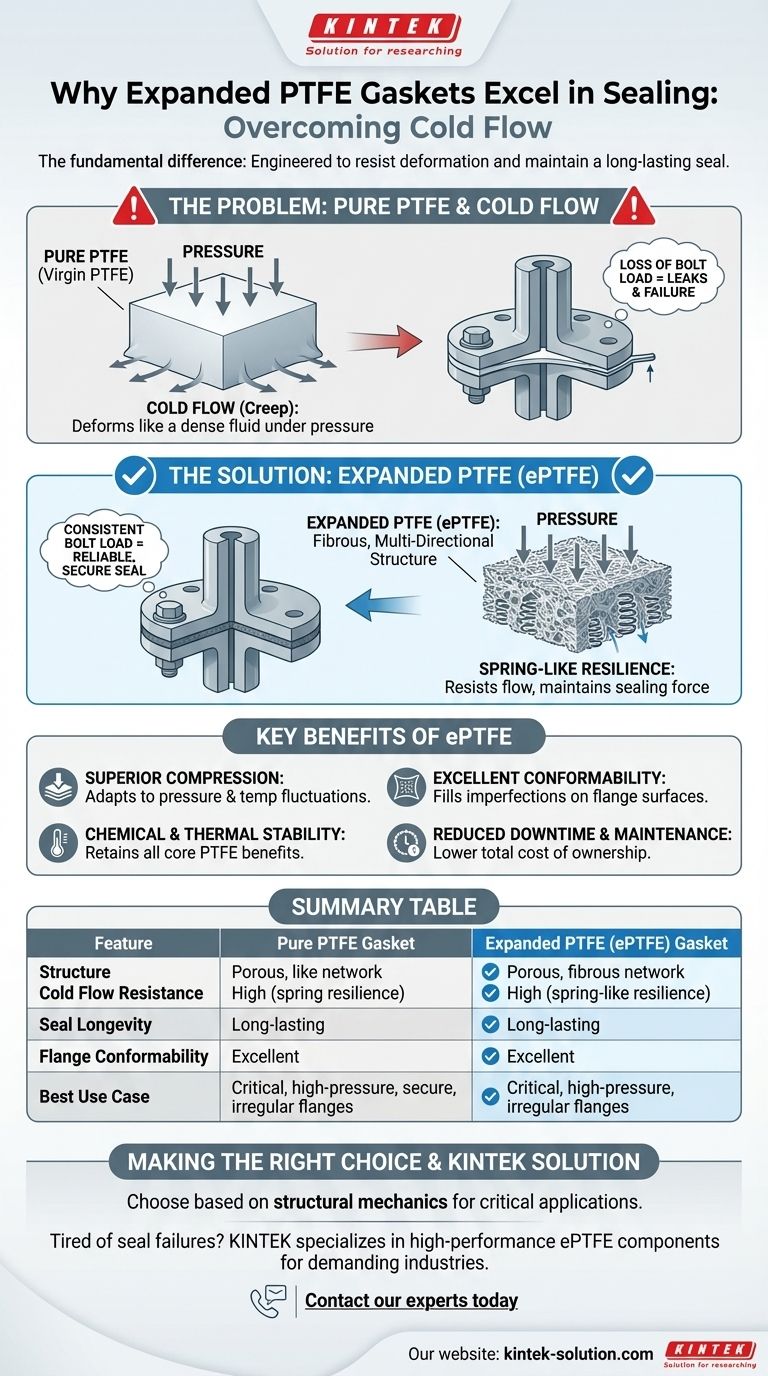

The fundamental difference is that expanded PTFE (ePTFE) gaskets are specifically engineered to overcome the primary weakness of pure PTFE: its tendency to deform and "flow" away from pressure. The unique porous, fibrous structure of ePTFE allows it to compress and rebound like a spring, maintaining a tight, long-lasting seal where a solid pure PTFE gasket would slowly loosen and fail.

The core issue is cold flow. While pure PTFE is exceptionally chemically resistant, it behaves like a very dense fluid under pressure, slowly creeping out of the seal. Expanded PTFE's manufacturing process creates a multi-directional fibrous structure that physically resists this flow, ensuring bolt torque is maintained and the seal remains secure over time.

The Inherent Problem with Pure PTFE: Cold Flow

Pure Polytetrafluoroethylene (PTFE) is a remarkable material, but its physical form presents a significant challenge in many sealing applications.

### What Defines Pure PTFE?

Pure PTFE, often called virgin PTFE, is a solid polymer. It is renowned for its near-universal chemical inertness, high-temperature stability, and extremely low friction.

This combination of properties makes it an obvious candidate for gasket material. It is soft and can readily deform to fill small gaps between surfaces.

### The Concept of "Cold Flow" (Creep)

The softness of solid PTFE is also its biggest liability in a gasket. When you tighten the bolts on a flange, the compressive force squeezes the gasket.

Under this constant pressure, solid PTFE material will slowly and permanently deform, or "flow," away from the point of highest pressure. This process, known as creep or cold flow, happens even at room temperature.

### The Consequence: Loss of Sealing Integrity

As the gasket material flows outward, it becomes thinner under the bolts. This reduces the compressive force holding the seal together, a phenomenon known as loss of bolt load.

This loss of tightness eventually creates a path for leaks, requiring frequent re-tightening of bolts and posing a significant reliability risk, especially in critical or high-pressure systems.

How Expanded PTFE Solves the Sealing Challenge

Expanded PTFE is not a different chemical; it is the same polymer transformed through a specialized manufacturing process to create a vastly superior sealing material.

### A Unique Fibrous Structure

During manufacturing, solid PTFE is physically stretched, or expanded, in a controlled way. This process transforms the solid block into a microporous material composed of countless interwoven fibers.

This fibrous, multi-directional structure is the key to its enhanced performance. It is incredibly soft and compressible yet structurally strong.

### Superior Compression and Resilience

Unlike solid PTFE which just deforms, the fibrous structure of ePTFE acts like a microscopic spring. When compressed, the fibers compact.

This structure gives ePTFE excellent compression resilience. It can adapt to pressure and temperature fluctuations, maintaining an active sealing force against the flange faces where pure PTFE would have already permanently flowed away.

### Conforming to Imperfect Surfaces

The exceptional softness and compressibility of ePTFE allow it to conform perfectly to even irregular or damaged flange surfaces.

It effectively fills in minor scratches, pitting, and warping, creating a reliable seal where a more rigid gasket might fail. This can help extend the service life of older equipment.

Understanding the Trade-offs

While ePTFE offers superior sealing performance, it's essential to understand the context of your application.

### When Pure PTFE Can Suffice

For low-pressure, non-critical applications where the consequences of a slow leak are minimal, a pure PTFE gasket may be acceptable. Its primary advantage is a lower initial purchase price.

### The Cost vs. Reliability Equation

Expanded PTFE is a more advanced material and is generally more expensive. However, this higher upfront cost is often offset by dramatically improved reliability.

The total cost of ownership is lower when you factor in reduced downtime, prevention of product loss from leaks, and lower maintenance labor for re-tightening bolts.

### Chemical and Thermal Properties Remain Identical

Crucially, the expansion process is purely physical. Expanded PTFE retains the exact same outstanding chemical resistance and wide operational temperature range as pure, solid PTFE. You sacrifice none of the material's core benefits.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the demands of the service.

- If your primary focus is maximum seal reliability and safety: Choose expanded PTFE. Its resistance to cold flow is essential for preventing leaks in critical, hazardous, or high-pressure systems.

- If you are sealing old, worn, or damaged flanges: Choose expanded PTFE. Its superior conformability will create a tight seal where more rigid materials would fail.

- If your primary focus is the lowest initial cost on a non-critical system: Pure PTFE is a viable option, but you must plan for periodic bolt re-torquing and accept a higher risk of leaks over time.

Choosing a gasket based on its structural mechanics, not just its chemical compatibility, is the key to achieving a truly reliable and long-lasting seal.

Summary Table:

| Feature | Pure PTFE Gasket | Expanded PTFE (ePTFE) Gasket |

|---|---|---|

| Structure | Solid polymer block | Porous, fibrous network |

| Cold Flow Resistance | Low (prone to creep) | High (spring-like resilience) |

| Seal Longevity | Shortens due to bolt load loss | Long-lasting, maintains seal integrity |

| Flange Conformability | Moderate | Excellent (fills imperfections) |

| Best Use Case | Low-pressure, non-critical systems | Critical, high-pressure, or irregular flanges |

Tired of seal failures due to cold flow? KINTEK specializes in manufacturing high-performance expanded PTFE components, including custom gaskets designed to withstand demanding conditions in semiconductor, medical, laboratory, and industrial applications. Our precision engineering ensures your seals remain reliable under pressure.

Contact our experts today to discuss a custom ePTFE sealing solution for your critical application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry