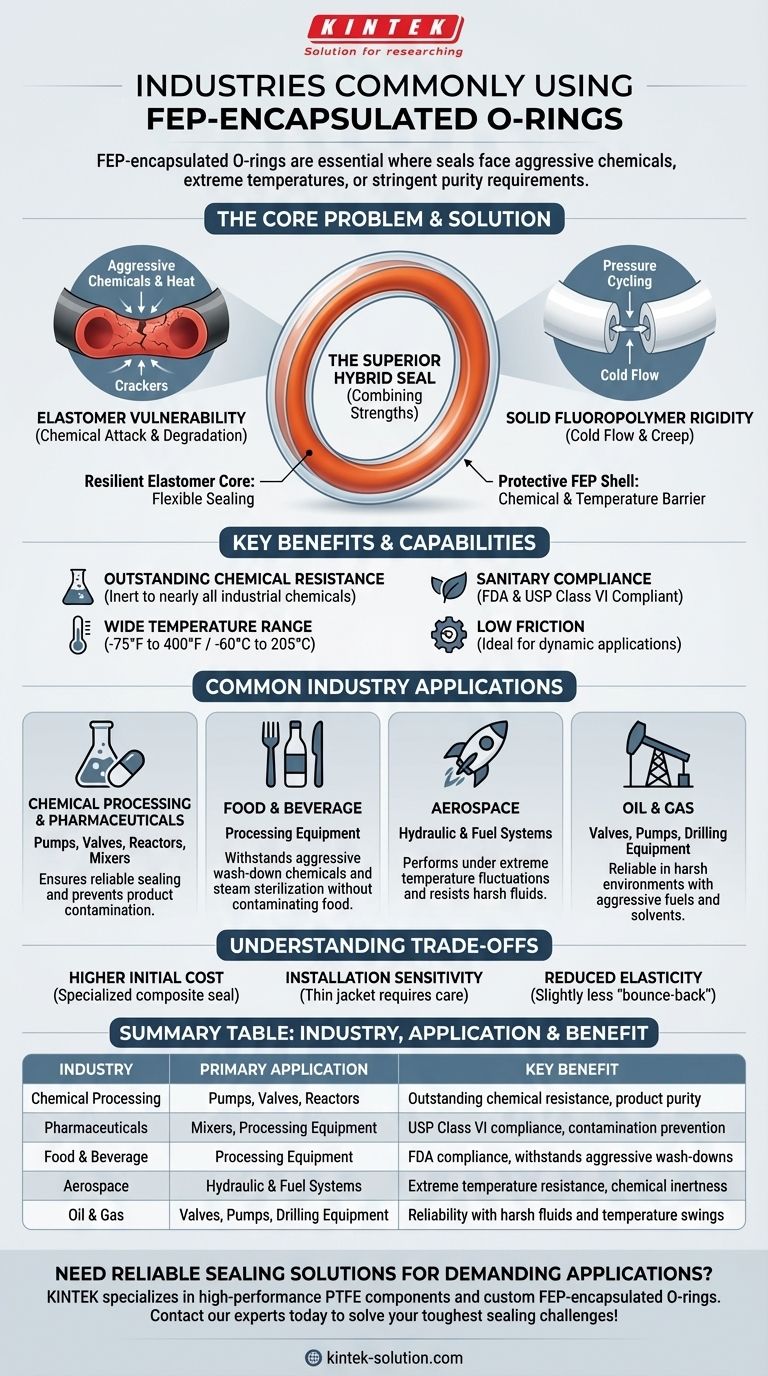

In short, FEP-encapsulated O-rings are used in industries where seals face aggressive chemicals, extreme temperatures, or stringent purity requirements. Key sectors include chemical processing, pharmaceuticals, food and beverage, aerospace, and oil and gas, where they are critical components in equipment like pumps, valves, reactors, and mixers.

The core reason for their adoption is simple: they combine the superior chemical inertness and temperature resistance of a fluoropolymer (FEP) shell with the reliable, flexible sealing capability of a traditional elastomeric (rubber) core. This hybrid design solves sealing challenges where neither material could succeed alone.

The Core Problem: Why Standard Seals Fail

To understand the value of FEP encapsulation, we must first recognize the limitations of the individual materials it combines. Engineers turn to this solution when standard options are compromised.

The Vulnerability of Elastomers

Standard O-rings are made from elastomers like Viton®, Silicone, or EPDM. While these materials offer excellent flexibility and create a tight seal, they degrade quickly when exposed to aggressive acids, solvents, and other harsh chemicals. This chemical attack causes swelling, hardening, or cracking, leading to seal failure.

The Rigidity of Solid Fluoropolymers

Materials like solid PTFE (a close relative of FEP) offer near-universal chemical resistance. However, they are rigid and lack the "memory" or elasticity of rubber. This makes them prone to leaking under pressure cycling and thermal changes, a phenomenon known as cold flow or creep.

How FEP Encapsulation Creates a Superior Seal

FEP-encapsulated O-rings are a composite seal designed to deliver the strengths of both materials without their respective weaknesses.

The Resilient Inner Core

The O-ring has an inner core made of a standard elastomer, typically silicone or Viton® (FKM). This core provides the flexibility and compression needed to maintain a positive seal, just like a standard O-ring.

The Protective Outer Shell

This elastomeric core is seamlessly enclosed in a thin, durable jacket of FEP (Fluorinated Ethylene Propylene). This outer shell acts as an impenetrable barrier, protecting the sensitive core from chemical attack and extreme temperatures.

The Resulting Benefits

This combination provides several key advantages:

- Outstanding Chemical Resistance: The FEP jacket is inert to nearly all industrial chemicals and solvents.

- Wide Temperature Range: They can operate effectively from approximately -75°F to 400°F (-60°C to 205°C).

- Sanitary Compliance: The materials are often FDA compliant and meet USP Class VI standards, making them safe for food, medical, and pharmaceutical use.

- Low Friction: The FEP surface has a very low coefficient of friction, which is ideal for dynamic applications in pumps and valves.

Common Industry Applications

The unique properties of FEP-encapsulated O-rings make them the default choice in several demanding fields.

Chemical Processing & Pharmaceuticals

In this sector, seals are constantly exposed to corrosive substances. FEP encapsulation ensures reliable, long-term sealing in reactors, pumps, and valves, while its purity (USP Class VI) prevents contamination of the final product.

Food & Beverage

Equipment in food processing must withstand aggressive wash-down chemicals and steam sterilization. FDA-compliant FEP-encapsulated O-rings provide the necessary chemical resistance and durability without contaminating the food products.

Aerospace and Oil & Gas

These industries require seals that can perform under extreme temperature fluctuations while resisting aggressive fuels, hydraulic fluids, and solvents. The wide operational temperature range and chemical inertness of FEP-encapsulated seals are critical for safety and reliability.

Understanding the Trade-offs

While highly effective, FEP-encapsulated O-rings are not a universal solution. Understanding their limitations is key to proper application.

Higher Initial Cost

These are specialized, composite seals. Their manufacturing process is more complex, making them significantly more expensive than standard, single-material elastomer O-rings.

Installation Sensitivity

The FEP jacket is relatively thin. Care must be taken during installation to avoid scratching or damaging this outer layer, as any breach will expose the vulnerable inner core and lead to premature failure.

Reduced Elasticity

While far more flexible than a solid PTFE ring, the FEP jacket does slightly reduce the overall elasticity and "bounce-back" of the O-ring compared to a high-performance elastomer alone. This must be considered in gland design for certain dynamic or low-pressure applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your primary operational challenge.

- If your primary focus is maximum chemical purity and resistance: FEP encapsulation is the industry standard for sealing in aggressive chemical, pharmaceutical, or food-grade environments.

- If your primary focus is sealing in extreme temperatures with harsh fluids: The combination of an FEP jacket with a silicone or Viton core is a proven solution for aerospace and energy applications.

- If your primary focus is general-purpose sealing without extreme chemicals: A standard Viton or EPDM O-ring is often a more cost-effective and mechanically forgiving choice.

Ultimately, choosing an FEP-encapsulated O-ring is an engineering decision to protect critical processes from seal failure in the most demanding environments.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical Processing | Pumps, Valves, Reactors | Outstanding chemical resistance, product purity |

| Pharmaceuticals | Mixers, Processing Equipment | USP Class VI compliance, contamination prevention |

| Food & Beverage | Processing Equipment | FDA compliance, withstands aggressive wash-downs |

| Aerospace | Hydraulic Systems, Fuel Systems | Extreme temperature resistance, chemical inertness |

| Oil & Gas | Valves, Pumps, Drilling Equipment | Reliability with harsh fluids and temperature swings |

Need reliable sealing solutions for demanding applications? KINTEK specializes in manufacturing high-performance PTFE components, including custom FEP-encapsulated O-rings. We serve semiconductor, medical, laboratory, industrial, and other specialized industries with precision production from prototypes to high-volume orders. Let us help you solve your toughest sealing challenges—contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE chemically resistant and why is this advantageous? Achieve Unmatched Reliability in Harsh Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What is PTFE (Teflon) and what are its key properties? Unlock Unmatched Chemical & Thermal Resistance

- What factors should be considered when choosing between PTFE lined and hard seal butterfly valves? Ensure Optimal Performance and Safety

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware