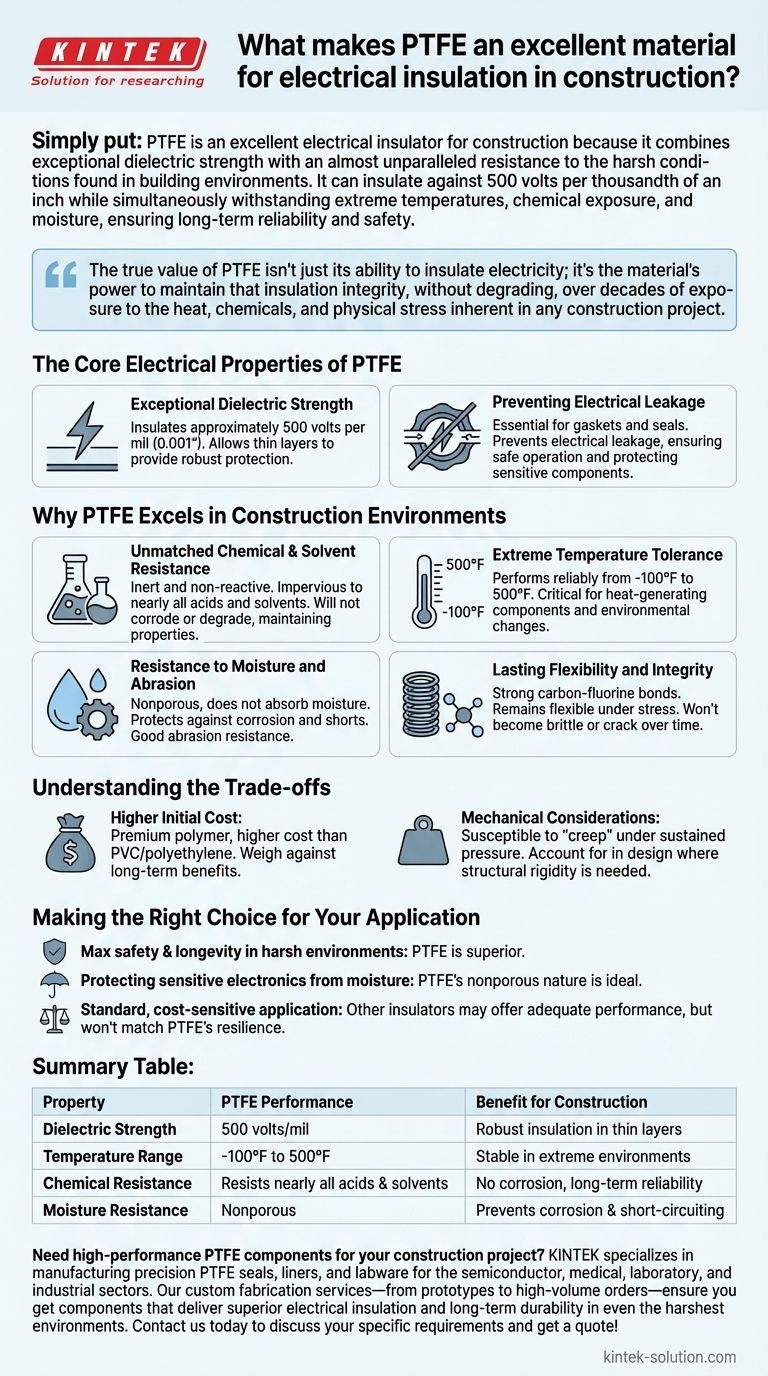

The Core Electrical Properties of PTFE

The primary function of an insulator is to prevent the flow of electricity where it isn't wanted. PTFE accomplishes this with remarkable effectiveness.

Exceptional Dielectric Strength

Dielectric strength is the measure of a material's ability to withstand high voltage before it breaks down and begins to conduct electricity.

PTFE has an extremely high dielectric strength, capable of insulating approximately 500 volts per mil (one-thousandth of an inch). This allows for very thin layers of insulation to provide robust protection.

Preventing Electrical Leakage

This high insulating capability makes PTFE essential for components like gaskets and seals within electrical equipment and electronic devices.

By using PTFE, manufacturers can effectively prevent electrical leakage, ensuring both the safe operation of the equipment and the protection of sensitive internal components.

Why PTFE Excels in Construction Environments

A building is a demanding environment. Materials are subjected to wide temperature swings, potential chemical exposure, and moisture over their entire lifespan. PTFE is uniquely suited to handle these challenges.

Unmatched Chemical & Solvent Resistance

PTFE is a highly inert and non-reactive material, making it impervious to nearly all acids, solvents, and other chemicals it might encounter during or after construction.

This chemical resistance ensures the insulation will not corrode or degrade, maintaining its protective properties for decades.

Extreme Temperature Tolerance

The material can perform reliably across an incredible temperature range, from approximately -100°F to 500°F (-73°C to 260°C).

This stability is critical for applications near heat-generating electrical components or in structures exposed to significant environmental temperature changes.

Resistance to Moisture and Abrasion

PTFE is nonporous, meaning it does not absorb moisture. This protects electrical parts from the corrosion and short-circuiting that moisture can cause.

Its robust molecular structure also provides good abrasion resistance, preventing physical wear from damaging the insulation during installation or maintenance.

Lasting Flexibility and Integrity

The carbon-fluorine bonds that form PTFE are incredibly strong and remain flexible even when subjected to physical stress.

This quality ensures the insulation won't become brittle or crack over time, providing a durable and long-lasting shield for electrical systems.

Understanding the Trade-offs

While PTFE's properties are exceptional, no material is perfect for every situation. A clear-eyed assessment requires acknowledging its practical limitations.

Higher Initial Cost

PTFE is a premium performance polymer, and its manufacturing cost is significantly higher than that of more common insulators like PVC or polyethylene.

This cost must be weighed against the long-term benefits of its superior durability and reliability, especially in critical or hard-to-access applications.

Mechanical Considerations

While flexible, PTFE is a relatively soft material that can be susceptible to "creep"—a slow deformation under sustained pressure.

For applications requiring high structural rigidity in addition to insulation, design considerations must account for this characteristic.

Making the Right Choice for Your Application

Selecting the correct material comes down to matching its properties to the specific demands of the project.

- If your primary focus is maximum safety and longevity in a harsh environment: PTFE is the superior choice for its unmatched chemical, thermal, and electrical stability.

- If your primary focus is protecting sensitive electronics from moisture and contamination: PTFE's nonporous and inert nature makes it the ideal material for high-performance gaskets and seals.

- If your primary focus is a standard, cost-sensitive application with controlled conditions: You may find that other insulators offer adequate performance, but they will not match PTFE's resilience.

Ultimately, PTFE's unique combination of properties makes it the premier material for ensuring the highest degree of electrical safety and system integrity in demanding construction projects.

Summary Table:

| Property | PTFE Performance | Benefit for Construction |

|---|---|---|

| Dielectric Strength | 500 volts/mil | Robust insulation in thin layers |

| Temperature Range | -100°F to 500°F | Stable in extreme environments |

| Chemical Resistance | Resists nearly all acids & solvents | No corrosion, long-term reliability |

| Moisture Resistance | Nonporous | Prevents corrosion & short-circuiting |

Need high-performance PTFE components for your construction project?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get components that deliver superior electrical insulation and long-term durability in even the harshest environments.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability