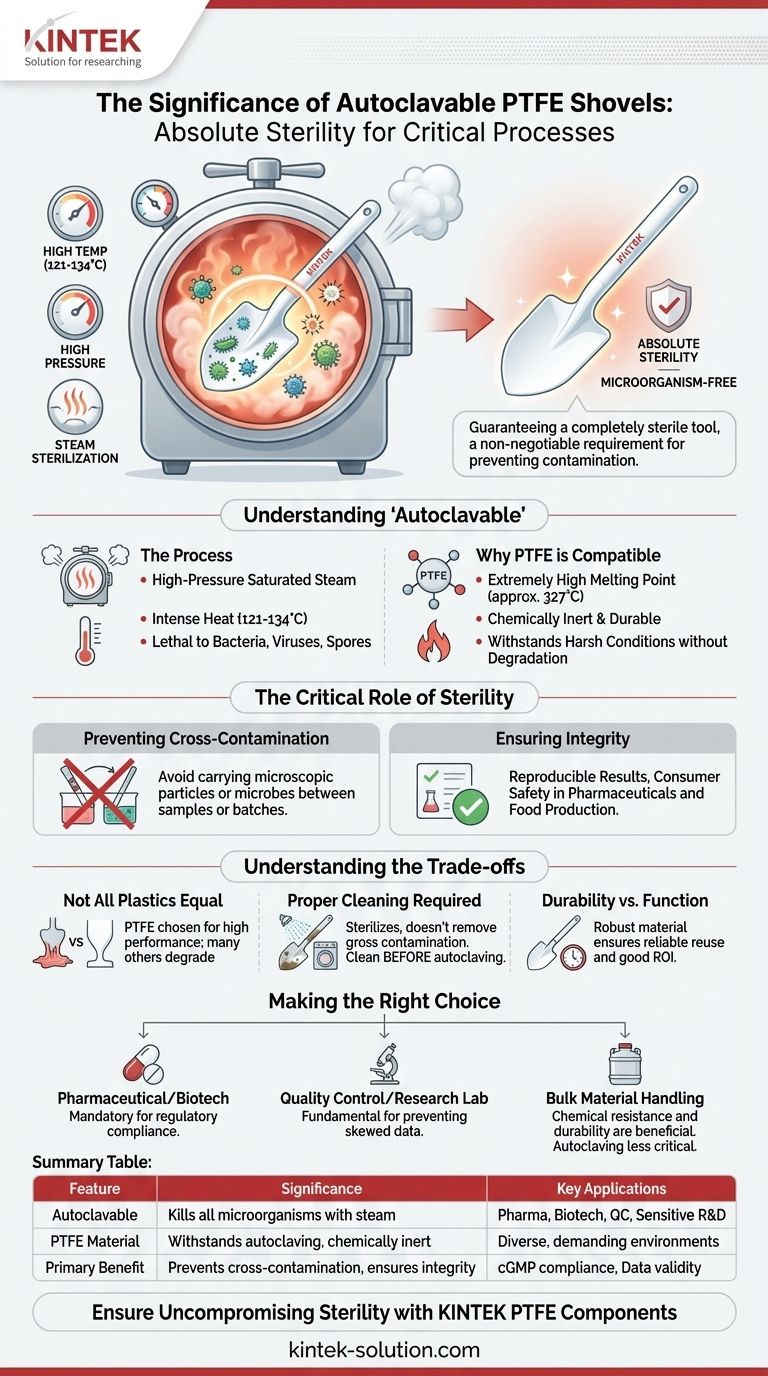

In short, the significance is absolute sterility. The autoclavable nature of PTFE (Polytetrafluoroethylene) shovels means they can be subjected to high-pressure saturated steam at high temperatures, a process that effectively kills all microorganisms. This guarantees the tool is completely sterile, which is a non-negotiable requirement for preventing contamination in sensitive laboratory, pharmaceutical, or manufacturing environments.

In environments where purity is paramount, a tool is only as reliable as its sterility. The ability to autoclave a PTFE shovel transforms it from a simple scoop into a scientifically valid instrument capable of maintaining the integrity of your entire process.

What "Autoclavable" Actually Means

To grasp the full significance, it's important to understand the process and why PTFE is uniquely suited for it. This isn't just about simple cleaning; it's about terminal sterilization.

The Process of Autoclaving

An autoclave is essentially a high-pressure chamber that uses steam heated to temperatures typically around 121-134°C (250-273°F). This combination of intense heat and pressure is lethal to bacteria, viruses, and spores that simple washing or chemical disinfectants might miss.

Why PTFE is Compatible

The key lies in the material properties of PTFE. It has an extremely high melting point (around 327°C or 621°F) and is chemically inert. This means it can easily withstand the harsh conditions inside an autoclave without degrading, warping, or leaching chemicals, ensuring its physical and chemical integrity after every sterilization cycle.

The Critical Role of Sterility

Using a non-sterile tool in a controlled environment is like walking through a cleanroom with muddy boots. It introduces countless variables that can compromise your work.

Preventing Cross-Contamination

The primary goal is to prevent cross-contamination. A shovel used for one substance and not properly sterilized can carry microscopic particles or microbes into the next sample, completely invalidating experimental results or contaminating an entire product batch.

Ensuring Data and Product Integrity

In scientific research, reproducibility is everything. Using a sterile, autoclavable shovel eliminates the tool itself as a variable, ensuring that your results are a true reflection of your experiment. In pharmaceutical or food production, it is a critical step for consumer safety.

Understanding the Trade-offs

While essential, the focus on autoclavability exists within a broader context of material selection and proper procedure.

Not All Plastics Are Equal

Many common plastics, like polyethylene or polypropylene, would melt, soften, or degrade under the extreme conditions of an autoclave. The significance of a PTFE shovel being autoclavable is that this specific, high-performance material was chosen precisely for this capability.

Sterilization Requires Proper Cleaning

Autoclaving sterilizes, but it does not magically remove gross contamination. The shovel must be thoroughly cleaned before being placed in the autoclave. Failure to do so can result in contaminants being "baked on," which can compromise the tool's surface and future sterility.

Durability vs. Function

The robustness that allows PTFE to be autoclaved also makes it a highly durable and chemically resistant material for general use. The feature ensures the tool can be reused reliably for a long time, providing a good return on investment.

Making the Right Choice for Your Application

Selecting a tool always comes down to the requirements of the task.

- If your primary focus is pharmaceutical or biotech manufacturing: An autoclavable shovel is mandatory for ensuring product purity and meeting regulatory compliance like cGMP (Current Good Manufacturing Practice).

- If your primary focus is a quality control or research lab: Using autoclavable tools is fundamental for preventing contamination that could skew data and invalidate hours of work.

- If your primary focus is handling non-sensitive bulk materials: While PTFE's chemical resistance and durability are still beneficial, the specific need for autoclaving may be less critical than factors like cost or size.

Ultimately, choosing an autoclavable PTFE shovel is a deliberate decision to maintain absolute control over the cleanliness and integrity of your work.

Summary Table:

| Feature | Significance |

|---|---|

| Autoclavable | Can be sterilized with steam (121-134°C), killing all microorganisms. |

| Material (PTFE) | Withstands autoclaving without degrading; high melting point (327°C) and chemically inert. |

| Primary Benefit | Prevents cross-contamination, ensuring process integrity and compliance (e.g., cGMP). |

| Key Applications | Pharmaceutical manufacturing, biotechnology, quality control labs, and sensitive R&D. |

Ensure Uncompromising Sterility with KINTEK PTFE Components

In environments where purity is non-negotiable, your tools must be as reliable as your process. The ability to autoclave PTFE shovels and other components is critical for preventing contamination and maintaining integrity in semiconductor, medical, laboratory, and industrial applications.

KINTEK specializes in manufacturing high-precision, autoclavable PTFE components—including seals, liners, labware, and custom fabrications. We understand that your work demands absolute sterility and chemical resistance. Our commitment to precision production ensures that every component, from prototypes to high-volume orders, meets the highest standards for durability and performance.

Ready to enhance your process with tools you can trust? Contact KINTEK today to discuss your specific needs and discover how our PTFE solutions can safeguard your work.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech