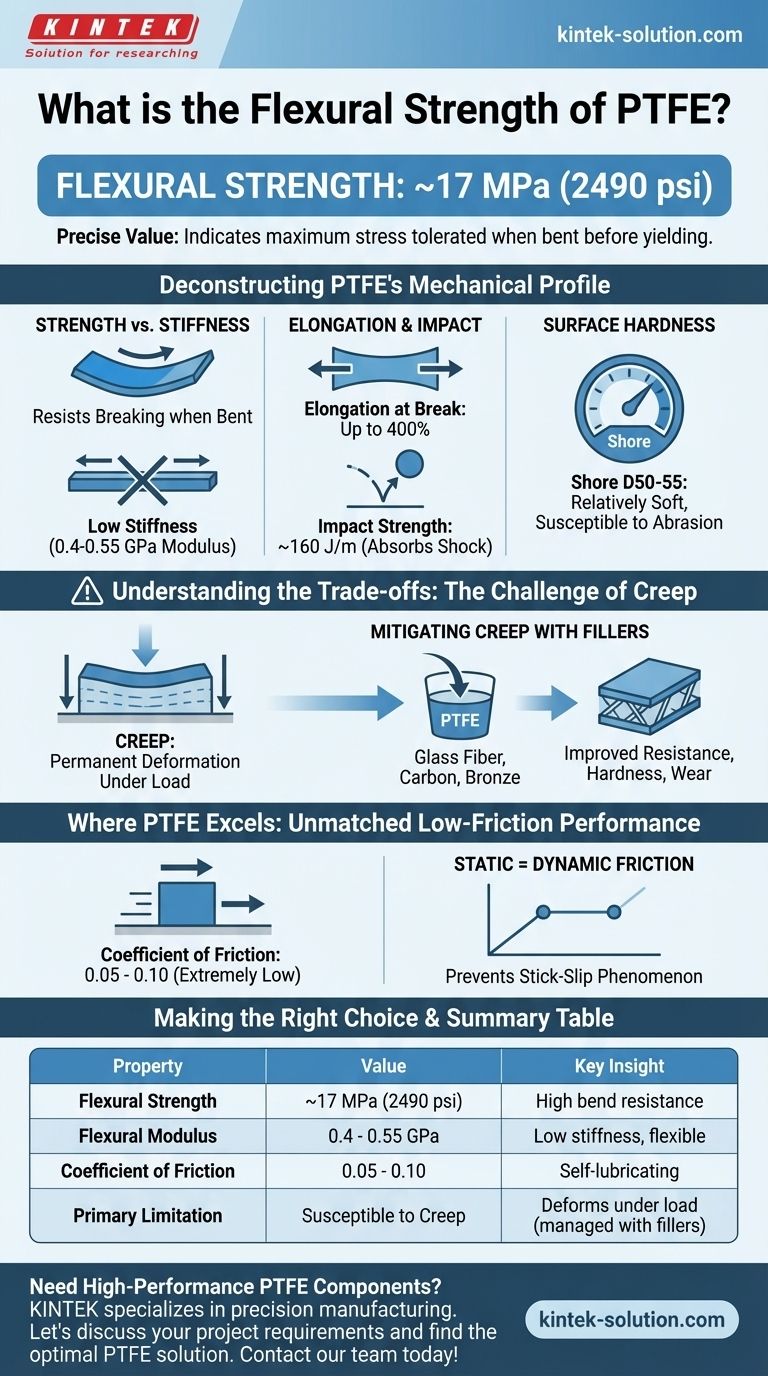

To be precise, the flexural strength of Polytetrafluoroethylene (PTFE) is approximately 17 MPa (2490 psi). This value indicates the maximum stress the material can withstand in a bending scenario before it yields or breaks. However, this single number only tells part of the story, as PTFE's primary mechanical advantage is its exceptional flexibility and durability, not its rigidity.

The core takeaway is that while PTFE has a high flexural strength, meaning it can bend significantly without breaking, this property is coupled with low stiffness and a tendency to deform under sustained pressure. Therefore, its suitability depends entirely on whether your application requires flexibility and low friction or rigid, load-bearing strength.

Deconstructing PTFE's Mechanical Profile

Understanding PTFE requires looking beyond a single data point. Its mechanical behavior is a unique combination of toughness, softness, and unparalleled lubricity.

Flexural Strength vs. Stiffness

Flexural strength measures the ability to resist breaking when bent. PTFE excels here.

In contrast, stiffness (or flexural modulus) measures the ability to resist bending in the first place. PTFE is not a stiff material; its Young's Modulus is quite low, ranging from 0.4 to 0.55 GPa. This is why it feels flexible and pliable rather than rigid.

The Role of Elongation and Impact Strength

PTFE's high flexural strength is a direct result of its ductility. With an elongation at break of up to 400%, it can stretch and deform significantly before failing.

This is complemented by good impact strength (around 160 J/m). It can absorb sudden shocks and impacts without shattering, unlike more brittle plastics.

A Relatively Soft Material

Despite its toughness, PTFE has a low surface hardness of D50-55 on the Shore D scale. This means it is susceptible to scratching and abrasion. While durable in many contexts, it is not considered a hard-wearing material in its unfilled state.

Understanding the Trade-offs: The Challenge of Creep

No material is perfect, and PTFE's primary mechanical limitation is its susceptibility to permanent deformation under load, a phenomenon known as creep or "cold flow."

What is Creep?

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. For PTFE, this means a component under constant compression, like a seal or gasket, will gradually deform over time.

When Creep Becomes a Problem

This deformation can lead to failure in applications where tight tolerances are critical. For example, a PTFE seal under constant pressure may eventually deform enough to cause a leak. Similarly, a bearing under a continuous load can lose its shape, compromising performance.

Mitigating Creep with Fillers

This weakness can be effectively managed by using filled grades of PTFE. Adding fillers like glass fiber, carbon, or bronze dramatically improves creep resistance, hardness, and wear resistance, making the material suitable for more demanding mechanical applications.

Where PTFE Excels: Unmatched Low-Friction Performance

The defining characteristic of PTFE is its extremely low coefficient of friction, which is often the primary reason for its selection.

An Exceptionally Low Coefficient of Friction

With a coefficient of friction between 0.05 and 0.10, PTFE is one of the most slippery solid materials known. This gives it self-lubricating properties that are essential for high-performance bearings, seals, and non-stick coatings.

The Advantage of Consistent Friction

Crucially, the static (starting) and dynamic (moving) coefficients of friction are nearly identical. This prevents the "stick-slip" phenomenon common in other materials, ensuring a smooth transition from a standstill to motion without jerking.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary goal.

- If your primary focus is dynamic seals or low-friction bearings: PTFE's lubricity is ideal, but consider filled grades to manage wear and creep under sustained loads.

- If your primary focus is a structural, load-bearing component: Unfilled PTFE is likely unsuitable due to its low stiffness and tendency to creep under pressure.

- If your primary focus is flexibility and chemical resistance: PTFE's ability to bend without fracturing, combined with its chemical inertness, makes it an excellent choice for flexible tubing, gaskets, or linings.

Ultimately, you should select PTFE not for its absolute strength, but for its unique synthesis of flexibility, chemical resistance, and unparalleled surface lubricity.

Summary Table:

| Property | Value | Key Insight |

|---|---|---|

| Flexural Strength | ~17 MPa (2490 psi) | High resistance to breaking when bent. |

| Flexural Modulus (Stiffness) | 0.4 - 0.55 GPa | Low stiffness; material is flexible and pliable. |

| Coefficient of Friction | 0.05 - 0.10 | Extremely low, providing self-lubricating properties. |

| Primary Limitation | Susceptible to Creep | Can deform under sustained load (managed with fillers). |

Need High-Performance PTFE Components?

PTFE's unique combination of flexibility, chemical inertness, and low friction makes it ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of PTFE components—from custom seals, liners, and labware to complex fabricated parts. We help you leverage PTFE's advantages while mitigating its limitations through:

- Expert Material Selection: Advising on unfilled or filled grades (e.g., with glass, carbon, bronze) to enhance creep resistance and wear for your specific application.

- Precision Production & Custom Fabrication: Delivering high-quality parts from prototypes to high-volume orders.

Let's discuss your project requirements and find the optimal PTFE solution. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications