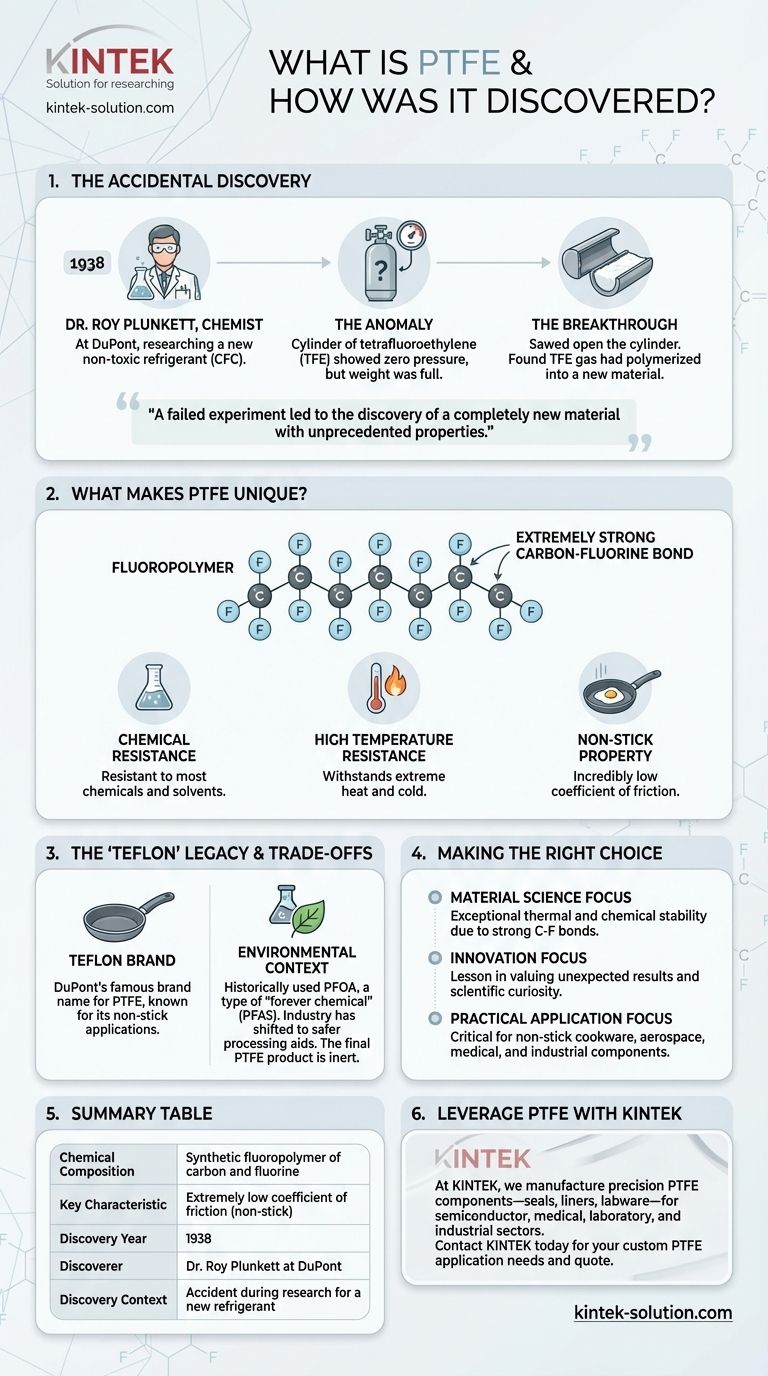

Polytetrafluoroethylene (PTFE) is a material born from a fortunate accident. It is a high-performance synthetic fluoropolymer, a type of plastic consisting of carbon and fluorine atoms. Famously known by its DuPont brand name, Teflon, PTFE was discovered by accident in 1938 by chemist Dr. Roy Plunkett while he was attempting to develop a new, non-toxic refrigerant.

The story of PTFE is a classic example of scientific serendipity. A failed experiment to create a refrigerant led to the discovery of a completely new material with unprecedented properties, all because a chemist chose to investigate an anomaly rather than discard it.

The Anatomy of a Scientific Accident

The discovery of PTFE is one of the most famous stories of accidental invention in modern chemistry. It underscores the importance of curiosity and observation.

The Intended Goal: A New Refrigerant

In 1938, Dr. Roy Plunkett, a chemist at DuPont's Jackson Laboratory in New Jersey, was researching alternative refrigerants. His goal was to create a new, non-toxic chlorofluorocarbon (CFC).

The Anomaly in the Lab

Plunkett was working with a gas called tetrafluoroethylene (TFE). He had stored the gas in pressurized cylinders and, upon preparing for an experiment, found that one of the cylinders had no gas pressure, even though its weight indicated it was still full.

Instead of flowing out as a gas, nothing emerged. Rather than assuming the experiment was a failure, Plunkett and his assistant decided to investigate.

The Moment of Discovery

They sawed the metal cylinder open. Inside, they found that the TFE gas had polymerized—its individual molecules had linked together to form long chains.

This process created a waxy, white powder that was remarkably slippery and inert. Plunkett immediately recognized that he had created a new substance with extraordinary properties.

What Makes PTFE So Unique?

The substance Plunkett found was not a refrigerant, but its molecular structure gave it a combination of properties that engineers had never seen before in a single material.

A Fluoropolymer Explained

PTFE is a fluoropolymer. This means it is a large, chain-like molecule (a polymer) that contains fluorine atoms.

The chemical bond between carbon and fluorine is one of the strongest known in organic chemistry. This immense bond strength is the source of PTFE's most valuable characteristics.

Unprecedented Material Properties

The new material was found to be exceptionally resistant to corrosion from most chemicals and could withstand extremely high temperatures.

Perhaps most famously, it has an incredibly low coefficient of friction. In simple terms, almost nothing sticks to it, making it one of the most slippery materials in existence.

Understanding the Trade-offs

While PTFE's properties are remarkable, a complete understanding requires acknowledging the broader context of fluorochemicals.

Manufacturing and Environmental Concerns

The production of PTFE historically involved the use of other chemicals as processing aids, most notably PFOA (perfluorooctanoic acid).

PFOA is part of a larger class of "forever chemicals" known as PFAS, which have raised significant environmental and health concerns due to their persistence.

A Shift in Industry

In response to these concerns, manufacturers have phased out the use of PFOA in favor of newer processing aids with more favorable safety profiles. It is important to distinguish between the stable, inert final PTFE product and the separate chemicals sometimes used in its manufacturing process.

Making the Right Choice for Your Goal

Understanding the origins of PTFE helps frame its modern applications and legacy. Its discovery was a pivotal moment in materials science.

- If your primary focus is material science: PTFE is a prime example of how the incredibly strong carbon-fluorine bond creates a polymer with exceptional thermal and chemical stability.

- If your primary focus is innovation: The story of its discovery is a powerful lesson in the value of investigating unexpected results and recognizing potential where others might see failure.

- If your primary focus is practical application: This material, born from a lab mistake, is the reason for the convenience of non-stick cookware and critical high-performance coatings in aerospace, medical, and industrial fields.

Ultimately, PTFE stands as a testament to how scientific curiosity can transform a failed experiment into a material that reshapes industries.

Summary Table:

| Property | Description |

|---|---|

| Chemical Composition | Synthetic fluoropolymer of carbon and fluorine |

| Key Characteristic | Extremely low coefficient of friction (non-stick) |

| Discovery Year | 1938 |

| Discoverer | Dr. Roy Plunkett at DuPont |

| Discovery Context | Accident during research for a new refrigerant |

Leverage the unique properties of PTFE for your specialized components.

At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures your project, from prototype to high-volume order, benefits from PTFE's superior chemical resistance and non-stick performance.

Contact KINTEK today to discuss your specific PTFE application needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications