Virtually any industry operating under demanding conditions benefits from the use of PTFE rotary shaft seals. Key sectors include oil and gas, aerospace, chemical processing, and food and beverage, where standard rubber seals fail due to extreme temperatures, high speeds, or aggressive chemicals. These seals are not a universal replacement for rubber but are a critical solution for enhancing equipment reliability and lifespan in harsh environments.

The core reason industries turn to PTFE is for its unmatched performance envelope. Its ability to withstand extreme temperatures, resist chemical attack, and handle high rotational speeds makes it the essential choice for applications where operational failure is not an option.

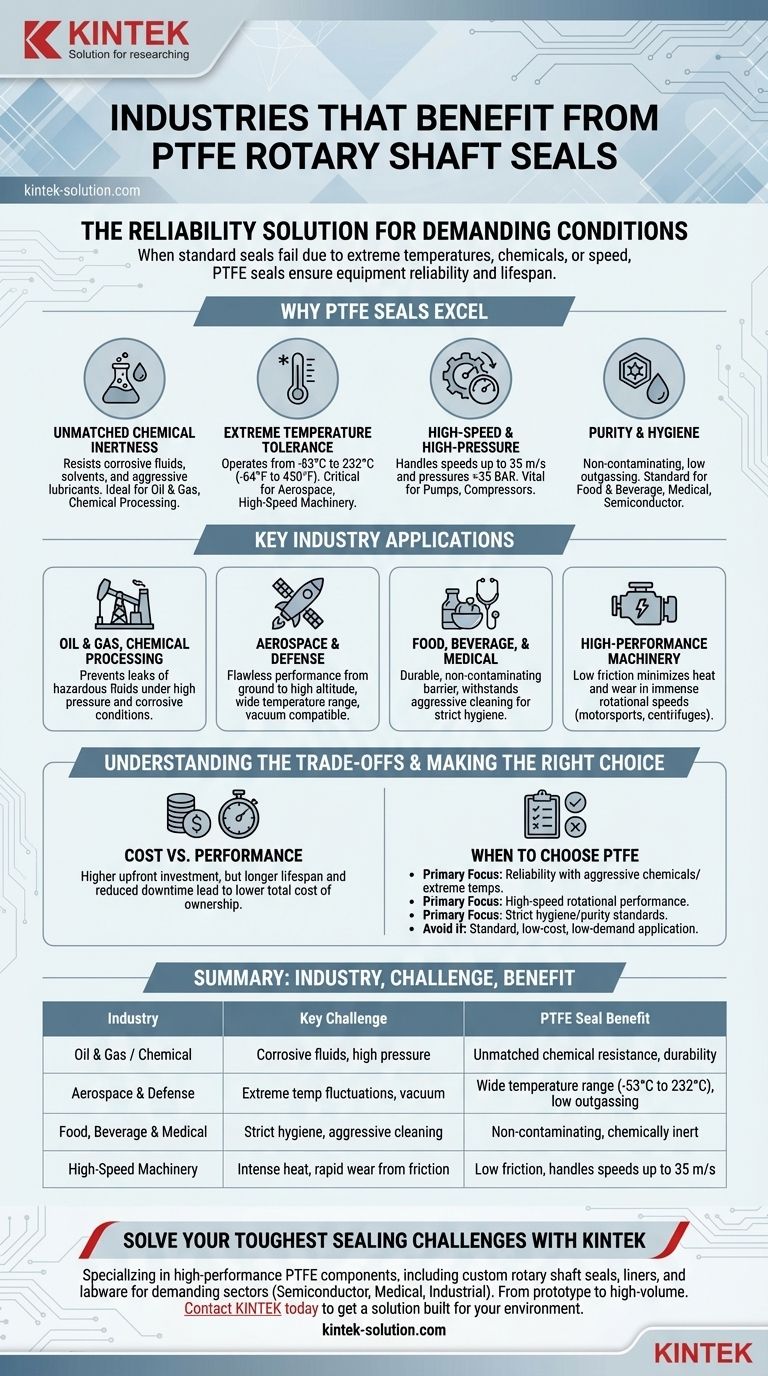

Why PTFE Seals Excel in Demanding Environments

The value of a PTFE seal is not just in the material itself, but in the operational problems it solves. Traditional elastomeric (rubber) seals have clear limitations that PTFE was engineered to overcome.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials available. This makes it indispensable in sectors like chemical processing and oil and gas, where seals are constantly exposed to corrosive fluids, solvents, and aggressive lubricants that would quickly degrade rubber.

Extreme Temperature Tolerance

PTFE seals operate reliably across a vast temperature range, typically from -64°F to 450°F (-53°C to 232°C). This stability is critical for aerospace applications with extreme temperature fluctuations and for high-speed industrial machinery that generates significant heat.

High-Speed and High-Pressure Capability

Compared to rubber, PTFE has a very low coefficient of friction. This allows it to handle extremely high rotational speeds (up to 35 m/s) and pressures (exceeding 35 BAR) without overheating or wearing out prematurely. This is vital for equipment like screw compressors, pumps, and blowers.

Purity and Hygiene

The inert nature of PTFE means it won't contaminate the media it comes into contact with. This property, combined with its low outgassing characteristics, makes it the standard for sensitive applications like food and beverage processing, medical devices, and semiconductor manufacturing.

A Closer Look at Key Industry Applications

Understanding the specific challenges of each industry reveals why PTFE is often the only viable choice.

Oil & Gas and Chemical Processing

In these fields, equipment reliability is paramount. PTFE seals prevent leaks of aggressive and often hazardous fluids, enduring high pressures and corrosive environments that would destroy other materials, thereby reducing costly maintenance and downtime.

Aerospace and Defense

Components in this sector must perform flawlessly under extreme conditions. PTFE's wide temperature range ensures seals remain effective from ground level to high altitudes, while its low outgassing properties are crucial for vacuum and cleanroom environments.

Food, Beverage, and Medical

Cleanliness is non-negotiable. PTFE seals provide a durable, non-contaminating barrier that can withstand frequent and aggressive cleaning cycles, ensuring compliance with strict hygiene standards.

High-Performance Machinery

In applications like automotive motorsports, industrial machine tools, and centrifuges, rotational speeds are immense. The self-lubricating and low-friction nature of PTFE minimizes heat generation and wear, extending the life and performance of critical rotating equipment.

Understanding the Trade-offs

While powerful, PTFE seals are a specialized solution. Objectively evaluating their fit requires understanding their specific context.

Cost vs. Performance

PTFE seals typically represent a higher upfront investment than standard elastomeric seals. However, this cost is often justified by a significantly longer lifespan and reduced equipment downtime, leading to a lower total cost of ownership in the right application.

When a Standard Seal Is Sufficient

For applications operating within moderate temperatures, low speeds, and with non-aggressive media, a traditional rubber seal is often the most cost-effective choice. PTFE is an engineered solution for conditions that exceed the limits of standard materials.

Making the Right Choice for Your Goal

Selecting the correct seal material is fundamental to equipment design and reliability.

- If your primary focus is reliability with aggressive chemicals or extreme temperatures: PTFE seals are the definitive choice, as standard elastomers will likely degrade and cause a premature failure.

- If your primary focus is high-speed rotational performance: The low-friction properties of PTFE will reduce heat generation and wear, extending the life of your equipment far beyond what a rubber seal could achieve.

- If your primary focus is meeting strict hygiene or purity standards: PTFE is the ideal selection for food, medical, or semiconductor applications due to its inherent chemical inertness.

- If your primary focus is a standard, low-cost application: A traditional elastomeric seal is likely the more economical and perfectly adequate solution, provided the operating conditions are not demanding.

By matching the unique capabilities of PTFE to your specific operational challenges, you can ensure your equipment achieves maximum reliability and longevity.

Summary Table:

| Industry | Key Challenge | PTFE Seal Benefit |

|---|---|---|

| Oil & Gas / Chemical | Corrosive fluids, high pressure | Unmatched chemical resistance, durability |

| Aerospace & Defense | Extreme temperature fluctuations, vacuum | Wide temperature range (-53°C to 232°C), low outgassing |

| Food, Beverage & Medical | Strict hygiene, aggressive cleaning | Non-contaminating, chemically inert |

| High-Speed Machinery | Intense heat, rapid wear from friction | Low friction, handles speeds up to 35 m/s |

Ready to Solve Your Toughest Sealing Challenges?

PTFE seals are not a one-size-fits-all solution; they are a precision-engineered answer for applications where failure is not an option. The right seal directly impacts your equipment's reliability, lifespan, and total cost of ownership.

KINTEK specializes in manufacturing high-performance PTFE components—including custom rotary shaft seals, liners, and labware—for the most demanding sectors:

- Semiconductor & Medical for critical purity standards.

- Industrial & Specialized Machinery for extreme pressures and speeds.

We combine precision production with custom fabrication, from prototypes to high-volume orders, ensuring you get a seal that matches your exact operational requirements.

Don't let seal failure dictate your downtime. Contact KINTEK today to discuss your application and get a solution built for your environment.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges