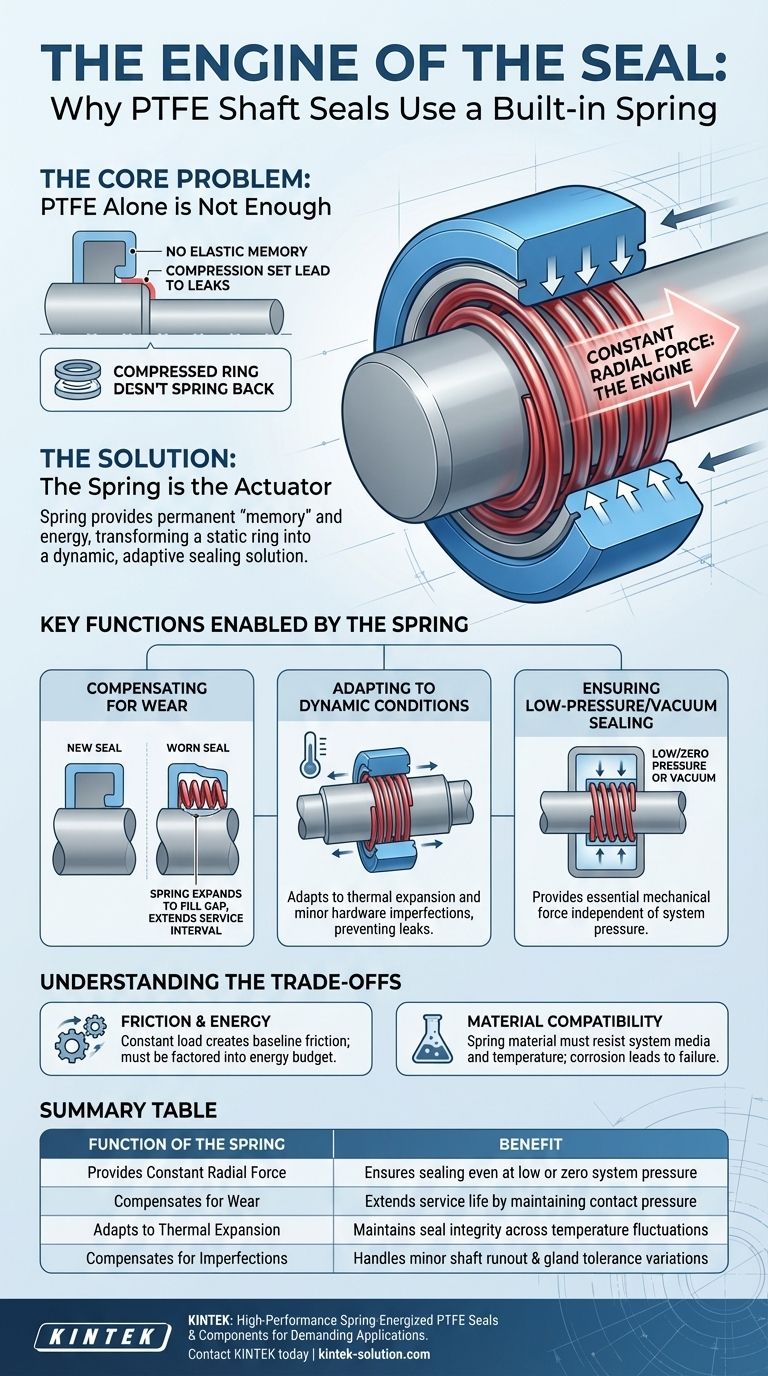

In short, the spring is the engine of the seal. Its primary purpose is to exert a constant, live radial force on the PTFE seal lip, pushing it firmly against the shaft. This mechanical pressure ensures a reliable seal is maintained even when system pressure is low and actively compensates for wear, thermal expansion, and minor hardware imperfections over the seal's lifetime.

The core problem is that PTFE, while an excellent low-friction and chemically resistant material, is not elastic. The internal spring provides the permanent "memory" and energy that PTFE lacks, transforming a static ring into a dynamic, adaptive sealing solution.

The Core Problem: Why PTFE Alone is Not Enough

PTFE is an exceptional material for seals due to its properties, but it has one significant limitation that the spring is designed to solve.

The Inherent Limitation of PTFE

PTFE has very poor elastic memory. When compressed over time, it does not spring back to its original shape, a phenomenon known as compression set.

A simple, un-energized PTFE ring would quickly lose its sealing force as it wears or as temperatures change, leading to inevitable leaks.

The Spring as the Actuator

The spring acts as a constant energy source inside the PTFE jacket. It provides the initial seating load required to create a seal, especially when system pressure is too low or non-existent to "actuate" the seal lip on its own.

This makes spring-energized seals highly effective in a wider range of operating conditions compared to seals relying solely on system pressure.

Key Functions Enabled by the Spring

The spring's constant outward force provides several critical benefits that define the performance and reliability of these advanced seals.

Compensating for Inevitable Wear

As the seal and the shaft rotate against each other, microscopic amounts of material are worn away.

The spring continuously expands to fill this growing gap, maintaining the required contact pressure and ensuring a consistent, leak-free seal throughout its operational life. This dramatically extends the service interval compared to non-energized seals.

Adapting to Dynamic Conditions

Industrial systems are rarely static. Temperature fluctuations cause the shaft and housing materials to expand and contract at different rates.

The spring's flexibility allows it to adapt to these dimensional changes, maintaining a consistent sealing force where a rigid seal would either leak or fail. It also compensates for minor gland tolerance variations and slight shaft runout.

Ensuring Low-Pressure and Vacuum Sealing

Many seal designs rely on the system's fluid or gas pressure to push the seal lip against the shaft. This design fails when pressure is very low, intermittent, or in vacuum applications.

The spring provides the essential mechanical force to create a tight seal in these conditions, making it independent of system pressure for its basic function.

Understanding the Trade-offs

While highly effective, the spring-energized design is not without considerations. Understanding these trade-offs is key to proper application.

Friction and Energy Consumption

The spring's constant radial load creates a baseline level of friction, even in zero-pressure conditions. While PTFE's low friction coefficient mitigates this, a stronger spring for a high-pressure application will inherently generate more drag and wear than a lighter one.

This baseline friction must be factored into the energy budget of the system.

Material Compatibility is Key

The entire seal assembly, including the spring, must be compatible with the system's media and temperature range. The spring is typically made from a corrosion-resistant alloy like stainless steel, but more aggressive chemicals may require exotic materials.

A failure of the spring due to corrosion will lead to a complete failure of the seal.

Making the Right Choice for Your Goal

The purpose of the spring directly translates to which applications benefit most from this seal design.

- If your primary focus is long service life and reliability: The spring's ability to compensate for wear is its most valuable feature, ensuring consistent performance over thousands of hours.

- If your primary focus is sealing under extreme temperature variations: The spring's adaptive force ensures the seal remains engaged as hardware dimensions change, preventing leaks during thermal cycling.

- If your primary focus is performance in low-pressure or vacuum systems: The spring provides the essential, non-negotiable sealing force that the system itself cannot supply.

Ultimately, the spring transforms a passive PTFE ring into an active, responsive sealing system engineered for reliability in demanding conditions.

Summary Table:

| Function of the Spring | Benefit |

|---|---|

| Provides Constant Radial Force | Ensures sealing even at low or zero system pressure |

| Compensates for Wear | Extends service life by maintaining contact pressure |

| Adapts to Thermal Expansion | Maintains seal integrity across temperature fluctuations |

| Compensates for Imperfections | Handles minor shaft runout and gland tolerance variations |

Need a PTFE Seal Engineered for Reliability?

KINTEK specializes in manufacturing high-performance, spring-energized PTFE seals and components for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our seals are designed to provide the precise, constant force required for long-lasting, leak-free performance.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and function for your specific needs.

Contact KINTEK today to discuss your sealing challenge and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers