In short, PTFE gaskets are used in nearly every demanding industrial sector. Their unique properties make them indispensable in applications ranging from chemical processing and petrochemical plants to food, beverage, and pharmaceutical manufacturing. They are also critical components in power generation, aerospace, and for sealing equipment like pumps, valves, and compressors.

The widespread adoption of PTFE gaskets is not accidental. It stems directly from the material's unparalleled chemical inertness, wide operating temperature range, and inherent purity, which together solve the most difficult sealing challenges across industries.

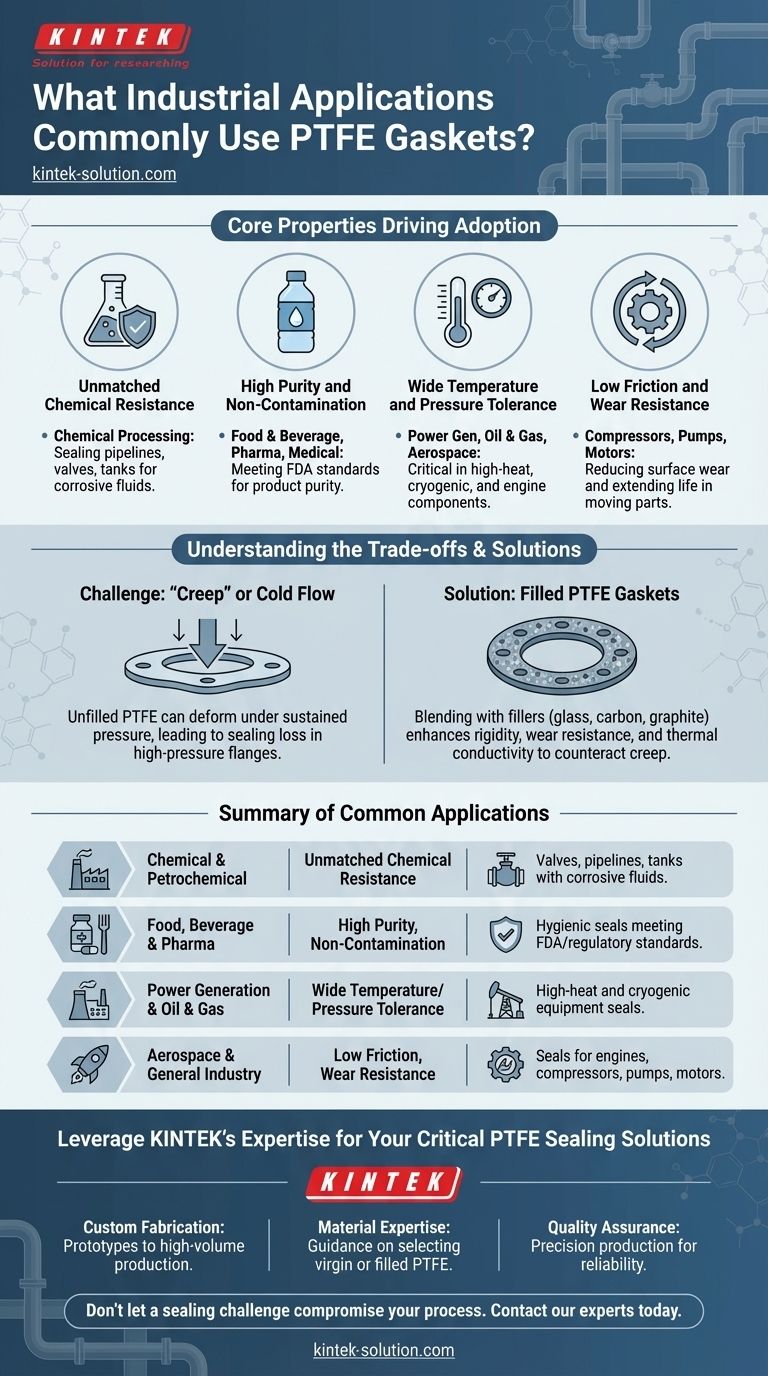

The Core Properties Driving Adoption

The reason PTFE is so ubiquitous is that it possesses a combination of characteristics that are difficult to find in any other single material. Different industries prioritize different properties, but PTFE's versatility makes it a frequent first choice.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and caustics. This makes it the default choice in aggressive environments.

This property is critical in petrochemical and chemical processing plants for sealing pipelines, valves, tanks, and fittings that handle corrosive fluids.

High Purity and Non-Contamination

PTFE is an inherently pure polymer that does not leach or contaminate the media it contacts. It can meet stringent regulatory standards like those from the FDA.

This makes it essential in food and beverage processing, pharmaceutical manufacturing, and medical device applications where product purity and hygienic conditions are non-negotiable.

Wide Temperature and Pressure Tolerance

PTFE gaskets can maintain their integrity and sealing capability across an exceptionally broad temperature range, from cryogenic lows to high-heat applications.

This resilience is vital for equipment in power generation facilities, oil and gas operations, and demanding aerospace components like engines.

Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This reduces surface wear and energy loss in dynamic applications.

This is a key advantage for sealing moving parts in equipment like compressors, pumps, and electric motors, where minimizing friction extends component life.

Understanding the Trade-offs

While PTFE is a superior sealing material, it is not without limitations. Understanding these trade-offs is crucial for successful application and proper gasket selection.

The Challenge of "Creep" or Cold Flow

Unfilled, virgin PTFE can be susceptible to creep, also known as cold flow. Under sustained pressure and temperature, the material can slowly deform, potentially leading to a loss of sealing force over time.

This is a critical consideration in high-pressure flange applications where maintaining bolt torque and a consistent seal is paramount.

The Role of Fillers in Enhancing Performance

To counteract creep and improve mechanical properties, PTFE is often blended with filler materials like glass, carbon, or graphite. These fillers enhance the gasket's rigidity, wear resistance, and thermal conductivity.

This creates a class of "filled PTFE" gaskets that are far more resistant to deformation, making them suitable for more demanding mechanical and high-pressure duties.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket requires aligning the material's properties with the specific demands of your operating environment.

- If your primary focus is handling highly corrosive chemicals: Virgin PTFE is often the best choice due to its absolute chemical inertness.

- If your primary focus is ensuring absolute product purity: Use a virgin or specially formulated, FDA-compliant PTFE gasket for food, beverage, or pharmaceutical applications.

- If your primary focus is high-pressure or high-temperature service: A filled PTFE gasket (e.g., with glass or carbon) is necessary to resist creep and maintain a reliable seal.

- If your primary focus is sealing dynamic equipment like pumps: A filled PTFE gasket will provide the necessary wear resistance and low-friction properties for a longer service life.

Ultimately, understanding the unique strengths of PTFE allows you to leverage it as one of the most versatile and reliable sealing solutions available.

Summary Table:

| Industry | Key PTFE Property Utilized | Common Applications |

|---|---|---|

| Chemical & Petrochemical | Unmatched chemical resistance | Valves, pipelines, tanks with corrosive fluids |

| Food, Beverage & Pharma | High purity, non-contamination | Hygienic seals meeting FDA/regulatory standards |

| Power Generation & Oil & Gas | Wide temperature/pressure tolerance | High-heat and cryogenic equipment seals |

| Aerospace & General Industry | Low friction, wear resistance | Seals for engines, compressors, pumps, motors |

Leverage KINTEK's Expertise for Your Critical PTFE Sealing Solutions

Selecting the right PTFE gasket—whether virgin for ultimate chemical resistance or filled for high-pressure stability—is critical to your operation's safety, efficiency, and compliance. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and labware.

We serve demanding sectors like semiconductor, medical, laboratory, and industrial industries, offering:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Material Expertise: Guidance on selecting virgin or filled PTFE to perfectly match your application's chemical, temperature, and pressure requirements.

- Quality Assurance: Precision production that ensures reliability and longevity in even the most challenging environments.

Don't let a sealing challenge compromise your process. Contact our experts today to discuss your specific needs and discover how KINTEK's PTFE solutions can enhance your equipment's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments