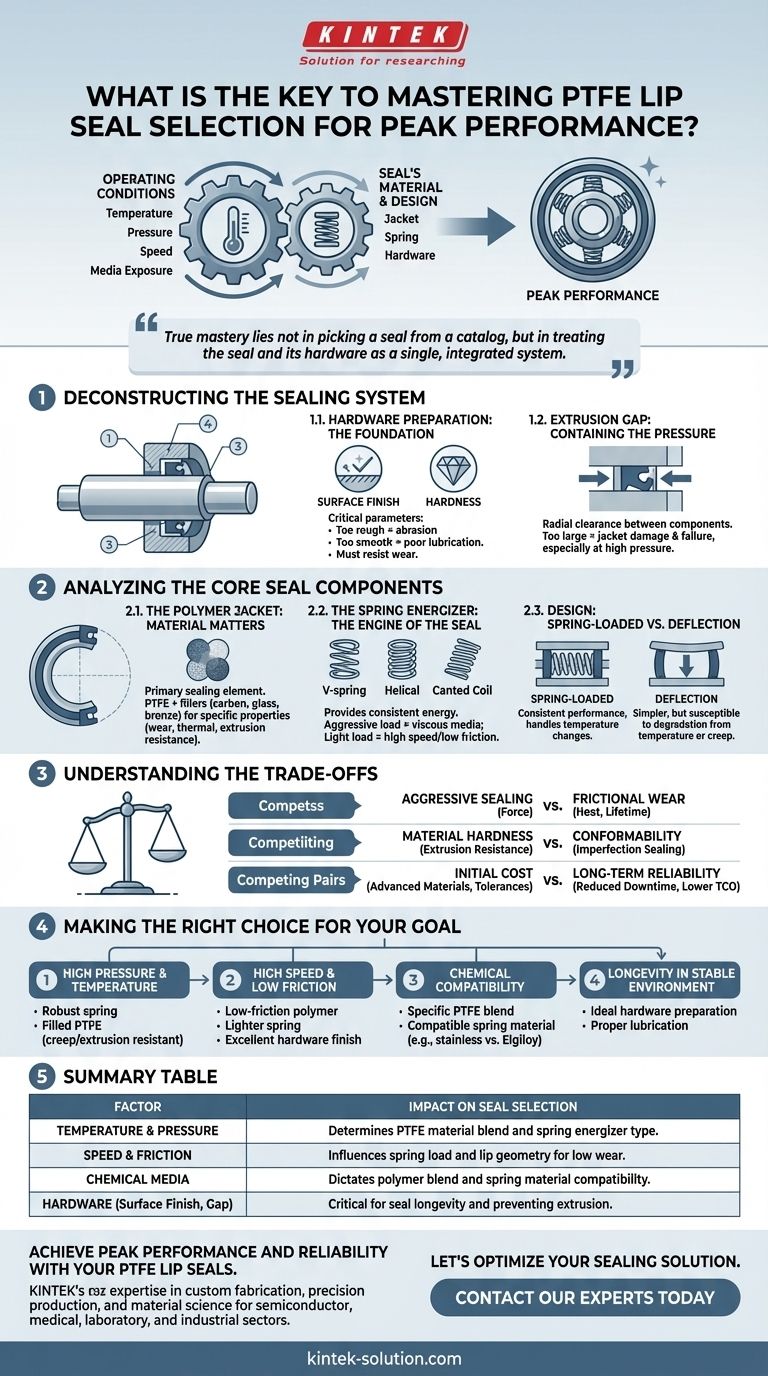

The key to mastering PTFE lip seal selection is understanding it's not about a single component, but the precise interplay between your specific operating conditions and the seal's material and design. To achieve peak performance, you must analyze the temperature, pressure, speed, and media exposure of your application and match them to a seal assembly—jacket, spring, and hardware—that functions as a complete system.

True mastery lies not in picking a seal from a catalog, but in treating the seal and its hardware as a single, integrated system. Every factor—from the mating surface finish to the extrusion gap—directly influences seal performance and longevity.

Deconstructing the Sealing System

A high-performance seal is more than just the polymer ring. Its success is fundamentally tied to the hardware it interacts with. Neglecting the hardware is the most common path to premature seal failure.

Hardware Preparation: The Foundation

The surface finish and hardness of the dynamic sealing surface are not suggestions; they are critical design parameters. An overly rough surface will abrade the PTFE jacket, while a surface that is too smooth can inhibit the formation of a necessary lubricant film.

Similarly, the hardware must be hard enough to resist wear and maintain its finish over the life of the seal.

Extrusion Gap: Containing the Pressure

The extrusion gap, or radial clearance, is the small space between the mating hardware components. Under pressure, the seal is forced into this gap.

If the gap is too large for the operating pressure, the PTFE jacket will be pushed into it, causing damage and eventual failure. This factor is especially critical in high-pressure applications.

Analyzing the Core Seal Components

Once the hardware is defined, you can focus on the specific elements of the seal itself. Each component plays a distinct role and must be matched to the application's demands.

The Polymer Jacket: Material Matters

The PTFE jacket is the primary sealing element. While "PTFE" is the base, various fillers (like carbon, glass, or bronze) are added to enhance specific properties like wear resistance, thermal conductivity, or extrusion resistance.

Choosing the right polymer blend is essential for chemical compatibility and handling the application's temperature and pressure.

The Spring Energizer: The Engine of the Seal

The spring provides the consistent energy needed for the seal lips to maintain contact with the hardware, ensuring a tight seal even at low pressures.

Different spring types (V-spring, helical, canted coil) provide different load characteristics. An aggressive, high-load spring is ideal for viscous media or imperfect hardware, while a light-load spring is better for reducing friction in high-speed applications.

Design: Spring-Loaded vs. Deflection

The choice between a system energized by a spring versus one that relies on material deflection is crucial. Spring-loaded seals offer more consistent performance across a wide range of temperatures and account for wear over time.

Deflection-based seals can be simpler but are more susceptible to performance degradation from temperature changes or material creep.

Understanding the Trade-offs

Selecting a seal is an exercise in balancing competing factors. An ideal seal for one condition is often a poor choice for another.

Aggressive Sealing vs. Frictional Wear

A seal with sharp lip geometry and a high spring load will provide excellent sealing force. However, this aggression increases friction, which generates heat and accelerates wear, potentially shortening the seal's operational life.

Material Hardness vs. Conformability

Harder, filled PTFE grades offer superior resistance to extrusion in high-pressure scenarios. The trade-off is that these materials are less compliant and may struggle to seal effectively on surfaces with minor imperfections.

Initial Cost vs. Long-Term Reliability

Specifying a seal with advanced polymer blends, exotic spring materials, and tight hardware tolerances increases upfront cost. However, this investment often prevents premature failure, reducing costly downtime and equipment damage, leading to a lower total cost of ownership.

Making the Right Choice for Your Goal

To select the optimal seal, begin with your single most critical performance requirement.

- If your primary focus is high pressure and temperature: Prioritize a robust spring energizer and a filled PTFE material that resists creep and extrusion.

- If your primary focus is high speed and low friction: Select a polymer jacket with low-friction fillers and a lighter spring load, paying close attention to hardware surface finish.

- If your primary focus is chemical compatibility: The specific PTFE blend and spring material (e.g., stainless steel vs. Elgiloy) are your most critical decisions.

- If your primary focus is longevity in a stable environment: Focus on achieving the ideal hardware preparation and ensuring proper lubrication to minimize long-term wear.

Ultimately, a successful seal is the result of a deliberate and holistic design process.

Summary Table:

| Factor | Impact on Seal Selection |

|---|---|

| Temperature & Pressure | Determines PTFE material blend and spring energizer type. |

| Speed & Friction | Influences spring load and lip geometry for low wear. |

| Chemical Media | Dictates polymer blend and spring material compatibility. |

| Hardware (Surface Finish, Gap) | Critical for seal longevity and preventing extrusion. |

Achieve peak performance and reliability with your PTFE lip seals.

At KINTEK, we understand that a seal is part of a complete system. Our expertise in custom PTFE component fabrication—from prototypes to high-volume orders—ensures your seals are perfectly matched to your application's unique demands in the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and material science to deliver seals that offer superior chemical resistance, low friction, and long-term durability, reducing downtime and total cost of ownership.

Let's optimize your sealing solution. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability