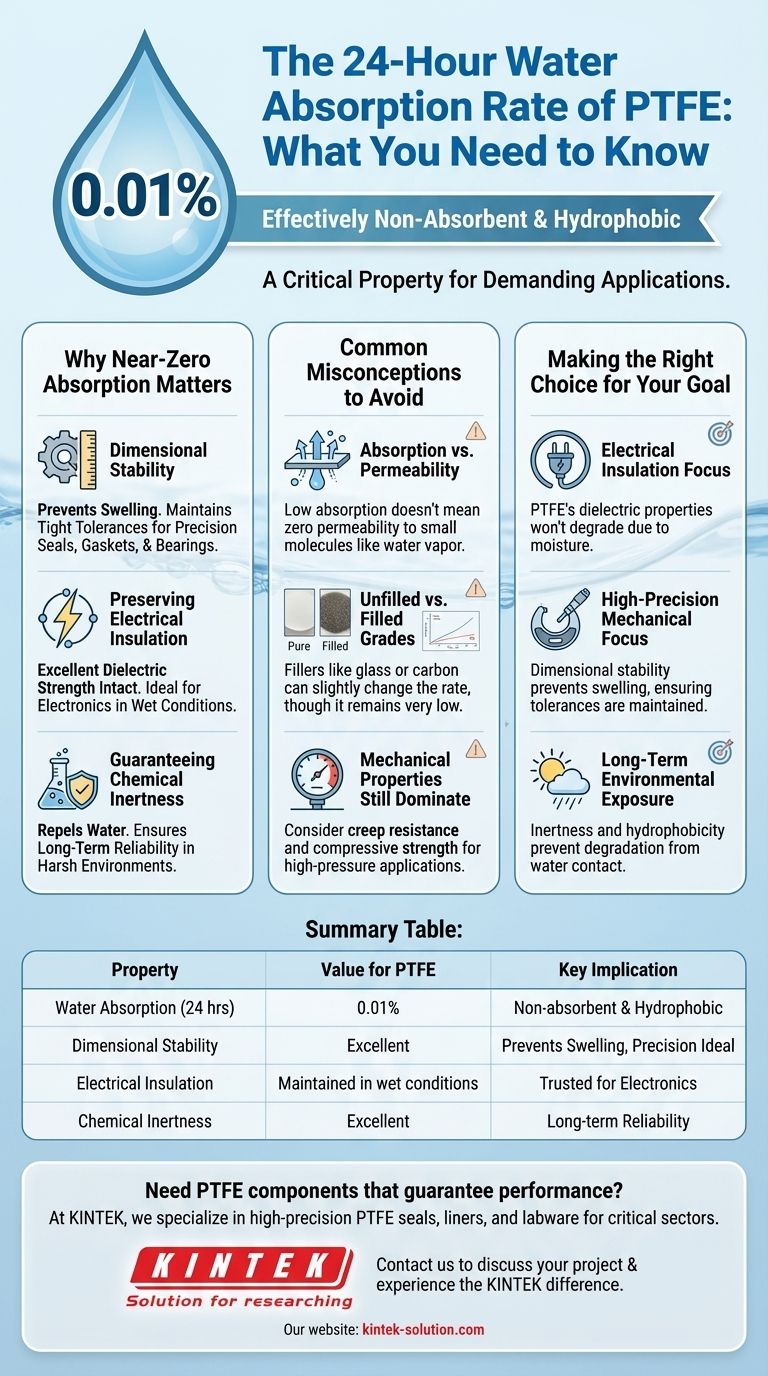

In short, the water absorption rate of Polytetrafluoroethylene (PTFE) after 24 hours of immersion is 0.01%. This exceptionally low figure means the material is effectively non-absorbent and hydrophobic, a critical property that underpins its performance in a wide range of demanding applications.

For practical engineering purposes, a water absorption rate of 0.01% is considered negligible. This isn't just a technical specification; it's the reason PTFE maintains its exceptional dimensional stability and electrical insulation properties, even when fully submerged in water.

Why Near-Zero Absorption Matters

The ability of a material to resist water is a fundamental indicator of its stability. For PTFE, this property is not an afterthought—it is central to its value as an engineering polymer.

The Impact on Dimensional Stability

When materials absorb moisture, they tend to swell. This change in size, even if minor, can be catastrophic for high-precision components.

Because PTFE absorbs virtually no water, its physical dimensions remain constant regardless of ambient humidity or direct water contact. This makes it an ideal material for critical seals, gaskets, and bearings where tight tolerances are non-negotiable.

Preserving Electrical Insulation

Water is conductive and significantly compromises the performance of insulating materials. Many plastics that are good insulators in dry conditions fail when moisture is introduced.

PTFE's resistance to water ensures its excellent dielectric strength and insulating properties remain intact. This is why it is trusted for high-frequency electronics, cable insulation, and connectors used in wet or humid environments.

Guaranteeing Chemical Inertness

Water can be a catalyst for chemical reactions or cause degradation in lesser materials. PTFE's hydrophobic nature is a key part of its renowned chemical inertness.

It repels water instead of absorbing it, preventing moisture from compromising its material structure. This ensures long-term reliability in applications from laboratory equipment to outdoor architectural membranes.

Common Misconceptions to Avoid

While its water resistance is exceptional, it's important to understand the complete context to make sound engineering decisions.

Absorption vs. Permeability

Low absorption does not mean zero permeability. While PTFE does not "soak up" water, very small molecules like water vapor can still slowly pass through it over time, a factor to consider in applications like high-vacuum or gas barriers.

Unfilled vs. Filled Grades

The 0.01% figure applies to pure, virgin PTFE. When fillers like glass, carbon, or bronze are added to enhance mechanical properties (e.g., wear resistance, compressive strength), the water absorption rate can change slightly. However, it almost always remains extremely low.

Mechanical Properties Still Dominate

Low water absorption does not automatically make PTFE the best choice for every wet application. In high-pressure sealing, for example, mechanical properties like creep resistance (resistance to slow deformation under load) and compressive strength are often more critical design factors.

Making the Right Choice for Your Goal

Selecting a material requires aligning its core properties with the primary demands of your application.

- If your primary focus is electrical insulation in variable humidity: PTFE is a premier choice because its dielectric properties will not degrade due to moisture.

- If your primary focus is high-precision mechanical components: PTFE's dimensional stability, guaranteed by its non-absorbent nature, prevents swelling and ensures tolerances are maintained.

- If your primary focus is long-term environmental exposure: PTFE's inertness and hydrophobicity make it a reliable material that will not weaken or degrade from contact with water.

Ultimately, PTFE's exceptionally low water absorption is a cornerstone of its predictability and performance in critical engineering roles.

Summary Table:

| Property | Value for PTFE | Key Implication |

|---|---|---|

| Water Absorption (24 hrs) | 0.01% | Effectively non-absorbent and hydrophobic |

| Dimensional Stability | Excellent | Prevents swelling; ideal for precision seals and gaskets |

| Electrical Insulation | Maintained in wet conditions | Trusted for high-frequency electronics and cable insulation |

| Chemical Inertness | Excellent | Long-term reliability in harsh environments |

Need PTFE components that guarantee performance in demanding environments?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver the critical hydrophobic properties and dimensional stability your applications require, from prototypes to high-volume production.

Contact us today to discuss your project and experience the KINTEK difference in precision and reliability.

Visual Guide

Related Products

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What does PTFE stand for? The Science Behind the Super-Material

- In which industries can PTFE be used due to its hygienic properties? Ensure Purity and Safety in Food, Pharma, and Medical

- What is PTFE and what are its common uses? A Guide to the High-Performance Polymer