Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer composed of carbon and fluorine, famously known for its non-stick properties. This remarkable material was discovered by accident on April 6, 1938, by chemist Dr. Roy J. Plunkett while he was researching new refrigerants.

The accidental discovery of PTFE in 1938 was not merely the creation of a new substance; it introduced a revolutionary class of material defined by its extreme chemical inertness, high-temperature resistance, and incredibly low friction.

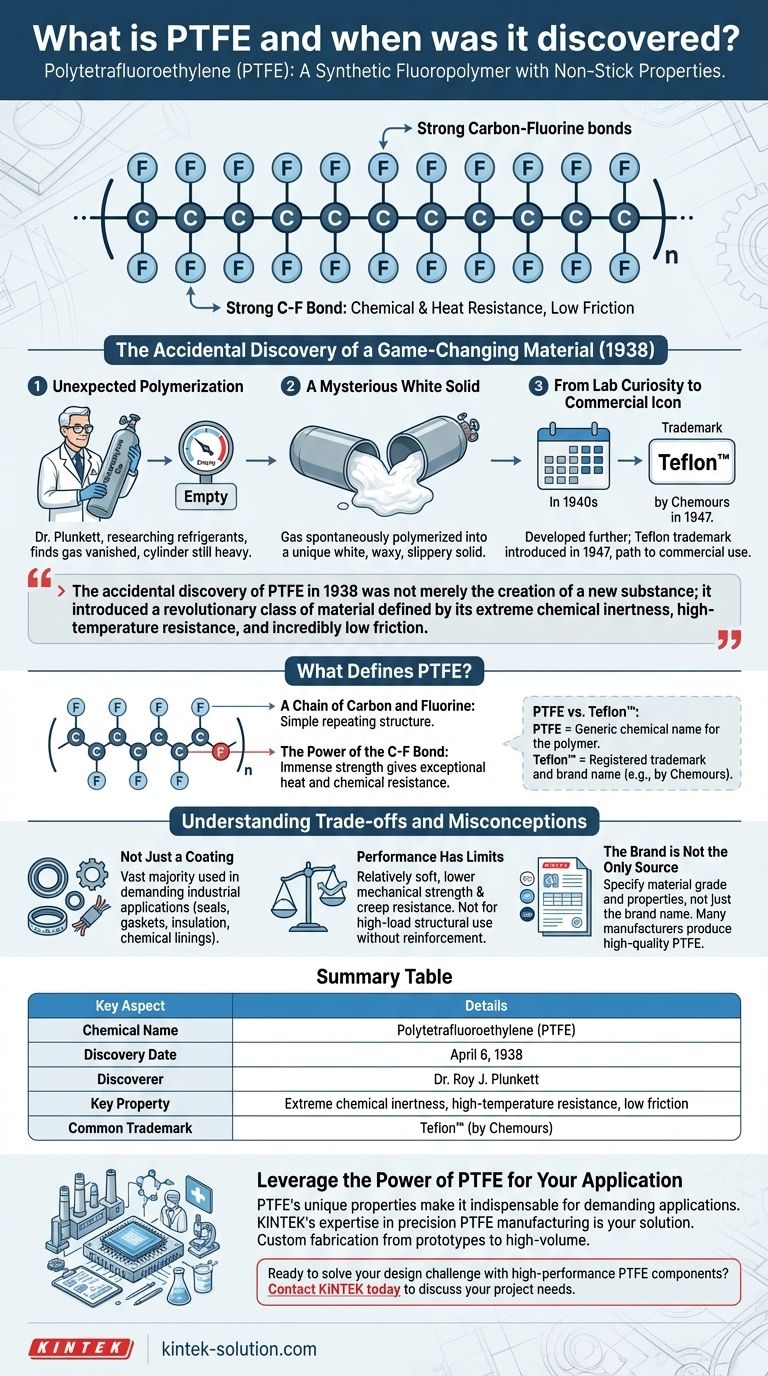

The Accidental Discovery of a Game-Changing Material

The story of PTFE is a classic example of scientific serendipity. The discovery was not the result of a targeted search but of a fortunate accident that was astutely observed.

The Unexpected Polymerization

Dr. Plunkett was working with a compressed, frozen sample of tetrafluoroethylene gas for refrigerant development. When he later inspected the cylinder, he found that the gas had vanished, despite the cylinder's weight indicating it was still full.

A Mysterious White Solid

After cutting open the cylinder, Plunkett discovered that the gas had spontaneously polymerized into a white, waxy, and remarkably slippery solid. This new substance was unlike anything he had seen before.

From Lab Curiosity to Commercial Icon

The material's unique properties were immediately recognized as valuable. It was developed further during the 1940s, and the trademark Teflon was introduced by Chemours (then part of DuPont) in 1947, solidifying its path to widespread commercial use.

What Defines PTFE?

PTFE's properties are a direct result of its simple but powerful molecular structure. Understanding this structure is key to understanding its capabilities.

A Chain of Carbon and Fluorine

At its core, PTFE is a very long chain of carbon atoms, where each carbon atom is bonded to two fluorine atoms. This creates a simple, repeating structure of -(CF2-CF2)n-.

The Power of the Carbon-Fluorine Bond

The bond between carbon and fluorine is one of the strongest known in organic chemistry. This immense bond strength is the source of PTFE's signature traits: it gives the material its exceptional resistance to heat and chemical attack.

PTFE vs. Teflon

It is a common point of confusion, but the terms are not interchangeable. PTFE is the generic chemical name for the polymer. Teflon™ is a registered trademark and brand name for products, often PTFE-based, manufactured by Chemours.

Understanding the Trade-offs and Misconceptions

While its properties are exceptional, it's critical to have a balanced understanding of the material and its place in the world of engineering plastics.

Not Just a Coating

While famous for its use in non-stick cookware, the vast majority of PTFE is used in demanding industrial applications, including seals, gaskets, wiring insulation, and chemical-resistant linings where performance is critical.

Performance Has Limits

Despite its thermal and chemical stability, PTFE is a relatively soft material with lower mechanical strength and creep resistance compared to other engineering plastics. This makes it unsuitable for high-load structural applications without reinforcement.

The Brand is Not the Only Source

While Teflon is the most famous brand, many manufacturers produce high-quality PTFE resins and products. The critical factor is specifying the material grade and properties required for the application, not just the brand name.

Applying This Understanding to Your Goal

The legacy of PTFE's discovery informs its use today, from historical context to modern engineering decisions.

- If your primary focus is material science history: The key takeaway is that PTFE's serendipitous discovery highlights the importance of observation and curiosity in scientific breakthroughs.

- If your primary focus is engineering and design: The key takeaway is that PTFE's unique molecular structure provides a powerful and reliable solution for problems involving extreme temperatures, aggressive chemicals, or low-friction surfaces.

This single, accidental discovery in 1938 fundamentally expanded the toolkit available to engineers and scientists for decades to come.

Summary Table:

| Key Aspect | Details |

|---|---|

| Chemical Name | Polytetrafluoroethylene (PTFE) |

| Discovery Date | April 6, 1938 |

| Discoverer | Dr. Roy J. Plunkett |

| Key Property | Extreme chemical inertness, high-temperature resistance, low friction |

| Common Trademark | Teflon™ (by Chemours) |

Leverage the Power of PTFE for Your Application

PTFE's unique properties make it indispensable for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you need high-purity seals, chemical-resistant liners, or custom labware, KINTEK's expertise in precision PTFE manufacturing is your solution.

We specialize in custom fabrication, from initial prototypes to high-volume production, ensuring the material performs exactly as your application requires.

Ready to solve your design challenge with high-performance PTFE components? Contact KINTEK today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials