Crucially, there is no fixed service life for an expanded PTFE (ePTFE) gasket that can be measured in months or years. Instead, its lifespan is determined entirely by its ability to operate within its specified chemical, thermal, and mechanical limits. As long as these conditions are met, ePTFE is a non-aging material that provides an exceptionally long and stable service life.

The longevity of an expanded PTFE gasket is not a function of time, but of its environment. Its remarkable resistance to chemical degradation, temperature extremes, and mechanical creep means it will not degrade on its own, making its service life indefinite when used within its operational boundaries.

The Core Properties Defining ePTFE Longevity

The reason we cannot assign a simple "expiration date" to an ePTFE gasket is due to its unique material composition and structure. Several key properties work together to prevent the common modes of failure that shorten the life of other gasket materials.

Unmatched Chemical Inertness

An ePTFE gasket is a synthetic fluoropolymer composed entirely of carbon and fluorine. This stable molecular structure makes it innately hydrophobic and inert.

It is unaffected by the vast majority of corrosive liquids, vapors, and gases. This chemical resistance prevents the gasket from swelling, dissolving, or becoming brittle, which are primary causes of seal failure in aggressive environments.

Extreme Temperature Tolerance

Expanded PTFE functions effectively across an exceptionally wide temperature range, typically from cryogenic temperatures (-200°C / -328°F) up to +260°C (+500°F).

This stability means the gasket maintains its sealing integrity without becoming brittle at low temperatures or degrading at high temperatures, ensuring reliable performance during significant thermal cycling.

Superior Mechanical Stability (Low Creep)

A critical factor for long-term sealing is a material's resistance to creep relaxation. This is the tendency for a gasket to deform or "flatten" over time under the pressure of a flange, causing a loss of sealing force.

Expanded PTFE exhibits very low creep relaxation. It maintains its shape and recovery properties, ensuring it continues to exert sealing pressure long after installation, minimizing the need for re-torquing bolts.

Intrinsic Resistance to Aging

Unlike many elastomers and organic materials, ePTFE is unaffected by UV radiation, oxidation, or general environmental exposure.

This "non-aging" characteristic means the material properties do not degrade over time when left in storage or installed in an application exposed to the elements.

Understanding the Trade-offs and Failure Points

While exceptionally durable, an ePTFE gasket's longevity is conditional. Understanding its limitations is key to preventing premature failure and ensuring you have chosen the right material for the job.

Exceeding Operational Boundaries

The single greatest cause of failure is using the gasket outside its specified limits. If the application temperature exceeds +260°C (+500°F), the material will begin to degrade rapidly. Likewise, extreme pressures beyond the gasket's rating can cause mechanical failure.

Specific Chemical Incompatibilities

While resistant to almost all chemicals, ePTFE can be attacked by a very small number of substances. These include molten alkali metals (like sodium) and some rare, highly reactive fluorinating agents. Always confirm chemical compatibility for your specific application.

The Impact of Installation

Expanded PTFE is soft and highly compressible, making it excellent for sealing irregular or damaged flange surfaces. However, proper installation is still paramount.

Over-compression can crush the material's porous structure and damage its sealing capabilities, while under-compression will fail to create an effective initial seal. Following the manufacturer's torque specifications is essential for achieving maximum service life.

Making the Right Choice for Your Goal

Select your gasket material based on the primary demands of the application. Expanded PTFE excels where longevity under harsh conditions is the goal.

- If your primary focus is reliability in corrosive environments: Its chemical inertness makes ePTFE the default choice for aggressive media where other materials would quickly fail.

- If your primary focus is a long-term, low-maintenance seal: The material's resistance to creep and aging ensures it maintains sealing force over extended periods without frequent intervention.

- If your primary focus is performance across wide temperature shifts: ePTFE's stability from cryogenic lows to high heat guarantees a consistent and reliable seal during demanding thermal cycling.

Ultimately, the service life of an expanded PTFE gasket is a direct result of its operational environment; when used correctly, it is one of the most durable and reliable sealing solutions available.

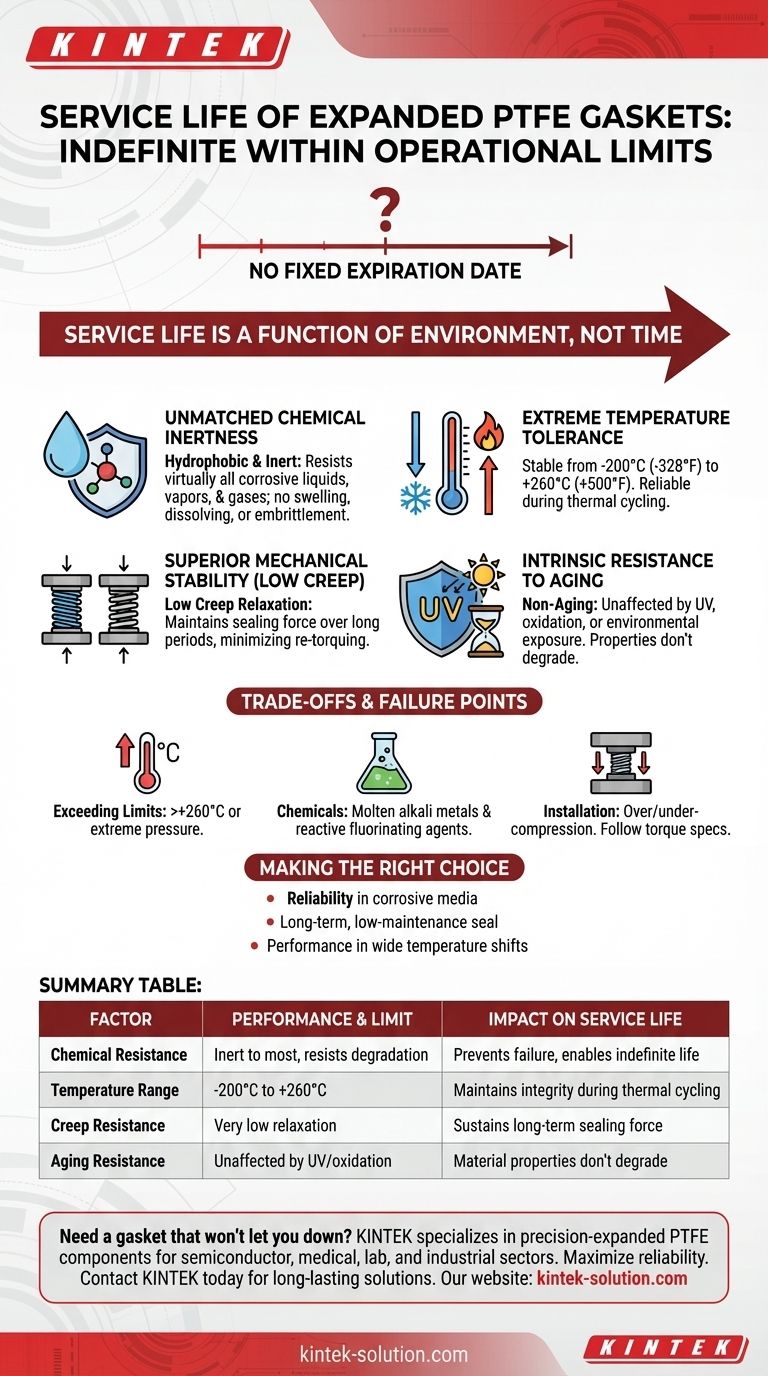

Summary Table:

| Factor | ePTFE Gasket Performance & Limit | Impact on Service Life |

|---|---|---|

| Chemical Resistance | Inert to most chemicals; resists swelling & degradation. | Prevents chemical failure, enabling indefinite life. |

| Temperature Range | Stable from -200°C to +260°C (-328°F to +500°F). | Maintains integrity during extreme thermal cycling. |

| Creep Resistance | Very low creep relaxation under compression. | Sustains sealing force long-term, minimizing maintenance. |

| Aging Resistance | Unaffected by UV, oxidation, or environmental exposure. | Material properties do not degrade over time. |

Need a gasket that won't let you down?

Your application demands a seal that lasts. KINTEK specializes in manufacturing precision-expanded PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure our ePTFE products deliver the exceptional chemical inertness, thermal stability, and mechanical durability detailed in this article. Whether you need a prototype or a high-volume order, our custom fabrication expertise guarantees a perfect fit for your specific operational boundaries.

Maximize your system's reliability and minimize downtime. Contact KINTEK today to discuss your project and receive a quote for long-lasting PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability