At its core, a piston seal is a fundamental component in virtually every industry that relies on hydraulic or pneumatic power. These seals are critical for containing pressure and preventing fluid bypass within cylinders, enabling controlled linear motion. You will find them everywhere, from massive construction equipment and industrial presses to precision medical devices and aerospace systems.

The widespread use of piston seals stems from a single, critical function: converting fluid pressure into reliable linear force. The specific industry and application simply dictate the material and design required to withstand the unique challenges of pressure, temperature, friction, and chemical exposure.

The Core Function: Enabling Fluid Power

Piston seals are the linchpin of reciprocating systems. They create a seal between a piston and a cylinder bore, allowing pressurized fluid or gas on one side to generate force and movement while preventing it from leaking to the other side.

Hydraulic Systems

In hydraulic systems, piston seals must withstand immense pressures to generate significant force. This is the principle behind heavy machinery.

Applications include construction equipment (like excavators and loaders), industrial presses, automotive plant machinery, and oil-field drilling equipment. The focus here is on durability and high-pressure performance.

Pneumatic Systems

Pneumatic systems operate at lower pressures but often at much higher speeds. The seals in these applications must be responsive and, critically, low-friction.

You see these in high-speed automation, such as can and package filling machines, robotics, and general manufacturing, where fast, repeatable motion is essential.

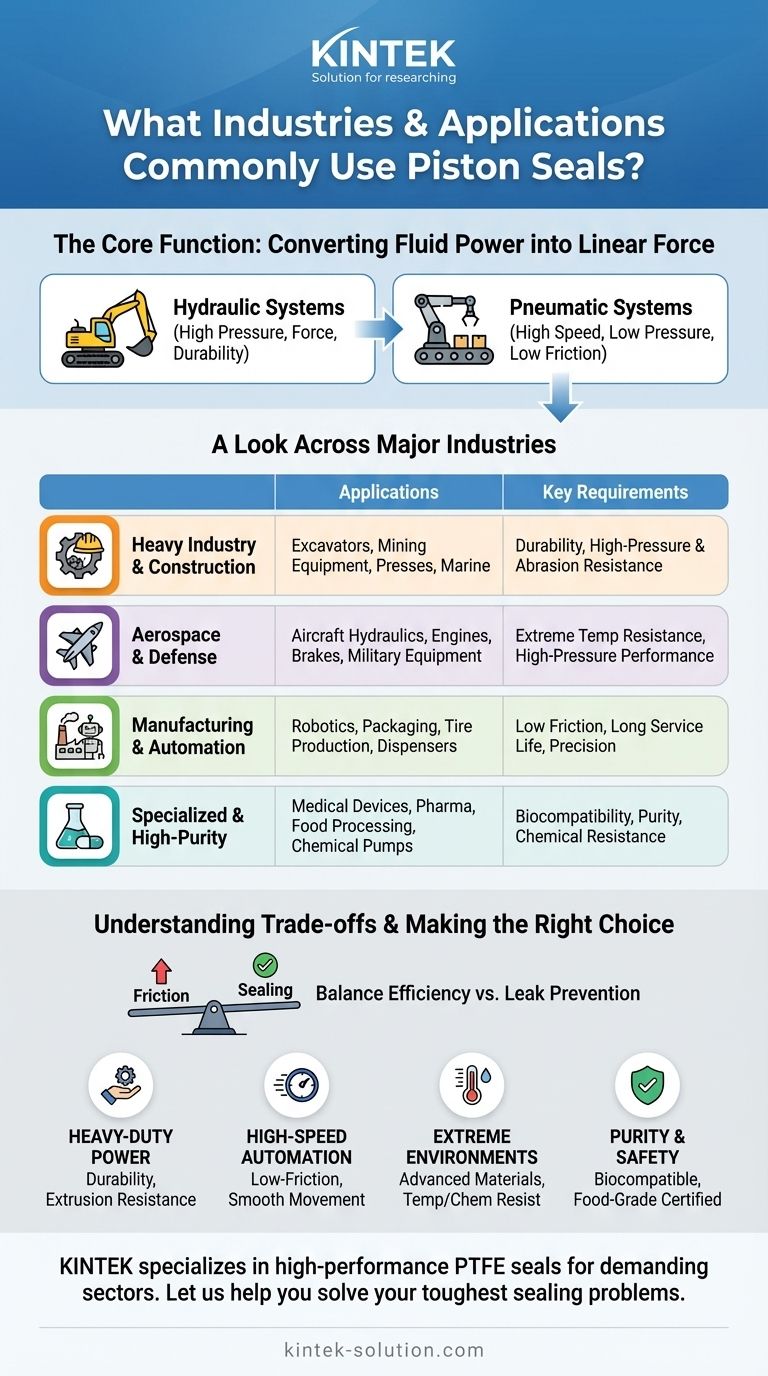

A Look Across Major Industries

While the function is consistent, the operating environments change dramatically between industries, demanding different seal characteristics.

Heavy Industry & Construction

This sector requires seals that can survive brutal conditions. They must resist abrasion, high loads, and contamination from dirt and debris.

Key examples include mining equipment, steel works, marine applications, and the previously mentioned construction machinery. Durability is the single most important factor.

Aerospace & Defense

Applications in aerospace and defense push seals to their absolute limits. They are found in aircraft hydraulic systems, engines, brakes, and military equipment.

Seals in this field must perform flawlessly across extreme temperature ranges, from cryogenic fluids to high-temperature engine compartments, all while handling significant pressure.

Manufacturing & Automation

Precision and reliability are paramount in manufacturing. Piston seals are integral to the automated systems that power modern factories.

Common uses include tire production, domestic goods manufacturing, and adhesive dispensing cylinders. Here, long service life and consistent, low-friction performance are key to minimizing downtime.

Specialized & High-Purity Applications

Certain industries require seals made from specialized materials to meet stringent safety and purity standards.

In the pharmaceutical and food processing industries, seals must be made from food-grade or biocompatible materials. For chemical pumps, seals must offer extreme resistance to corrosive fluids.

Understanding the Trade-offs

Choosing a piston seal is not a one-size-fits-all decision. It involves balancing competing demands based on the specific application.

The Friction vs. Sealing Dilemma

A very tight seal prevents all leakage but can create high friction. This increases energy consumption, generates heat, and can cause "stick-slip" motion, which reduces precision.

Engineers must choose a seal design and material that provides an adequate seal with the lowest possible friction to ensure efficient and smooth operation.

Material Properties Dictate Use

The seal material is just as important as its design. A standard rubber seal that works perfectly in a simple pneumatic cylinder would fail instantly in a high-temperature aerospace application.

Specialized materials like PTFE are chosen for their unique properties. Its wear and temperature resistance make it ideal for construction and aerospace, while its biocompatibility is essential for medical tools like surgical instruments and hematology analyzers.

The High Cost of Failure

A failed piston seal does more than just stop a machine. It can cause fluid leaks, contaminate products, damage expensive equipment, and create significant safety hazards.

This is why selecting a robust, application-appropriate seal is not a cost-saving measure but a critical investment in system reliability and safety.

Making the Right Choice for Your Goal

To select the correct piston seal, you must first define the primary demand of your system.

- If your primary focus is heavy-duty power: Prioritize seals with high durability, extrusion resistance, and the ability to handle extreme pressures, common in hydraulic construction and mining equipment.

- If your primary focus is high-speed automation: Select low-friction seals designed for pneumatic systems to ensure smooth, rapid, and efficient movement with minimal wear.

- If your primary focus is extreme environments: You must specify seals made from advanced materials (like specialized PTFE blends) that can withstand high temperatures, aggressive chemicals, or cryogenic conditions.

- If your primary focus is purity and safety: Insist on seals certified as biocompatible or food-grade to meet the strict regulatory demands of medical, pharmaceutical, or food processing applications.

Ultimately, matching the seal's capabilities to the application's demands is the key to unlocking reliable, efficient, and safe performance.

Summary Table:

| Industry | Primary Application | Key Seal Requirements |

|---|---|---|

| Heavy Industry & Construction | Excavators, Mining Equipment, Presses | Durability, High-Pressure Resistance, Abrasion Resistance |

| Aerospace & Defense | Aircraft Hydraulics, Brakes, Engines | Extreme Temperature Resistance, High-Pressure Performance |

| Manufacturing & Automation | Robotics, Packaging Machines, Tire Production | Low Friction, Long Service Life, Precision |

| Medical & Pharmaceutical | Surgical Instruments, Hematology Analyzers | Biocompatibility, Purity, Chemical Resistance |

Ensure Unmatched Reliability for Your Critical Applications

Selecting the right piston seal is crucial for the performance, safety, and longevity of your equipment. The wrong choice can lead to downtime, product contamination, or even system failure.

KINTEK specializes in manufacturing high-performance PTFE seals and components that meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal precisely engineered for your unique pressure, temperature, and chemical exposure challenges.

Let us help you solve your toughest sealing problems.

Contact our engineering team today for a consultation on custom PTFE piston seals that deliver precision, durability, and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability