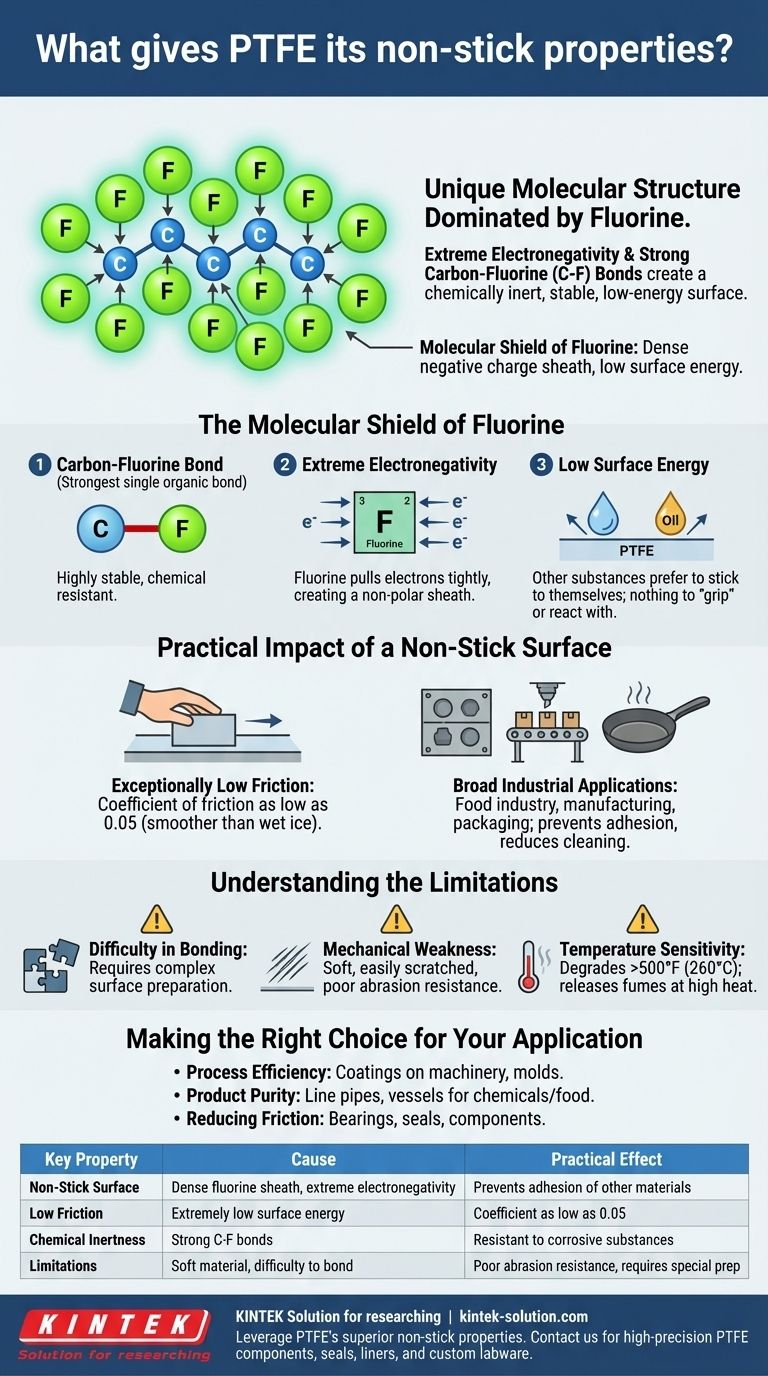

The non-stick property of Polytetrafluoroethylene (PTFE) is a direct result of its unique molecular structure, dominated by fluorine atoms. These atoms create a chemically inert and low-energy surface that effectively prevents other materials from forming a bond with it.

The core reason PTFE is non-stick lies in the extreme electronegativity of its fluorine atoms. These atoms create a stable, non-reactive molecular shield with very low surface energy, giving other substances nothing to "grip" or react with.

The Molecular Shield of Fluorine

To understand PTFE's behavior, we must look at its atomic composition. The material is built on a simple, repeating structure that gives it its remarkable properties.

The Carbon-Fluorine Bond

PTFE consists of a long chain of carbon atoms, which forms a stable backbone. Each carbon atom is bonded to two fluorine atoms.

This carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry. This immense strength makes the molecule highly stable and resistant to chemical attack.

Extreme Electronegativity

Fluorine is the most electronegative element on the periodic table. This means it has an exceptionally strong attraction for electrons.

In the PTFE molecule, the fluorine atoms pull the bonding electrons so tightly toward themselves that they create a dense, uniform sheath of negative charge around the carbon backbone. This leaves no residual charge on the surface for other molecules to be attracted to.

Low Surface Energy

The result of this stable, non-polar structure is an extremely low surface energy. The PTFE surface is so chemically content and non-reactive that other substances find it more energetically favorable to stick to themselves than to the PTFE.

This is why water and oils bead up and slide off effortlessly. They are repelled not by an active force, but by the complete absence of any attractive force from the PTFE surface.

Practical Impact of a Non-Stick Surface

This unique molecular property translates directly into valuable real-world characteristics that are leveraged across many industries.

Exceptionally Low Friction

Because other molecules cannot adhere to the surface, the force required to move an object across it is minimal.

PTFE exhibits one of the lowest coefficients of friction of any known solid. Its static coefficient is around 0.05, and its kinetic coefficient can be as low as 0.1, making it smoother than wet ice on wet ice.

Broad Industrial Applications

This combination of non-stick and low-friction properties is invaluable.

It is used in the food industry for non-stick cookware and food processing equipment to improve efficiency and simplify cleaning. In industrial manufacturing, it prevents product adhesion on machinery and reduces residue buildup in packaging systems.

Understanding the Limitations

While its primary property is a significant advantage, it also creates inherent trade-offs that are critical to understand.

Difficulty in Bonding

The very quality that makes PTFE non-stick also makes it extremely difficult to bond to other materials. Applying a PTFE coating to a metal pan, for instance, requires complex surface preparation techniques like sandblasting or chemical etching to create a mechanical grip.

Mechanical Weakness

PTFE is a relatively soft material. It has poor resistance to abrasion and can be easily scratched by harder materials, which is why metal utensils can damage non-stick cookware.

Temperature Sensitivity

Although chemically stable, PTFE has a relatively low melting point compared to metals. At temperatures above 500°F (260°C), it can begin to degrade, and at much higher temperatures, it can release potentially harmful fumes.

Making the Right Choice for Your Application

Understanding the source of PTFE's properties allows you to deploy it effectively based on your primary goal.

- If your primary focus is process efficiency: Use PTFE coatings on machinery, molds, and conveyor belts to prevent product buildup and reduce cleaning downtime.

- If your primary focus is product purity: Line pipes and vessels with PTFE to handle corrosive chemicals or prevent cross-contamination in food and pharmaceutical applications.

- If your primary focus is reducing friction: Employ PTFE in bearings, seals, or other mechanical components where low friction is more critical than high mechanical strength.

Ultimately, PTFE's non-stick nature is a masterclass in how fundamental atomic properties can create profoundly useful macroscopic behaviors.

Summary Table:

| Key Property | Cause | Practical Effect |

|---|---|---|

| Non-Stick Surface | Dense sheath of fluorine atoms with extreme electronegativity | Prevents adhesion of other materials |

| Low Friction | Extremely low surface energy | Coefficient of friction as low as 0.05 |

| Chemical Inertness | Strong carbon-fluorine bonds | Resistant to corrosive substances |

| Limitations | Soft material, difficult to bond | Poor abrasion resistance, requires special surface prep |

Leverage PTFE's superior non-stick properties for your application. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures optimal performance and purity. Contact our team today to discuss your specific requirements and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials