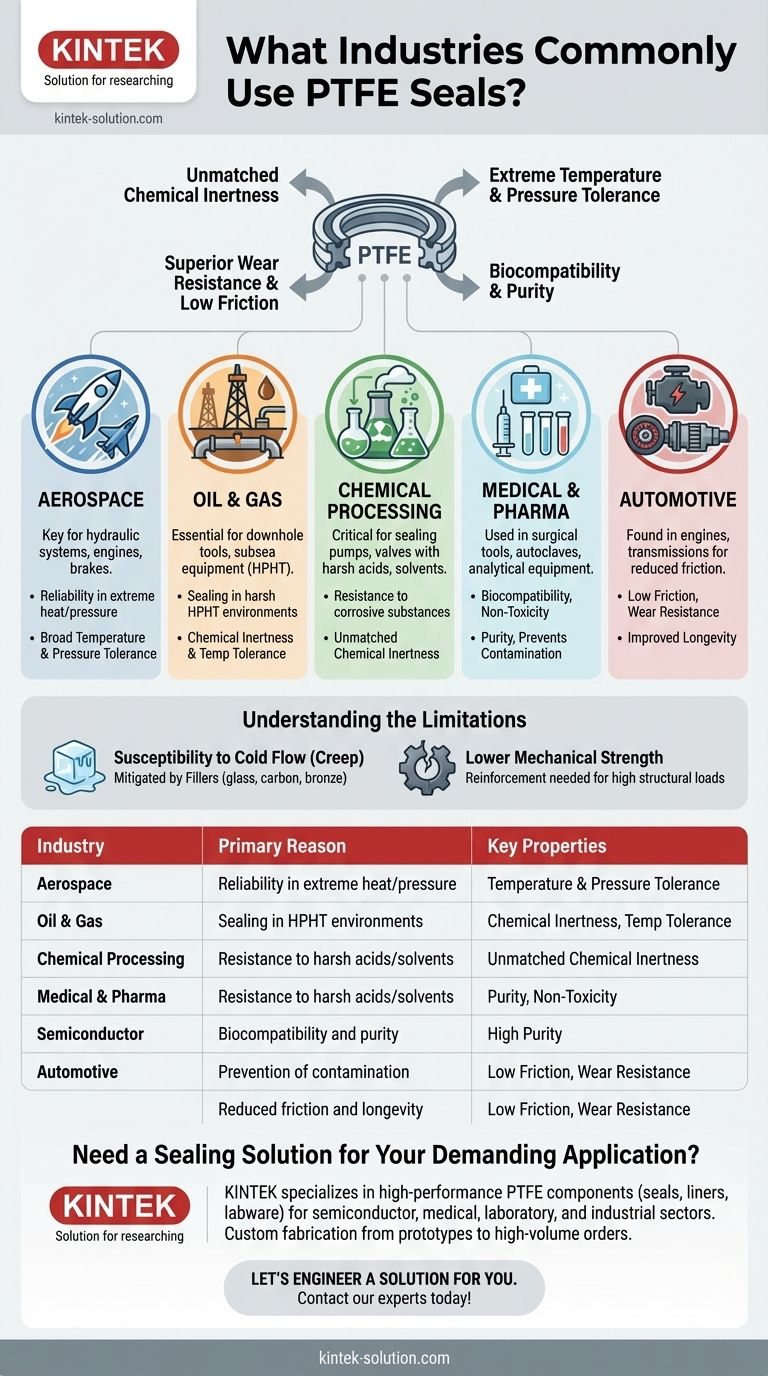

In short, Polytetrafluoroethylene (PTFE) seals are indispensable in nearly every high-performance industry. They are a default choice in sectors like aerospace, oil & gas, chemical processing, medical, and automotive. This widespread adoption is due to PTFE's unique combination of chemical inertness, extreme temperature tolerance, and low-friction properties.

The core reason PTFE seals are so ubiquitous is not just one superior feature, but their unique ability to solve multiple engineering challenges simultaneously—resisting aggressive chemicals, extreme temperatures, and high pressure all at once.

Why PTFE is the Material of Choice for Demanding Applications

The value of a PTFE seal is understood by looking at the problems it solves. Different industries leverage specific properties of the material to ensure reliability, safety, and performance where other materials would fail.

Unmatched Chemical Inertness

For applications involving aggressive or corrosive substances, PTFE is often the only viable option. Its molecular structure makes it non-reactive to almost all industrial chemicals.

This property is critical in the chemical and petrochemical industries for sealing pumps and valves that handle harsh acids and solvents. It is also why the food and pharmaceutical sectors rely on PTFE for non-toxic, non-contaminating seals in processing equipment.

Broad Temperature and Pressure Tolerance

PTFE maintains its integrity across an exceptionally wide temperature range, from cryogenic lows to high-temperature highs. This makes it essential for environments with extreme thermal cycling.

The aerospace industry uses PTFE seals in hydraulic systems, engines, and brakes that must perform reliably under intense heat and pressure. Similarly, the oil & gas industry depends on them for high-pressure, high-temperature (HPHT) applications in downhole tools and subsea equipment.

Superior Wear Resistance and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" minimizes wear and energy loss in dynamic (moving) applications.

This is a key advantage in the automotive industry, where PTFE seals are used in engines and transmissions to reduce friction and improve longevity. Construction machinery like excavators and loaders also uses these seals to withstand the harsh, repetitive movements in their hydraulic systems.

Biocompatibility and Purity

In environments where contamination is unacceptable, PTFE provides an inert, non-toxic, and clean sealing solution. It does not degrade or leach particles into the system.

The medical industry utilizes PTFE in surgical tools, autoclaves, and analytical equipment like hematology analyzers. The semiconductor manufacturing industry also requires the high purity of PTFE to prevent contamination in its ultra-clean production environments.

Understanding the Limitations of PTFE

Despite its remarkable capabilities, PTFE is not a universal solution. Understanding its trade-offs is critical for proper application.

Susceptibility to Cold Flow

The most significant limitation of standard PTFE is its tendency to "creep" or cold flow. When subjected to a constant compressive load, the material can slowly deform over time, potentially compromising the seal.

Engineers mitigate this by incorporating fillers (like glass, carbon, or bronze) into the PTFE matrix to enhance its mechanical strength and resistance to creep.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. In applications requiring high structural integrity and abrasion resistance, a pure PTFE seal might not be sufficient without proper design considerations or reinforcement.

Making the Right Choice for Your Application

Selecting a sealing material depends entirely on the primary demands of the environment.

- If your primary focus is chemical resistance and temperature stability: PTFE is the industry-standard starting point, especially for aerospace, chemical processing, and oil & gas.

- If your primary focus is purity and biocompatibility: PTFE is the ideal choice for medical, pharmaceutical, and semiconductor applications where contamination control is paramount.

- If your primary focus is high mechanical load and wear: A filled PTFE composite or an alternative high-strength polymer may be required to prevent material creep and ensure long-term durability.

Ultimately, leveraging PTFE's strengths while respecting its limitations is the key to engineering a reliable and long-lasting sealing system.

Summary Table:

| Industry | Primary Reason for Using PTFE Seals | Key Properties Utilized |

|---|---|---|

| Aerospace | Reliability in extreme heat/pressure | Temperature & Pressure Tolerance |

| Oil & Gas | Sealing in HPHT environments | Chemical Inertness, Temperature Tolerance |

| Chemical Processing | Resistance to harsh acids/solvents | Unmatched Chemical Inertness |

| Medical & Pharma | Biocompatibility and purity | Purity, Non-Toxicity |

| Semiconductor | Prevention of contamination | High Purity |

| Automotive | Reduced friction and longevity | Low Friction, Wear Resistance |

Need a Sealing Solution for Your Demanding Application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the most challenging environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a seal that leverages PTFE's strengths while mitigating its limitations.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and reliability.

Let's engineer a solution for you. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance