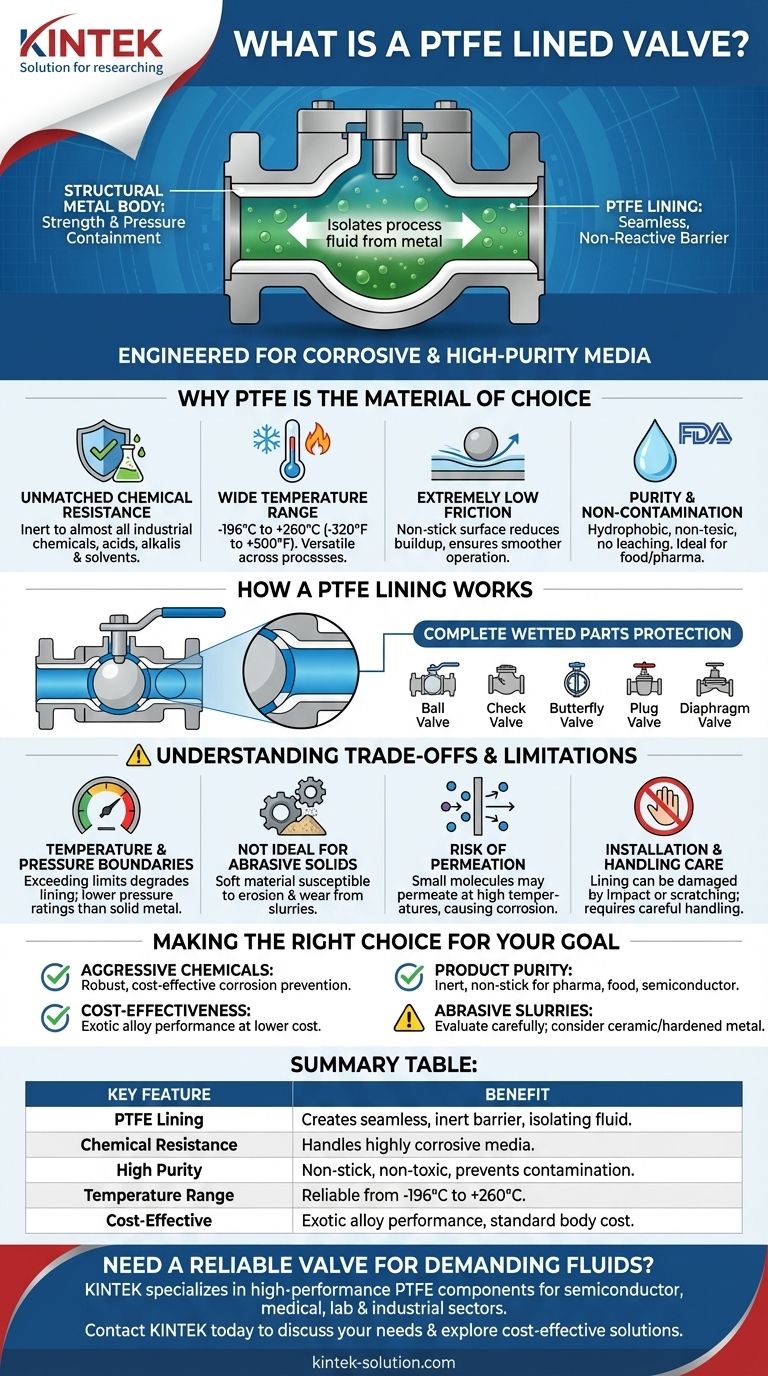

In short, a PTFE lined valve is an industrial valve engineered with an internal lining of Polytetrafluoroethylene (PTFE). This lining creates a seamless, non-reactive barrier that isolates the valve's structural metal components from the fluid passing through it. Its primary function is to handle highly corrosive or high-purity media that would otherwise damage a standard valve or become contaminated.

The core challenge in many industries is controlling corrosive fluids without resorting to prohibitively expensive exotic alloys. A PTFE lined valve solves this by combining the structural strength of common metals with the near-universal chemical inertness of a PTFE lining, offering a high-performance, cost-effective solution.

Why PTFE is the Material of Choice

The effectiveness of a lined valve depends entirely on the properties of the lining material. PTFE is chosen for the most demanding applications due to a unique combination of characteristics.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, alkalis, and organic solvents. This makes it the default choice for services where corrosion is the primary concern.

Wide Temperature Range

PTFE performs reliably across an exceptionally broad temperature spectrum, typically from cryogenic temperatures of -196°C up to +260°C (-320°F to +500°F). This versatility allows its use in a vast range of industrial processes.

Extremely Low Friction

Known as one of the most slippery materials in existence, PTFE has an extremely low coefficient of friction. This non-stick surface prevents media from adhering to the valve's internal parts, reducing buildup and ensuring smoother operation.

Purity and Non-Contamination

PTFE is hydrophobic (it does not absorb water), non-toxic, and can be FDA-approved for food and pharmaceutical contact. Because it is chemically inert, it does not leach impurities into the process fluid, ensuring product purity.

How a PTFE Lining Works in Practice

The design principle is simple but effective: the process fluid only ever touches the PTFE lining, never the structural metal of the valve body.

The Protective Barrier Concept

The valve body, typically made from a cost-effective material like cast iron or carbon steel, provides the necessary mechanical strength and pressure containment. The PTFE liner is molded and locked into place, forming a continuous barrier on all "wetted" surfaces.

Complete Wetted Parts Protection

To be effective, the lining must cover every component that comes into contact with the fluid. In a ball valve, for example, this includes not only the valve body but also the surface of the ball itself.

Common Lined Valve Types

While many valve designs can be lined, the most common include ball valves for quick shut-off, check valves for preventing reverse flow, and butterfly, plug, and diaphragm valves, each suited for different flow control applications.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to successful application.

Temperature and Pressure Boundaries

Although the temperature range is wide, PTFE can degrade if its upper limit is exceeded. Furthermore, lined valves may have lower pressure ratings compared to solid metal alloy valves, as the lining can be affected by extreme pressures.

Not Ideal for Abrasive Solids

PTFE is a relatively soft material. It can be susceptible to erosion and wear when used with fluids containing hard, abrasive solids or slurries, which can eventually compromise the integrity of the liner.

Risk of Permeation

In certain high-temperature applications, very small molecules (like chlorine or hydrogen gas) can slowly pass, or permeate, through the PTFE material. This can lead to corrosion behind the liner and is a critical consideration in specific chemical services.

Installation and Handling Care

The PTFE lining can be damaged by mechanical impact or even by scratching the sealing surfaces during installation. Proper handling and installation procedures are essential to prevent liner damage and ensure a reliable seal.

Making the Right Choice for Your Goal

Selecting a PTFE lined valve is a deliberate engineering choice based on the specific demands of your process.

- If your primary focus is handling aggressive chemicals: A PTFE lined valve is the most robust and cost-effective solution for preventing corrosion and ensuring long service life.

- If your primary focus is product purity: The inert, non-stick, and non-toxic nature of PTFE makes it the ideal choice for pharmaceutical, food-grade, or semiconductor applications.

- If your primary focus is cost-effectiveness for corrosive service: Lined valves deliver the performance of expensive exotic alloys by protecting a lower-cost steel or iron valve body.

- If you are handling abrasive slurries: Carefully evaluate if PTFE is suitable, as a ceramic-lined or hardened metal valve may provide better resistance to wear.

Ultimately, specifying a PTFE lined valve is a strategic decision to isolate a process fluid from a valve's structural material, ensuring both system integrity and longevity.

Summary Table:

| Key Feature | Benefit |

|---|---|

| PTFE Lining | Creates a seamless, inert barrier, isolating fluid from metal valve body. |

| Chemical Resistance | Handles highly corrosive acids, alkalis, and solvents. |

| High Purity | Non-stick, non-toxic surface prevents contamination for sensitive processes. |

| Temperature Range | Operates reliably from -196°C to +260°C. |

| Cost-Effective | Provides performance of exotic alloys at a lower cost by protecting a standard metal body. |

Need a Reliable Valve for Demanding Fluids?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom-fabricated seals, liners, and labware. If you're in the semiconductor, medical, laboratory, or industrial sector and need a valve solution that guarantees corrosion resistance and product purity, we can help.

We combine precision production with custom fabrication, from prototypes to high-volume orders, ensuring your specific application requirements are met.

Contact KINTEK today to discuss your PTFE lined valve needs and explore a cost-effective, high-performance solution for your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications