PTFE, or Polytetrafluoroethylene, is a high-performance synthetic fluoropolymer prized in industry for its unique combination of properties. It is predominantly used in applications requiring extreme chemical resistance, very low friction, and stability at high temperatures, making it an essential material for harsh operating environments.

The core value of PTFE in an industrial context is not a single feature, but its rare ability to solve three critical challenges at once: it resists chemical attack, reduces mechanical friction, and endures high heat, making it a go-to problem-solver for the most demanding applications.

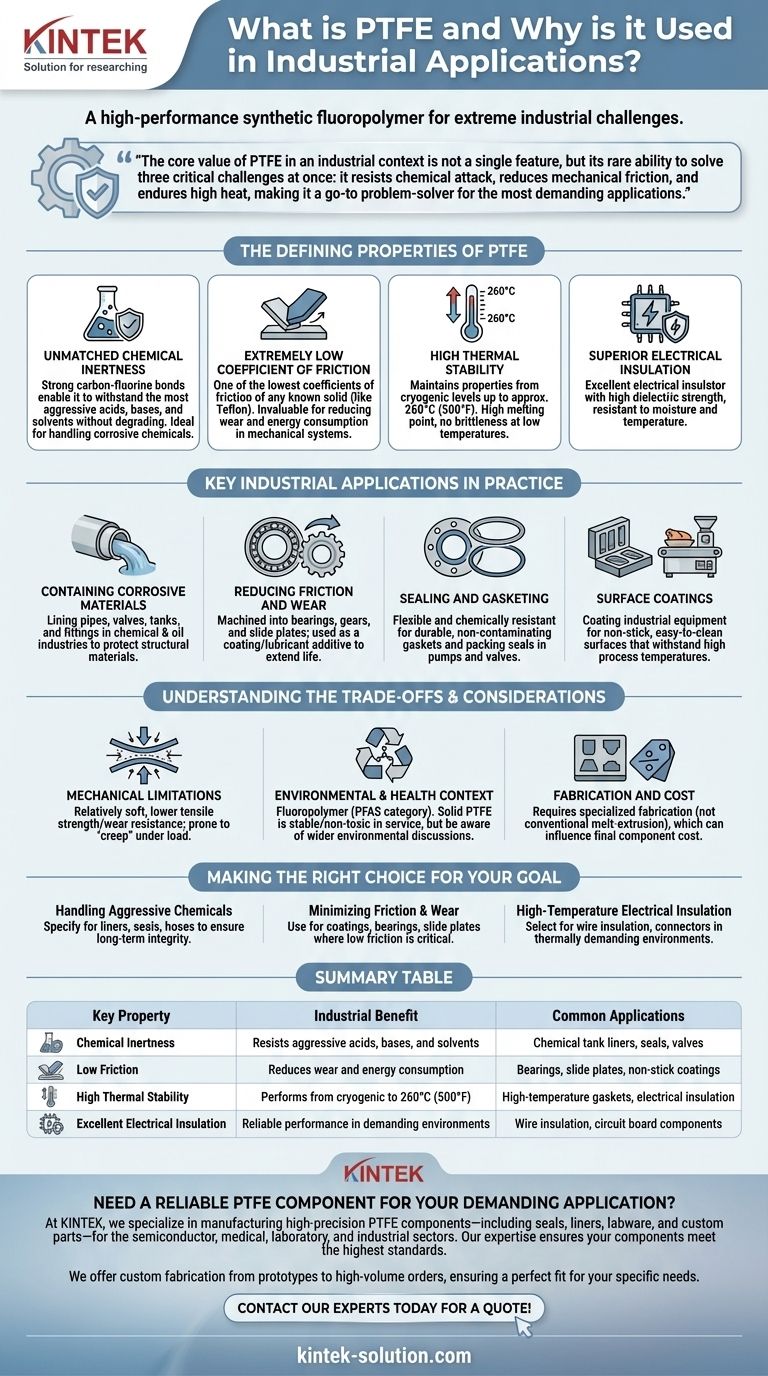

The Defining Properties of PTFE

To understand why PTFE is so widely specified, we must first examine its fundamental characteristics. These properties are a direct result of its molecular structure, which consists of a carbon chain fully shielded by fluorine atoms.

Unmatched Chemical Inertness

The carbon-fluorine bond is exceptionally strong, making the PTFE molecule highly stable and non-reactive. This means it can withstand exposure to the most aggressive acids, bases, and solvents without degrading.

This chemical inertness is why PTFE is the material of choice for handling and storing corrosive chemicals.

An Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. Its surface is incredibly slippery, a property often recognized by its most famous brand name, Teflon.

This "non-stick" characteristic is invaluable for reducing wear and energy consumption in mechanical systems.

High Thermal Stability

PTFE maintains its properties over a wide temperature range, from cryogenic levels up to approximately 260°C (500°F). It has a high melting point and does not become brittle at low temperatures.

This allows it to perform reliably in environments where other polymers would fail due to thermal stress.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. Its resistance to moisture and temperature further enhances its reliability in electrical and electronic applications.

Key Industrial Applications in Practice

The unique combination of PTFE's properties translates directly into solutions for common and difficult industrial challenges across numerous sectors.

Containing Corrosive Materials

The most common application is lining pipes, valves, tanks, and fittings in the chemical processing and oil & gas industries. Using a PTFE liner protects less-resistant structural materials (like steel) from corrosion.

Reducing Friction and Wear

Due to its low friction, PTFE is machined into components like bearings, gears, and slide plates. It is also used as a coating or lubricant additive to ensure smooth operation and extend the life of moving parts.

Sealing and Gasketing

PTFE's flexibility and chemical resistance make it an ideal material for gaskets and packing seals. It creates a durable, non-contaminating seal in pumps and valves, even when handling oxidizing media or harsh chemicals.

Surface Coatings

Industrial equipment, from food processing machinery to manufacturing molds, is often coated with PTFE. This provides a non-stick, easy-to-clean surface that can withstand high process temperatures.

Understanding the Trade-offs and Considerations

While incredibly versatile, PTFE is not the solution for every problem. An objective assessment requires understanding its limitations.

Mechanical Limitations

PTFE is a relatively soft material with lower tensile strength and wear resistance compared to many engineering plastics. It can be prone to "creep," or deformation under a sustained load, which must be accounted for in structural designs.

Environmental and Health Context

PTFE is a type of fluoropolymer, a category of chemicals within the broader group known as PFAS. While solid PTFE is stable and non-toxic under its normal service temperatures, it is important to be aware of the wider environmental and regulatory discussions surrounding the PFAS class of chemicals.

Fabrication and Cost

PTFE's high melting point means it cannot be processed with conventional melt-extrusion or molding techniques used for other thermoplastics. This requires specialized fabrication methods, which can influence the final component cost.

Making the Right Choice for Your Goal

Selecting PTFE is a decision driven by the specific demands of your operating environment. Use it where its unique strengths provide a clear advantage.

- If your primary focus is handling aggressive chemicals: Specify PTFE for liners, seals, hoses, and fluid-handling components to ensure long-term integrity and prevent corrosion.

- If your primary focus is minimizing friction and wear: Use PTFE for coatings, bearings, or slide plates in mechanical systems where low friction and self-lubrication are critical.

- If your primary focus is high-temperature electrical insulation: Select PTFE for wire insulation, connectors, and circuit board components that must perform reliably in thermally demanding environments.

Ultimately, PTFE's legacy is that of a specialty material engineered to perform where standard polymers simply cannot survive.

Summary Table:

| Key Property | Industrial Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents | Chemical tank liners, seals, valves |

| Low Friction | Reduces wear and energy consumption | Bearings, slide plates, non-stick coatings |

| High Thermal Stability | Performs from cryogenic to 260°C (500°F) | High-temperature gaskets, electrical insulation |

| Excellent Electrical Insulation | Reliable performance in demanding environments | Wire insulation, circuit board components |

Need a reliable PTFE component for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the highest standards for chemical resistance, thermal stability, and performance.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific needs.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications