At its core, the non-stick property of Polytetrafluoroethylene (PTFE) is leveraged by any industry where preventing material adhesion is critical for efficiency, purity, or performance. The most prominent beneficiaries are the food and beverage, industrial manufacturing, and packaging sectors, as the non-stick surface simplifies cleaning, reduces product waste, and ensures smoother operational flow.

The true value of PTFE's non-stick characteristic is not just that materials slide off easily, but that this single property translates directly into reduced downtime, higher product quality, and simplified maintenance across a surprisingly diverse range of industrial applications.

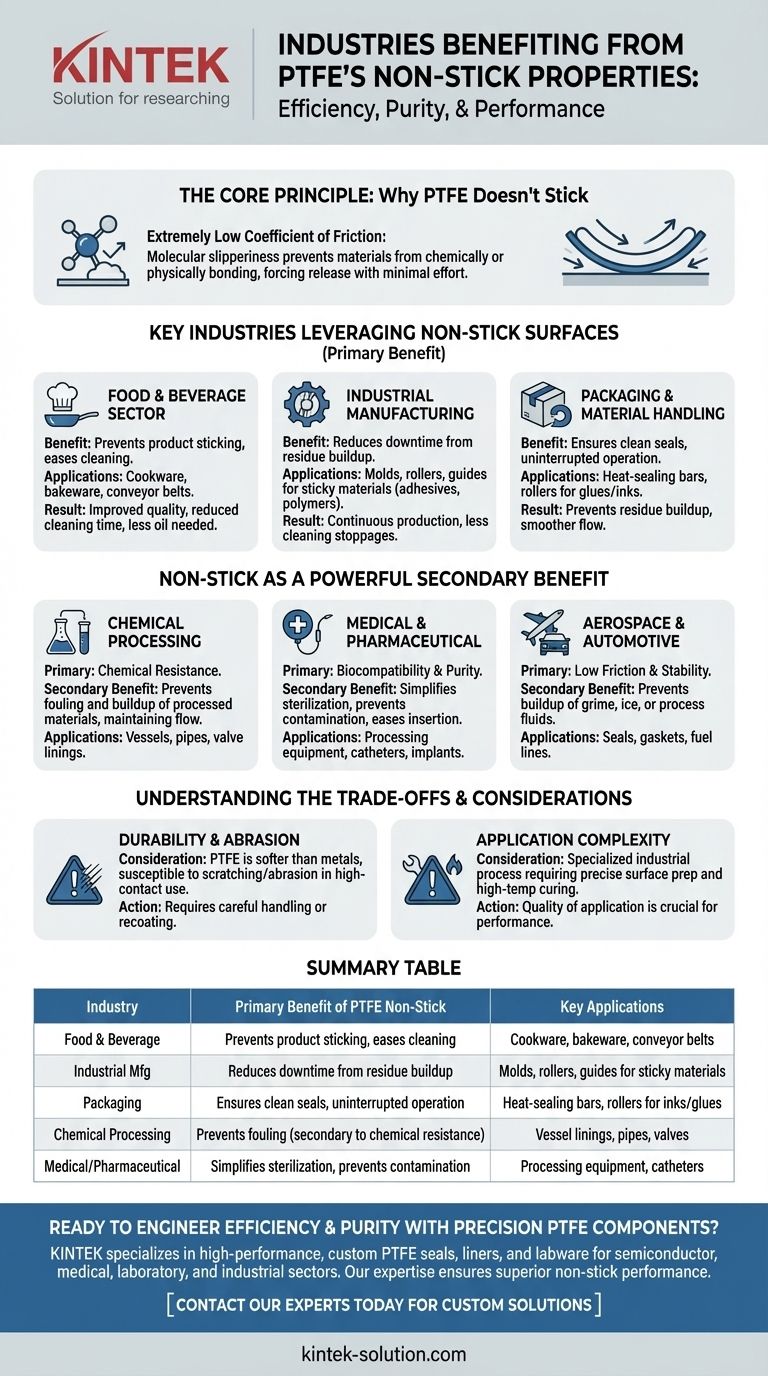

The Core Principle: Why PTFE Doesn't Stick

An Extremely Low Coefficient of Friction

PTFE's effectiveness comes from its uniquely low coefficient of friction. This means very few materials can chemically or physically bond to its surface.

This molecular-level slipperiness is what prevents everything from food to industrial adhesives from gaining a foothold, forcing them to release with minimal effort.

Key Industries Leveraging Non-Stick Surfaces

While many sectors use PTFE for its other properties like chemical resistance or electrical insulation, these industries specifically capitalize on its non-stick nature.

The Food and Beverage Sector

This is the most well-known application. PTFE coatings on cookware, bakeware, and conveyor belts prevent food products from sticking during processing and cooking.

This not only improves the final product's quality but also drastically reduces cleaning time and the need for release agents like oils or fats.

Industrial Manufacturing

In manufacturing, machinery components like molds, rollers, and guides are often coated with PTFE. This prevents product adhesion, especially with sticky materials like adhesives, polymers, or resins.

The result is a more continuous and efficient production process with less downtime required for cleaning clogged equipment.

Packaging and Material Handling

Packaging machinery that handles glues, inks, or plastic films benefits immensely from PTFE's non-stick surface.

It prevents residue from building up on heat-sealing bars, rollers, and guides, ensuring clean seals and uninterrupted operation.

Where Non-Stick is a Powerful Secondary Benefit

In some industries, PTFE is chosen for a primary reason like chemical inertness, but its non-stick property provides a crucial secondary advantage.

Chemical Processing

Vessels, pipes, and valves in chemical plants are often lined with PTFE primarily for its exceptional resistance to corrosive chemicals.

The non-stick surface is a valuable bonus, as it helps prevent fouling and the buildup of processed materials on internal surfaces, maintaining flow and purity.

Medical and Pharmaceutical

PTFE is used for medical devices, implants, and pharmaceutical processing equipment largely because it is biocompatible and maintains high purity.

Its non-stick nature is critical in applications like catheters to ease insertion and in processing equipment to prevent contamination and simplify sterilization between batches.

Aerospace and Automotive

In these sectors, PTFE is often used for seals, gaskets, and fuel lines. The primary drivers are its low friction for wear resistance and its chemical stability.

However, its non-stick quality contributes to the performance of these components by preventing the buildup of grime, ice, or process fluids.

Understanding the Trade-offs

While powerful, the application of PTFE for its non-stick properties is not without practical considerations that must be managed.

Durability and Abrasion

PTFE coatings, especially in high-contact applications, are softer than metals and can be susceptible to scratching and abrasion.

Damage to the surface diminishes its non-stick performance over time, requiring careful handling or eventual recoating to maintain effectiveness.

Application Complexity

Applying a durable and uniform PTFE coating is a specialized industrial process. It requires precise surface preparation and curing at high temperatures to ensure proper adhesion and performance.

This is not a simple paint-on solution, and the quality of the application is just as important as the material itself.

Making the Right Choice for Your Goal

- If your primary focus is product purity and ease of cleaning: PTFE is the industry standard in food, beverage, and pharmaceutical processing for preventing material adhesion and contamination.

- If your primary focus is manufacturing efficiency and reduced downtime: Applying PTFE to machine components in packaging or industrial production lines directly prevents residue buildup that causes stoppages.

- If your primary focus is handling corrosive materials: Choose PTFE for its chemical inertness, and you will gain the powerful secondary benefit of a non-fouling, easy-to-clean surface.

Ultimately, leveraging PTFE's non-stick property is a strategic decision to engineer efficiency and cleanliness directly into your process.

Summary Table:

| Industry | Primary Benefit of PTFE Non-Stick | Key Applications |

|---|---|---|

| Food & Beverage | Prevents product sticking, eases cleaning | Cookware, bakeware, conveyor belts |

| Industrial Manufacturing | Reduces downtime from residue buildup | Molds, rollers, guides for sticky materials |

| Packaging | Ensures clean seals, uninterrupted operation | Heat-sealing bars, rollers for inks/glues |

| Chemical Processing | Prevents fouling (secondary to chemical resistance) | Vessel linings, pipes, valves |

| Medical/Pharmaceutical | Simplifies sterilization, prevents contamination | Processing equipment, catheters |

Ready to engineer efficiency and purity into your process with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the superior non-stick performance and chemical resistance your application demands, from prototypes to high-volume orders.

Contact our experts today to discuss your specific needs and discover how KINTEK's PTFE solutions can reduce your downtime and enhance product quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications