The unique design of a PTFE bearing lies in its bespoke nature; each one is an engineered solution tailored specifically to a project's load, movement, environmental conditions, and structural integration requirements. Unlike standardized components, they are almost never reused because their material composition and physical form are precision-engineered for a single, unique application.

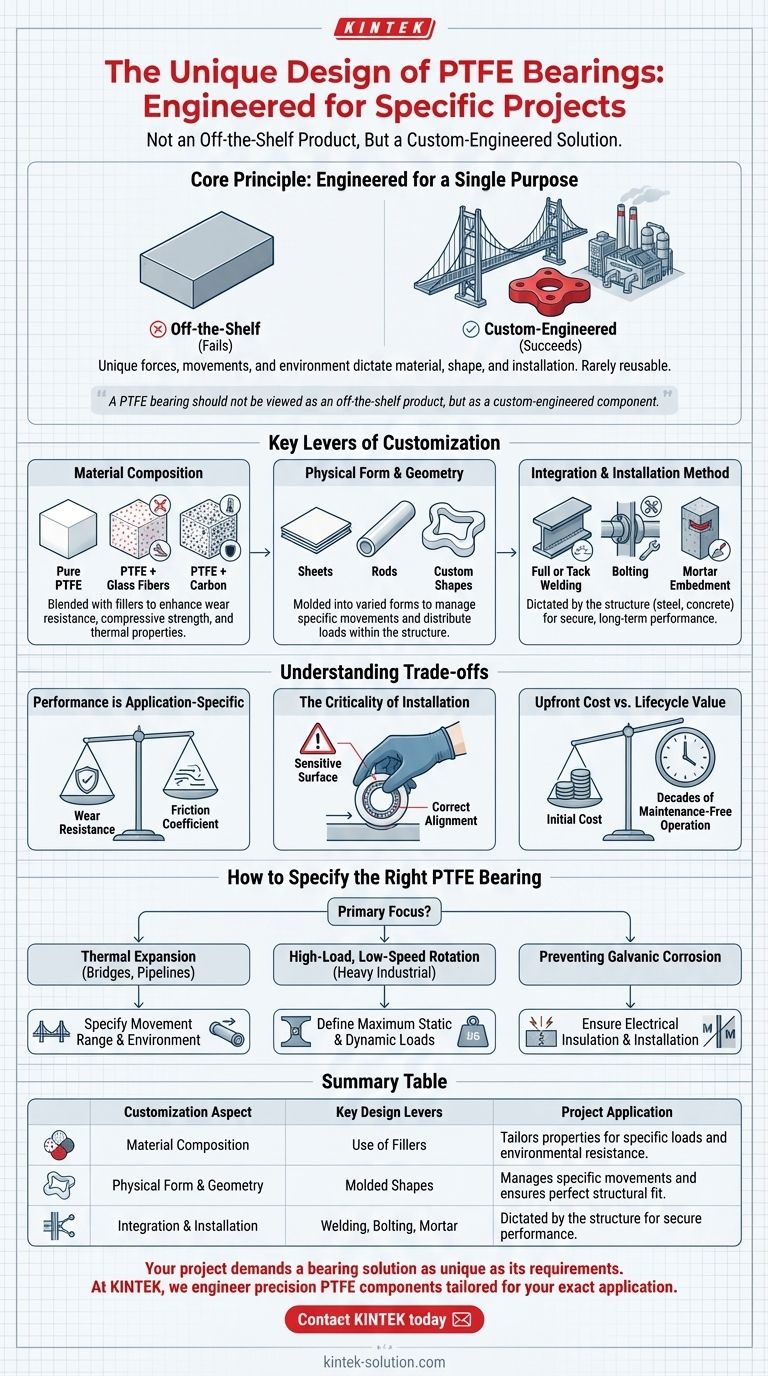

A PTFE bearing should not be viewed as an off-the-shelf product, but as a custom-engineered component. Its uniqueness stems from the fact that its material, shape, and installation method are all dictated by the specific problem it is designed to solve.

The Core Principle: Engineered for a Single Purpose

Polytetrafluoroethylene (PTFE) bearings are fundamental components in major structures like bridges and industrial facilities. Their design process is inherently custom because the forces and movements they must manage are unique to each structure.

Why Off-the-Shelf Fails

Standardized bearings are designed for common, repeatable applications. In contrast, a PTFE slide bearing for a bridge must accommodate that specific bridge's thermal expansion, live load deflection, and seismic movement.

These project-specific parameters mean that a bearing designed for one application is fundamentally unsuitable for another, which is why they are rarely ever reused.

The Designer-Manufacturer Partnership

The responsibility for a successful design falls on the manufacturer, who must interpret the project's engineering specifications. This requires a close partnership to translate structural needs into a tangible, reliable bearing assembly.

Key Levers of Customization

The uniqueness of a PTFE bearing's design is achieved through the manipulation of three key variables: its material composition, its physical geometry, and its method of integration.

Material Composition: The Power of Fillers

Pure PTFE is rarely sufficient for high-demand structural applications. Its properties are enhanced by blending it with fillers.

This material customization is a primary design lever. Glass fibers can be added to dramatically increase wear resistance, while carbon can be introduced to improve thermal conductivity and compressive strength.

Physical Form and Geometry

PTFE's versatility allows it to be molded into a wide array of forms, such as sheets, rods, and custom shapes.

The final form of the bearing assembly is dictated by the structure it serves. It is shaped to manage specific movements, distribute loads evenly, and fit perfectly within the larger structural system.

Integration and Installation Method

How a bearing connects to the structure is a critical design consideration. The chosen method directly influences the bearing's final assembly and materials.

Common installation methods, each requiring a unique design approach, include:

- Full or Tack Welding: For integration into steel superstructures.

- Bolting: For mechanical fastening where welding is not feasible.

- Mortar Embedment: For seating the bearing within concrete foundations or piers.

Understanding the Trade-offs

While highly effective, the custom nature of PTFE bearings introduces specific considerations that must be managed to ensure long-term performance and reliability.

Performance is Application-Specific

A filler that enhances one property, like wear resistance, may slightly alter another, such as the coefficient of friction. The design must balance these properties to achieve the optimal performance for the project's specific needs, not for general-purpose use.

The Criticality of Installation

The design's effectiveness is contingent on proper installation. The low-friction PTFE surface is sensitive and must be protected from damage, weld splatter, or contamination during construction. Improper alignment or surface preparation can compromise the entire system.

Upfront Cost vs. Lifecycle Value

Custom engineering carries a higher initial cost than a standardized part. However, this is offset by immense long-term value. A correctly designed and installed PTFE bearing provides decades of maintenance-free operation, corrosion resistance, and reliable performance.

How to Specify the Right PTFE Bearing

To ensure you get the right component, your specification must be driven by the primary problem you need to solve.

- If your primary focus is accommodating thermal expansion (e.g., bridges, pipelines): Specify the precise movement range and environmental conditions to ensure the right material filler and geometry are selected.

- If your primary focus is high-load, low-speed rotation (e.g., heavy industrial pivots): Define the maximum static and dynamic loads so the manufacturer can engineer for sufficient compressive strength and wear resistance.

- If your primary focus is preventing galvanic corrosion between dissimilar metals: Ensure the design provides complete electrical insulation and is matched with an installation method that maintains this separation.

By understanding these core principles, you can ensure your PTFE bearing is not just a component, but a perfectly tailored solution for your project's unique demands.

Summary Table:

| Customization Aspect | Key Design Levers | Project Application |

|---|---|---|

| Material Composition | Use of fillers (e.g., glass for wear, carbon for strength) | Tailors properties for specific loads and environmental resistance |

| Physical Form & Geometry | Molded into sheets, rods, or custom shapes | Manages specific movements and ensures perfect structural fit |

| Integration & Installation | Welding, bolting, or mortar embedment | Dictated by the structure (steel, concrete) for secure, long-term performance |

Your project demands a bearing solution as unique as its requirements. At KINTEK, we don't just supply parts; we engineer precision PTFE components—from seals and liners to custom bearings—that are tailored for your exact application in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a component designed for decades of maintenance-free, reliable performance.

Contact KINTEK today to discuss your project's specific needs and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support