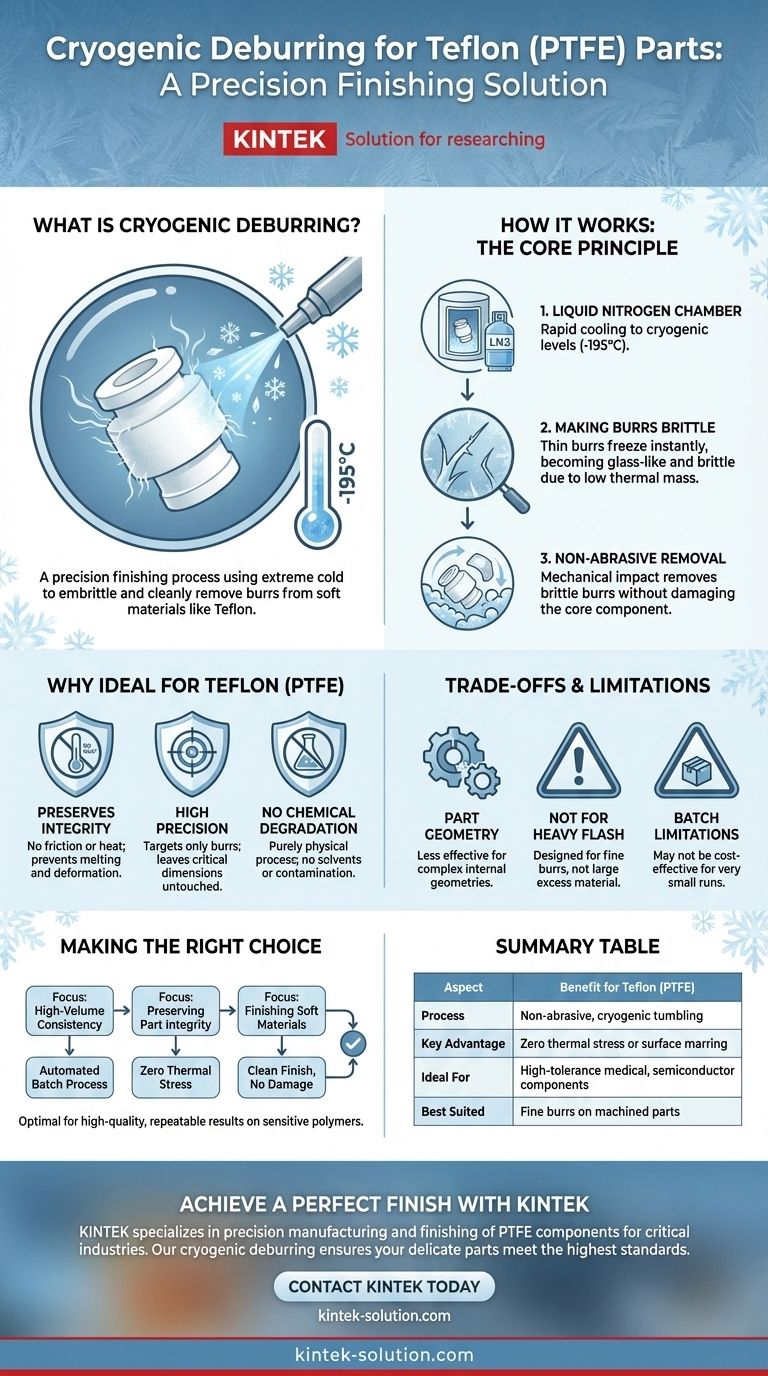

Cryogenic deburring is a precision finishing process that uses extreme cold to remove unwanted material, known as burrs, from manufactured parts. For a soft, heat-sensitive material like Teflon (PTFE), it works by flash-freezing the thin burrs with liquid nitrogen, making them brittle enough to be cleanly fractured and removed without damaging the core component.

The central challenge with Teflon is removing delicate burrs without melting, deforming, or marring the part's surface. Cryogenic deburring solves this by changing the physical state of the unwanted material, allowing for a non-abrasive removal process that preserves the part's critical dimensions and integrity.

The Core Principle: Embrittlement Over Abrasion

Traditional deburring often relies on cutting, grinding, or sanding. These methods are problematic for a soft material like Teflon, as they can easily damage the part. Cryogenic deburring employs a fundamentally different, more elegant approach.

The Role of Liquid Nitrogen

The process takes place in a specialized, insulated chamber. Liquid nitrogen is introduced, rapidly dropping the temperature inside to cryogenic levels, often as low as -195°C (-320°F).

Making Burrs Brittle

The key to the process is thermal mass. The thin, wispy burrs have very little mass and a high surface area, causing them to freeze almost instantly. This rapid temperature drop changes their state from pliable to glass-like and extremely brittle.

Non-Abrasive Removal

While the burrs become brittle, the main body of the Teflon part, with its greater mass, remains more robust. The parts are then gently tumbled, often with a non-abrasive media. The mechanical impact is just enough to shatter the frozen burrs, which break off cleanly at the base.

Why This Process is Ideal for Teflon (PTFE)

Teflon's unique properties make it an excellent candidate for cryogenic deburring, where other methods would fail or introduce unacceptable risk.

Preserving Material Integrity

Teflon has a low melting point and is highly sensitive to heat. Any finishing method involving friction or high temperatures risks deforming the part, ruining its dimensional accuracy. Cryogenic deburring is a cold process that completely avoids this risk.

Achieving High Precision

Because the process targets only the embrittled burrs, the primary surfaces and critical dimensions of the component are left untouched. This is essential for high-tolerance parts used in medical, aerospace, or electronics applications where precision is paramount.

Avoiding Chemical Degradation

While Teflon is known for its chemical resistance, using harsh solvents for deburring is never ideal. Cryogenic deburring is a purely physical process, introducing no chemicals that could potentially compromise the material or require additional cleaning steps.

Understanding the Trade-offs

While highly effective, cryogenic deburring is not a universal solution. Understanding its limitations is key to applying it correctly.

Part Geometry Matters

The process is most effective for parts that can be tumbled in a batch. Components with highly complex internal geometries or deep, blind holes may not be suitable, as the media may not reach all burrs.

Not for Heavy Flashing

Cryogenic deburring is designed to remove fine burrs created during machining. It is not intended to remove large amounts of excess material, or "flash," from a molding process. Heavy flash must be trimmed manually beforehand.

Batch Processing Limitations

The process is done in batches, which is highly efficient for large quantities of similar parts. However, it may be less cost-effective for very small runs or single, unique components.

Making the Right Choice for Your Application

Use these guidelines to determine if cryogenic deburring is the correct solution for your needs.

- If your primary focus is high-volume consistency: This automated batch process delivers repeatable, high-quality results that are impossible to achieve with manual deburring.

- If your primary focus is preserving part integrity: For medical, electronic, or aerospace parts where zero thermal or chemical stress is allowed, this is the safest and most reliable method.

- If your primary focus is finishing soft or delicate materials: For polymers like Teflon, PEEK, or Delrin, cryogenic deburring provides a clean finish without the risk of scratching or deformation.

Ultimately, adopting this process allows you to achieve a superior finish on sensitive materials without compromise.

Summary Table:

| Aspect | Benefit for Teflon (PTFE) |

|---|---|

| Process | Non-abrasive, cryogenic tumbling |

| Key Advantage | Zero thermal stress or surface marring |

| Ideal For | High-tolerance medical, semiconductor, and labware components |

| Best Suited | Fine burrs on machined parts (not heavy flash) |

Achieve a Perfect, Damage-Free Finish on Your Teflon Components

For manufacturers in the semiconductor, medical, and laboratory industries, part integrity is non-negotiable. If your application requires precision Teflon parts free of burrs, heat damage, and deformation, cryogenic deburring is the definitive solution.

KINTEK specializes in the precision manufacturing and finishing of PTFE components. We understand the critical tolerances required for seals, liners, and custom labware. Our expertise ensures your delicate Teflon parts are finished to the highest standard, preserving every critical dimension.

Let us help you eliminate finishing defects. Whether you need a prototype run or high-volume production, our team is equipped to deliver flawless results.

Contact KINTEK today to discuss your specific Teflon deburring needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments