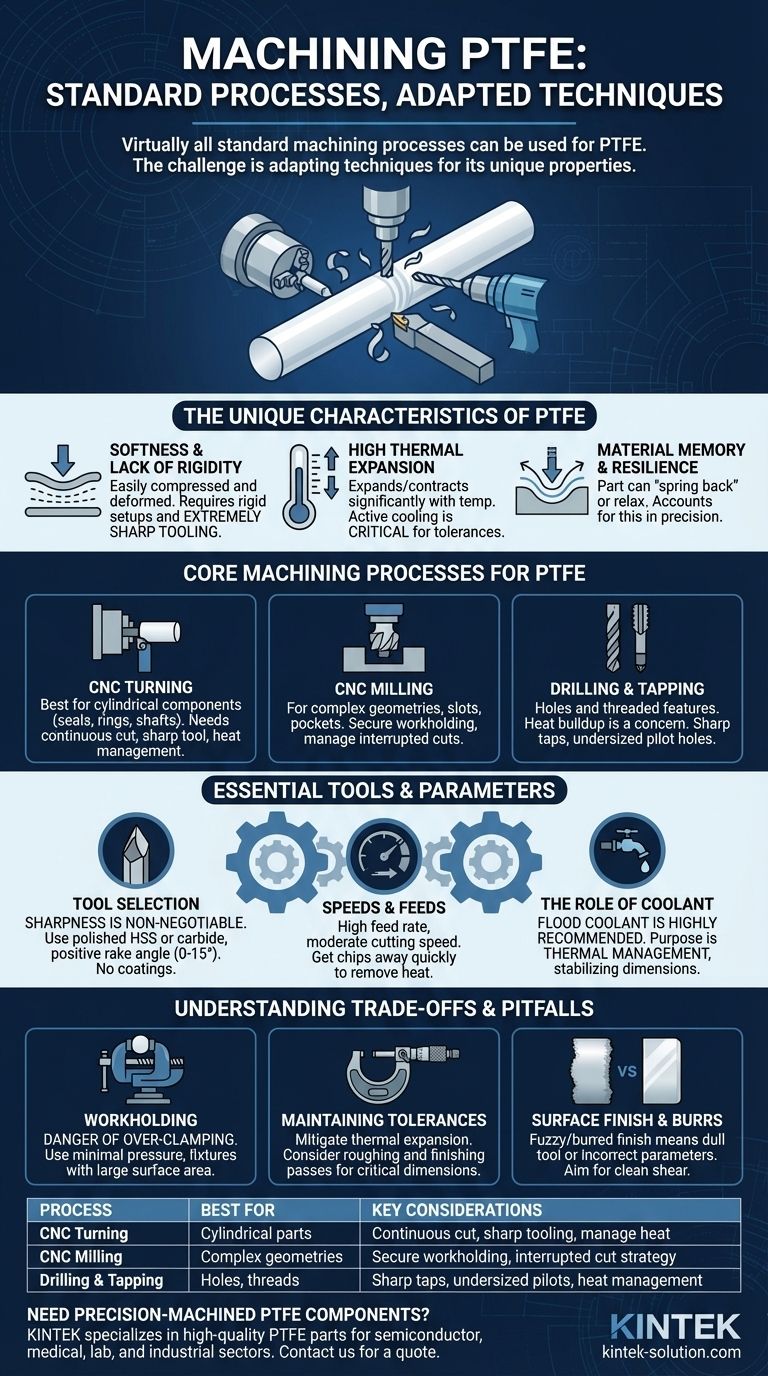

Virtually all standard machining processes can be used for PTFE. Polytetrafluoroethylene is a soft, low-friction polymer that is readily cut, turned, milled, and drilled using conventional equipment, including CNC machines. The true challenge is not in what processes you can use, but in how you adapt your technique to accommodate the material's unique properties.

The core principle of machining PTFE is managing its distinct characteristics: high thermal expansion, inherent softness, and lack of rigidity. While the processes are standard, success requires specialized tooling, specific speed and feed strategies, and careful workholding to prevent deformation and maintain dimensional accuracy.

The Unique Machining Characteristics of PTFE

Understanding why PTFE behaves the way it does is the first step toward machining it effectively. Its properties are fundamentally different from metals and even other plastics.

Softness and Lack of Rigidity

PTFE is an exceptionally soft material. This means it can easily be compressed, deformed, or pushed away by cutting tool pressure rather than being cleanly cut.

This characteristic makes rigid machine setups and extremely sharp tooling absolutely essential.

High Thermal Expansion

PTFE expands and contracts with temperature changes far more than most materials. The heat generated during a cutting operation can cause the material to expand significantly, ruining tolerances.

Once the part cools, it will shrink, resulting in a final dimension that is smaller than what was measured during the cut. This makes active cooling a critical process variable.

Material Memory and Resilience

Due to its resilience, a machined PTFE part can conform to mating surfaces, which is why extremely tight tolerances are not always necessary.

However, this same property means the material can "spring back" slightly after a cut or relax after being released from a fixture, which must be accounted for when precision is required.

Core Machining Processes for PTFE

Standard CNC and manual equipment are perfectly suitable for PTFE. The following processes are the most common.

CNC Turning

CNC turning is ideal for producing cylindrical components like seals, rings, insulators, and shafts. The continuous cutting action works well with PTFE, provided the tool is sharp enough to create a smooth shearing motion.

CNC Milling

Milling is used to create more complex geometries, slots, pockets, and flat surfaces. Because milling involves an interrupted cut, it's vital to ensure the workpiece is securely held without being distorted.

Drilling and Tapping

Drilling holes in PTFE is straightforward, but heat buildup is a major concern, especially with deeper holes. Tapping threads requires sharp taps and often drilling the pilot hole slightly undersized to account for the material's tendency to deform.

Essential Tools and Parameters for Success

Your choice of tooling and machine settings will determine the quality of the final part. The goal is always to shear the material cleanly with minimal heat input.

Tool Selection: Sharpness is Non-Negotiable

The single most important factor is tool sharpness. A dull tool will plow through the material instead of cutting it, generating excess heat and a poor surface finish.

Use high-speed steel (HSS) or carbide tools with very sharp, polished cutting edges. A positive rake angle (0–15 degrees) reduces cutting forces and helps peel the material away smoothly. Uncoated tools are often preferred as some coatings can increase friction.

Speeds and Feeds: A Counterintuitive Approach

The strategy for PTFE is to get the chip away from the part as quickly as possible before it can transfer heat. This often means using a high feed rate combined with a moderate cutting speed.

Recommended starting points are cutting speeds of 200 to 500 surface feet per minute (SFM) and feed rates of 0.002 to 0.010 inches per revolution. These are only starting points; always adjust based on the resulting chip formation and surface finish.

The Role of Coolant

Using a flood coolant system is highly recommended. Its primary purpose is not lubrication but thermal management. The coolant carries heat away from the workpiece, stabilizing its dimensions and preventing inaccurate cuts due to thermal expansion.

Understanding the Trade-offs and Pitfalls

Avoiding common mistakes is crucial for efficient and accurate PTFE machining.

Workholding: The Danger of Over-clamping

Because PTFE is so soft, it is very easy to distort it in a vise or chuck. Apply minimal clamping pressure—just enough to hold the part securely.

Using fixtures with a large surface area can help distribute the clamping force and minimize part deformation.

Maintaining Tolerances

Achieving tight tolerances is possible but requires strict process control. The key is to mitigate thermal expansion through sharp tools, proper speeds and feeds, and generous coolant application.

For critical dimensions, consider performing roughing passes to remove most of the material, followed by a light finishing pass after the part has stabilized.

Surface Finish and Burrs

A fuzzy or burred surface finish is a clear sign that your cutting tool is dull or your parameters are incorrect. PTFE should machine with a clean, almost glossy finish when the tool is shearing the material properly.

Making the Right Choice for Your Goal

Your approach should be tailored to the requirements of your specific application.

- If your primary focus is rapid prototyping or non-critical parts: Standard sharp HSS tools will work well, and you can focus on higher material removal rates.

- If your primary focus is high-precision components: Invest in dedicated sharp carbide tooling, use generous coolant, and plan for separate roughing and finishing passes to manage thermal stability.

- If your primary focus is high-volume production: Consistency is key. Utilize CNC equipment with flood coolant and establish a strict tool replacement schedule to ensure cutting edges remain perfectly sharp.

Mastering PTFE machining comes down to respecting the material's unique properties and adapting your standard techniques accordingly.

Summary Table:

| Process | Best For | Key Considerations |

|---|---|---|

| CNC Turning | Cylindrical parts (seals, rings, shafts) | Continuous cut, sharp tooling, manage heat |

| CNC Milling | Complex geometries, slots, pockets | Secure workholding, interrupted cut strategy |

| Drilling & Tapping | Holes and threaded features | Sharp taps, undersized pilot holes, heat management |

Need Precision-Machined PTFE Components?

KINTEK specializes in manufacturing high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the nuances of machining PTFE and leverage our expertise to deliver parts with exceptional dimensional accuracy, from prototypes to high-volume production runs.

Let us put our precision production and custom fabrication capabilities to work for you.

Contact our team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability