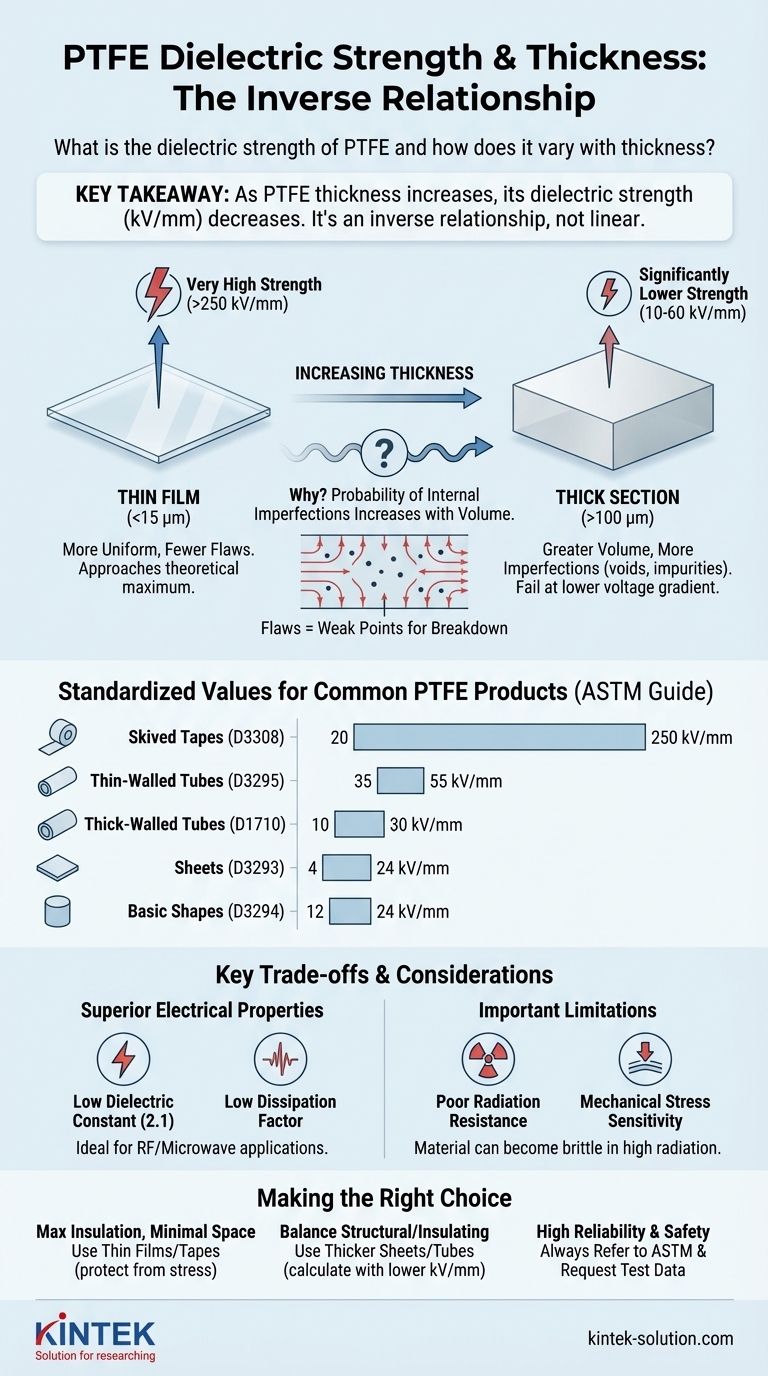

For practical purposes, the dielectric strength of Polytetrafluoroethylene (PTFE) is not a single value but is inversely dependent on the material's thickness. While extremely thin PTFE films can exhibit a very high dielectric strength, sometimes exceeding 250 kV/mm, thicker sections of the material will have a significantly lower value, often in the range of 10 to 60 kV/mm. This is a critical factor for any engineering or design application.

The most important takeaway is that as PTFE thickness increases, its measured dielectric strength (in kV/mm) decreases. Simply making an insulator thicker does not scale its voltage-withstanding capability linearly, because the probability of internal imperfections increases with volume.

The Inverse Relationship: Thickness vs. Strength

To properly apply PTFE as an electrical insulator, it's essential to understand why its dielectric strength changes so dramatically with its physical dimensions.

What is Dielectric Strength?

Dielectric strength is the maximum electric field an insulating material can withstand without "breaking down"—a point where it fails and becomes electrically conductive. Think of it as the electrical breaking point of an insulator.

This property is measured in kilovolts per millimeter (kV/mm) or volts per mil. It defines how much voltage is required to arc across a 1 mm thickness of the material.

The Impact of Material Flaws

The inverse relationship between thickness and dielectric strength is not unique to PTFE, but it is pronounced. This phenomenon occurs because a thicker piece of material has a statistically higher chance of containing microscopic voids, impurities, or structural imperfections.

These tiny flaws act as weak points within the insulator. Under a high electric field, they become concentration points where the breakdown process can begin, leading to a failure of the entire insulating barrier at a lower overall voltage gradient.

Thin Films vs. Thick Sections

Thin films (often under 15 microns) are more structurally uniform and have a much lower probability of containing a critical flaw. This allows them to approach their theoretical maximum insulating capability, with dielectric strengths that can exceed 250 kV/mm.

Thicker sections (100 microns or more) have a much greater internal volume. The increased likelihood of imperfections means they will break down at a lower average electric field. For these materials, dielectric strengths as low as 20 kV/mm are common.

Standardized Values for Common PTFE Products

Theoretical maximums are useful, but for real-world applications, engineers rely on tested values established by standards organizations like ASTM International. These provide a more realistic expectation for commercially available PTFE forms.

ASTM Standards as a Guide

Different manufacturing processes result in different material densities and levels of internal consistency. Therefore, the expected dielectric strength varies by the product type.

Dielectric Strength by Product Form

- Skived Tapes (ASTM D3308): This form shows the widest range, from 20 to 250 kV/mm, reflecting the variety of tape thicknesses available.

- Thin-Walled Tubes (ASTM D3295): Typically exhibit high strength, often in the 35 to 55 kV/mm range.

- Thick-Walled Tubes (ASTM D1710): As thickness increases, the rating drops to 10 to 30 kV/mm.

- Sheets (ASTM D3293): Generally fall within the 4 to 24 kV/mm range.

- Basic Shapes (ASTM D3294): Molded shapes like rods and blocks have a similar range of 12 to 24 kV/mm.

Key Trade-offs and Considerations

While dielectric strength is a critical parameter, it must be considered alongside PTFE's other properties to determine if it is right for your application.

Superior Electrical Properties

PTFE is an outstanding insulator for reasons beyond just dielectric strength. It maintains a very low dielectric constant of 2.1 and a low dissipation factor across a wide range of frequencies, making it ideal for high-frequency applications like RF and microwave circuits.

Important Material Limitations

No material is perfect. A key limitation of PTFE is its poor resistance to radiation. In high-radiation environments, the polymer chains can be damaged, causing the material to become brittle and lose its desirable properties.

Making the Right Choice for Your Application

Selecting the correct PTFE thickness requires balancing the need for electrical insulation with mechanical and spatial constraints.

- If your primary focus is maximum insulation in minimal space: Use thin PTFE films or skived tapes, but ensure your design protects them from mechanical stress and abrasion.

- If your primary focus is a balance of structural and insulating properties: Use thicker sheets or tubes, but perform breakdown voltage calculations using the lower, more conservative kV/mm rating appropriate for that thickness.

- If your primary focus is high reliability and safety: Always refer to the specific ASTM standard for your chosen product form and request test data from your material supplier for the exact lot you are using.

Ultimately, understanding that dielectric strength in PTFE is a function of thickness is the key to designing robust and reliable electrical systems.

Summary Table:

| PTFE Product Form (ASTM Standard) | Typical Dielectric Strength Range (kV/mm) |

|---|---|

| Skived Tapes (D3308) | 20 - 250 |

| Thin-Walled Tubes (D3295) | 35 - 55 |

| Thick-Walled Tubes (D1710) | 10 - 30 |

| Sheets (D3293) | 4 - 24 |

| Basic Shapes (D3294) | 12 - 24 |

Need high-performance PTFE components with guaranteed dielectric properties?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, and laboratory industries. We understand that your application's success depends on reliable material performance. Our expertise ensures your PTFE parts are fabricated to the exact specifications required for your voltage and environmental conditions, from prototypes to high-volume production.

Contact our engineering team today to discuss your project's requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech