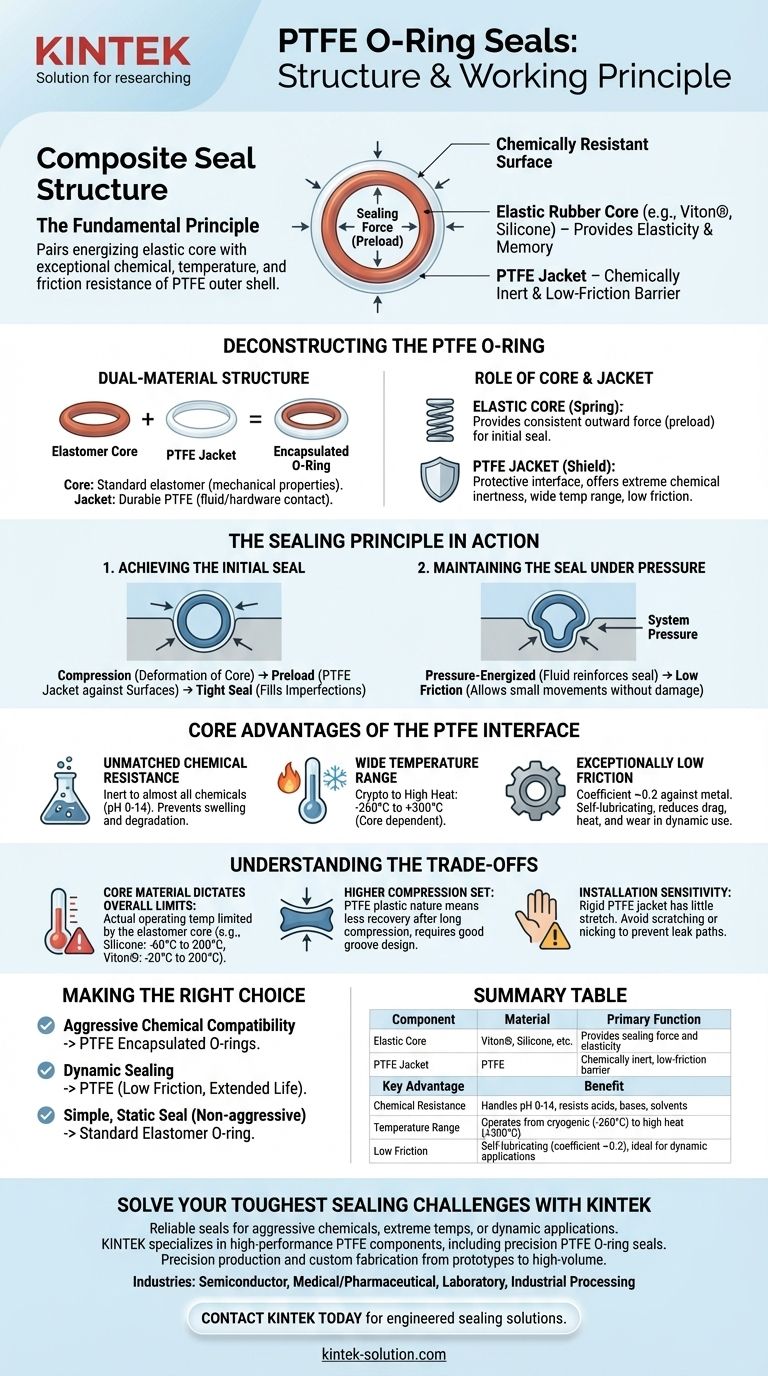

At its core, a PTFE O-ring is a composite seal combining two materials to achieve performance that neither could alone. Its structure typically consists of an elastic rubber core, like Viton® or silicone, encapsulated in a seamless jacket of Polytetrafluoroethylene (PTFE). This design leverages the flexibility of the rubber core to create a reliable sealing force while using the PTFE jacket as a robust barrier against harsh environments.

The fundamental principle of a PTFE O-ring is to pair the energizing, elastic properties of a rubber core with the exceptional chemical, temperature, and friction resistance of a PTFE outer shell, creating a high-performance seal for demanding applications.

Deconstructing the PTFE O-ring

A standard O-ring relies on a single material (an elastomer) for both its elasticity and its chemical resistance. A PTFE O-ring separates these functions into a more effective, two-part system.

The Dual-Material Structure

The most common configuration is an encapsulated O-ring. This features an inner core made from a standard elastomer chosen for its mechanical properties.

This core is then seamlessly enclosed within a thin but durable PTFE jacket. This jacket becomes the only part of the seal that makes contact with the system fluid and hardware.

The Role of the Elastic Core

The inner rubber core acts as the "spring" of the seal. Its primary job is to provide the elasticity and memory needed to conform to the sealing surfaces.

When compressed during installation, this core provides the consistent outward force, or preload, that is essential for creating the initial, positive seal.

The Function of the PTFE Jacket

The PTFE jacket is the high-performance interface. It provides the characteristics that standard elastomers lack, acting as a protective shield for the vulnerable core.

This outer layer delivers extreme chemical inertness, a wide operating temperature range, and a very low coefficient of friction.

The Sealing Principle in Action

The sealing mechanism is a two-stage process that leverages both the initial compression and the subsequent system pressure to maintain a leak-proof barrier.

Achieving the Initial Seal

Upon installation in a groove, the O-ring is squeezed. This compression deforms the elastic core, which pushes the PTFE jacket firmly against the mating surfaces.

This initial preload fills microscopic imperfections in the hardware, forming a tight seal even when the system is not pressurized.

Maintaining the Seal Under Pressure

When the system is pressurized, that pressure finds its way to the O-ring. The fluid pushes on the seal, forcing it more tightly against the downstream side of the groove.

This pressure-energized action reinforces the seal, with the low-friction PTFE jacket allowing for small movements without damage or excessive wear, especially in dynamic applications.

Core Advantages of the PTFE Interface

The "King of Plastics," PTFE imparts several critical performance advantages that make these seals ideal for challenging industrial environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, solvents, and fuels. It can reliably handle fluids with a pH range from 0 to 14.

This prevents the chemical swelling, degradation, and failure common with standard rubber seals in corrosive applications.

Wide Temperature Range

Pure PTFE can withstand an exceptionally broad temperature range, from cryogenic conditions (-260°C) up to very high heat (+300°C).

This thermal stability far exceeds that of nearly all elastomers.

Exceptionally Low Friction

With a coefficient of friction around 0.2 against metal, PTFE provides a self-lubricating surface.

This is a major advantage in reciprocating or rotating applications, as it reduces drag, heat generation, and wear on both the seal and the hardware.

Understanding the Trade-offs

While powerful, the composite nature of PTFE O-rings introduces specific limitations that must be understood for successful application.

The Core Material Dictates Overall Limits

The impressive temperature range of PTFE is only one part of the equation. The seal's actual operating temperature is limited by its elastomer core.

A silicone core offers a wide temperature range (approx. -60°C to 200°C) but has poor gas permeability. A Viton® (FKM) core offers excellent chemical resistance but within a narrower temperature band (approx. -20°C to 200°C). The core is the weak link for temperature and pressure.

Higher Compression Set

PTFE is a plastic, not a true rubber. It is less "bouncy" and does not recover its original shape as well as an elastomer after being compressed for a long time.

This means PTFE O-rings have a higher compression set. They are less forgiving of poorly designed grooves or repeated assembly and disassembly cycles.

Installation Sensitivity

The PTFE jacket is relatively rigid and has very little stretch compared to a standard O-ring.

This requires extra care during installation to avoid scratching, nicking, or creasing the jacket, as any damage can create a potential leak path.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to the primary challenge of your system.

- If your primary focus is aggressive chemical compatibility: PTFE encapsulated O-rings are the definitive choice where standard elastomers would chemically degrade and fail.

- If your primary focus is dynamic sealing: The low-friction, self-lubricating surface of PTFE reduces wear and heat, significantly extending seal life in reciprocating or rotating parts.

- If your primary focus is a simple, static seal in a non-aggressive environment: A standard, single-material elastomer O-ring is often a more flexible and cost-effective solution.

Ultimately, choosing a PTFE O-ring is a strategic decision to solve specific engineering challenges that commodity seals cannot address.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Elastic Core | Viton®, Silicone, etc. | Provides the sealing force and elasticity. |

| PTFE Jacket | Polytetrafluoroethylene (PTFE) | Acts as a chemically inert, low-friction barrier. |

| Key Advantage | Benefit | |

| Chemical Resistance | Handles pH 0-14, resists acids, bases, and solvents. | |

| Temperature Range | Operates from cryogenic (-260°C) to high heat (+300°C). | |

| Low Friction | Self-lubricating (coefficient ~0.2), ideal for dynamic applications. |

Solve Your Toughest Sealing Challenges with KINTEK

Do you need a reliable seal for aggressive chemicals, extreme temperatures, or demanding dynamic applications? Standard elastomer O-rings may not be enough.

KINTEK specializes in manufacturing high-performance PTFE components, including precision PTFE O-ring seals. We understand that every application is unique. That’s why we prioritize precision production and offer custom fabrication—from initial prototypes to high-volume production runs—to meet your exact specifications.

Our PTFE seals are trusted in the most demanding industries, including:

- Semiconductor manufacturing

- Medical and pharmaceutical equipment

- Laboratory and analytical instrumentation

- Industrial processing

Let us help you enhance your system's reliability and longevity.

Contact KINTEK today to discuss your specific requirements and get a quote for a sealing solution engineered for performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments