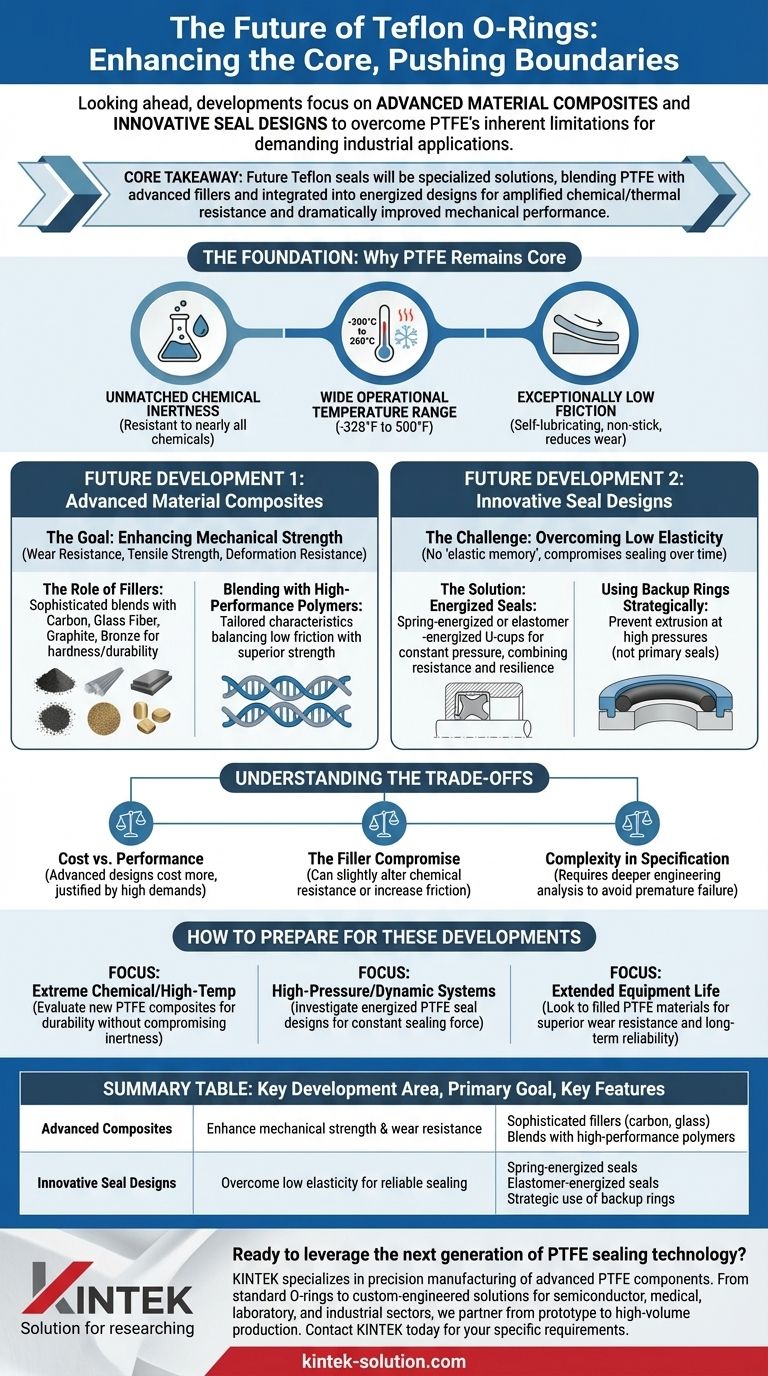

Looking ahead, the future of Teflon O-rings is not about replacing the core PTFE material but enhancing it. Developments are focused on creating advanced material composites and innovative seal designs to overcome PTFE's inherent physical limitations, pushing its capabilities into more demanding applications across all industrial sectors.

The core takeaway is that future Teflon seals will increasingly be specialized solutions. Expect to see PTFE blended with advanced fillers and integrated into energized designs that amplify its exceptional chemical and thermal resistance while dramatically improving its mechanical performance.

The Foundation: Why PTFE Remains a Core Material

Before looking at future developments, it's critical to understand why Polytetrafluoroethylene (PTFE), the material in Teflon products, is so valuable. Its fundamental properties are the baseline upon which all innovation is built.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This makes it the default choice for sealing applications in aggressive chemical processing, pharmaceuticals, and manufacturing.

Wide Operational Temperature Range

Standard PTFE is exceptionally stable across a vast temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F). This allows it to function reliably in cryogenic applications as well as high-heat environments.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating, non-stick surface is ideal for dynamic seals in rotating or reciprocating equipment, reducing wear and energy consumption.

Future Development 1: Advanced Material Composites

The most significant area of development is in material science. While virgin PTFE is chemically robust, it is mechanically soft and can be prone to "cold flow" or creep under load. Future materials address this directly.

The Goal: Enhancing Mechanical Strength

The primary objective of creating PTFE composites is to improve properties like wear resistance, tensile strength, and resistance to deformation under pressure.

The Role of Fillers

Future advancements will focus on more sophisticated blends of PTFE with fillers. Adding materials like carbon, glass fiber, graphite, or bronze fundamentally changes the mechanical properties, making the O-ring harder and more durable for high-pressure or dynamic applications.

Blending with High-Performance Polymers

Expect to see more proprietary blends where PTFE is combined with other high-performance polymers. This creates composite materials with tailored characteristics, balancing PTFE's low friction with the superior mechanical strength of another polymer.

Future Development 2: Innovative Seal Designs

Parallel to material science, innovations in the physical design of seals are unlocking new performance levels by compensating for PTFE's low elasticity.

The Challenge: Overcoming Low Elasticity

Unlike rubber elastomers, a solid PTFE O-ring does not have good "elastic memory." Once compressed, it does not spring back to its original shape effectively, which can compromise sealing performance over time.

The Solution: Energized Seals

The future lies in hybrid designs. Spring-energized or elastomer-energized seals use a U-cup or jacket made from a low-friction PTFE composite, while an internal spring or rubber O-ring provides constant pressure. This gives you the best of both worlds: the chemical resistance of PTFE on the outside and the reliable resilience of a spring or elastomer on the inside.

Using Backup Rings Strategically

While not a new concept, the use of PTFE backup rings in new, higher-pressure applications is a critical design trend. These rings don't seal but prevent the primary O-ring from extruding into the clearance gap, allowing softer, more effective sealing materials to be used at much higher pressures.

Understanding the Trade-offs

These advancements offer incredible benefits, but as a technical advisor, I must emphasize that they come with important trade-offs.

Cost vs. Performance

Advanced composites and energized seal designs are significantly more expensive than standard O-rings. Their use must be justified by performance requirements that commodity seals cannot meet.

The Filler Compromise

Adding fillers to PTFE to boost mechanical strength can sometimes slightly alter its core properties. For example, certain fillers may reduce the overall chemical resistance compared to virgin PTFE or increase the coefficient of friction.

Complexity in Specification

With a wider array of materials and designs, the selection process becomes more complex. Choosing the wrong filler or design for an application can lead to premature failure. This demands a deeper level of engineering analysis during the specification phase.

How to Prepare for These Developments

To make the right choice, align your evaluation of these future technologies with your primary engineering goal.

- If your primary focus is sealing in extreme chemical or high-temperature environments: Prioritize evaluating new PTFE composites that offer enhanced durability without compromising the material's fundamental inertness.

- If your primary focus is reliability in high-pressure or dynamic systems: Investigate energized PTFE seal designs that provide a constant, resilient sealing force where a standard O-ring would fail.

- If your primary focus is extending equipment life and reducing maintenance: Look to filled PTFE materials that offer superior wear resistance, justifying a higher upfront cost with long-term reliability.

By understanding these trends, you can select sealing solutions that are not only effective today but are also aligned with the future of industrial performance.

Summary Table:

| Key Development Area | Primary Goal | Key Features |

|---|---|---|

| Advanced Composites | Enhance mechanical strength & wear resistance | Sophisticated fillers (carbon, glass); Blends with high-performance polymers |

| Innovative Seal Designs | Overcome low elasticity for reliable sealing | Spring-energized seals; Elastomer-energized seals; Strategic use of backup rings |

Ready to leverage the next generation of PTFE sealing technology?

KINTEK specializes in the precision manufacturing of advanced PTFE components, including seals, liners, and labware. Whether you need a standard O-ring or a custom-engineered, high-performance composite solution for the semiconductor, medical, laboratory, or industrial sectors, we have the expertise.

We partner with you from prototype to high-volume production to ensure your application achieves maximum reliability, chemical resistance, and longevity.

Contact KINTEK today to discuss your specific requirements and discover the right PTFE solution for your future needs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the PTFE ball valve operate? A Guide to Reliable, Corrosion-Resistant Flow Control

- What are the different types of PTFE packing available? Choose the Right Seal for Your Application

- What control options are available for PTFE/PFA lined ball valves? Choose the Right Actuation Method

- In which industries are PTFE bellows commonly used due to their chemical resistivity? Essential for Corrosive & Pure Environments

- In which industries are EPTFE gaskets commonly used? Critical Sealing Solutions for Demanding Environments

- What is PTFE packing and what are its primary characteristics? Master Sealing for Extreme Conditions

- What are some key applications of low-friction PTFE in bearings and bushings? Achieve Maintenance-Free Performance

- What are spring-energized seals? An Active Sealing Solution for Extreme PTFE Applications