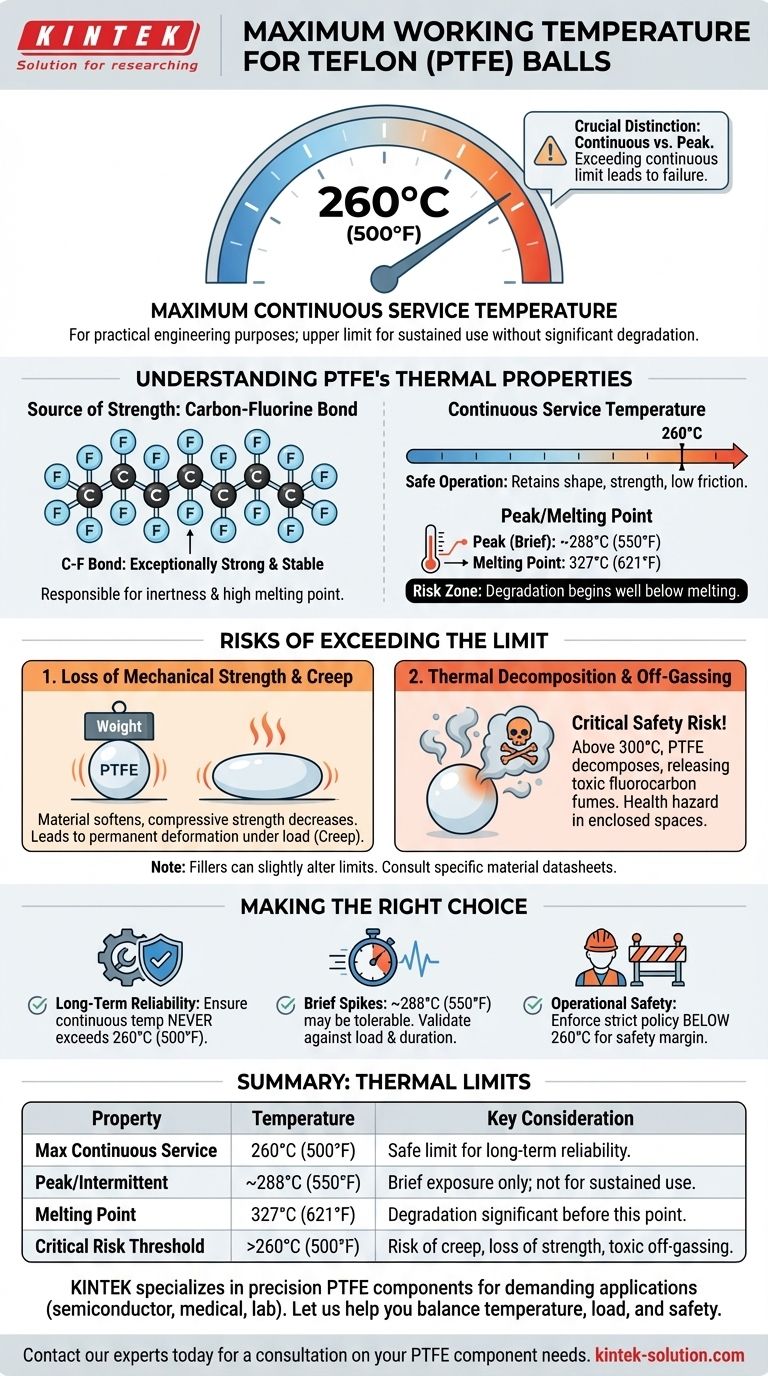

For practical engineering purposes, the maximum continuous working temperature for balls made of pure Polytetrafluoroethylene (PTFE), commonly known as Teflon, is 260°C (500°F). While the material can withstand brief excursions to higher temperatures, this value represents the upper limit for sustained use without significant degradation of its mechanical properties.

The key to using Teflon balls in high-temperature applications is understanding the difference between a "continuous service temperature" and a "peak temperature." Exceeding the continuous limit, even if below the melting point, can lead to component failure and critical safety risks.

Understanding PTFE's Thermal Properties

PTFE's remarkable performance stems from its unique molecular structure. Understanding this provides the context for its operational limits.

The Source of Its Strength: The Carbon-Fluorine Bond

PTFE is a fluoropolymer consisting of a long chain of carbon atoms, with each carbon completely sheathed by fluorine atoms.

The bond between carbon and fluorine is exceptionally strong and stable. This molecular structure is responsible for PTFE's signature properties: extreme chemical inertness and a high melting point.

Continuous Service Temperature

This is the single most important metric for design and reliability. It is the maximum temperature at which the material can operate continuously without a significant loss of its physical properties.

For PTFE, this is consistently rated at 260°C (500°F). Operating at or below this temperature ensures the ball retains its shape, strength, and low-friction characteristics over its expected lifespan.

Peak Temperature and Melting Point

PTFE's melting point is significantly higher, around 327°C (621°F). Some sources cite a peak or intermittent temperature of around 288°C (550°F).

However, these higher values do not represent a safe operating range. They are temperatures the material can survive for very brief periods. Relying on them for system design is a risk, as properties begin to degrade well below the melting point.

Understanding the Trade-offs: The Risks of Exceeding the Limit

Pushing a PTFE ball beyond its continuous service temperature introduces predictable and critical failure modes.

Loss of Mechanical Strength

As the temperature rises above 260°C, PTFE becomes progressively softer. Its compressive strength and wear resistance decrease sharply.

In an application with mechanical load, such as a valve seat or a check ball, this softening leads to creep, where the material slowly and permanently deforms under pressure, causing the component to fail.

Thermal Decomposition and Off-Gassing

This is the most critical safety consideration. When heated above its service limit, PTFE does not just melt; it decomposes.

This process, which accelerates significantly as temperatures approach 300-400°C (572-752°F), releases toxic fluorocarbon fumes. In any application, but especially those in enclosed spaces or involving air handling, operating beyond the service limit poses a serious health hazard.

Impact of Fillers

It is important to note that some PTFE products are made with fillers (such as glass, carbon, or graphite) to enhance specific properties like wear resistance or compressive strength.

These fillers can slightly alter the thermal performance. Always consult the specific datasheet for any filled or blended PTFE material to confirm its unique temperature limits.

Making the Right Choice for Your Application

Use these guidelines to select and apply PTFE balls correctly based on your primary engineering goal.

- If your primary focus is long-term reliability: Design your system to ensure the continuous operating temperature of the PTFE ball never exceeds 260°C (500°F).

- If your application involves brief and infrequent temperature spikes: While brief excursions up to 280°C (550°F) might be tolerable, this must be validated against the specific load, duration, and cycle frequency of your application.

- If your primary focus is operational safety: Enforce a strict policy of operating well below the 260°C (500°F) limit to create a safety margin and prevent any risk of thermal decomposition and hazardous off-gassing.

By respecting these thermal boundaries, you can effectively utilize PTFE's exceptional properties while ensuring the safety and longevity of your design.

Summary Table:

| Thermal Property | Temperature | Key Consideration |

|---|---|---|

| Maximum Continuous Service | 260°C (500°F) | Safe limit for long-term reliability and mechanical integrity. |

| Peak/Intermittent | ~288°C (550°F) | Brief exposure only; not for sustained use. |

| Melting Point | 327°C (621°F) | Material begins to degrade significantly before reaching this point. |

| Critical Risk Threshold | >260°C (500°F) | Risk of creep, loss of strength, and hazardous off-gassing. |

Need high-performance PTFE components that can handle your specific thermal requirements?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom balls—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between temperature, mechanical load, and safety.

Let us help you select the right material or engineer a custom solution that ensures reliability and safety in your application.

Contact our experts today for a consultation on your PTFE component needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of virgin PTFE in rotary shaft seals? Achieve Unmatched Reliability in Demanding Applications

- How does Teflon's performance in extreme temperatures benefit industrial applications? Ensuring Reliable Performance from -200°C to +260°C

- What is a PTFE gasket? The Ultimate Seal for Extreme Chemicals and Temperatures

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- How should designs account for Teflon's high creep rate? Master PTFE Design for Long-Term Reliability

- What temperature range can PTFE coatings withstand? From -260°C to +260°C for Extreme Applications

- What are the benefits of using PTFE flange gaskets? Achieve Superior Sealing in Harsh Industrial Environments

- How do PTFE oil seals and conventional oil seals differ in terms of lubrication requirements? Unlock Superior Performance