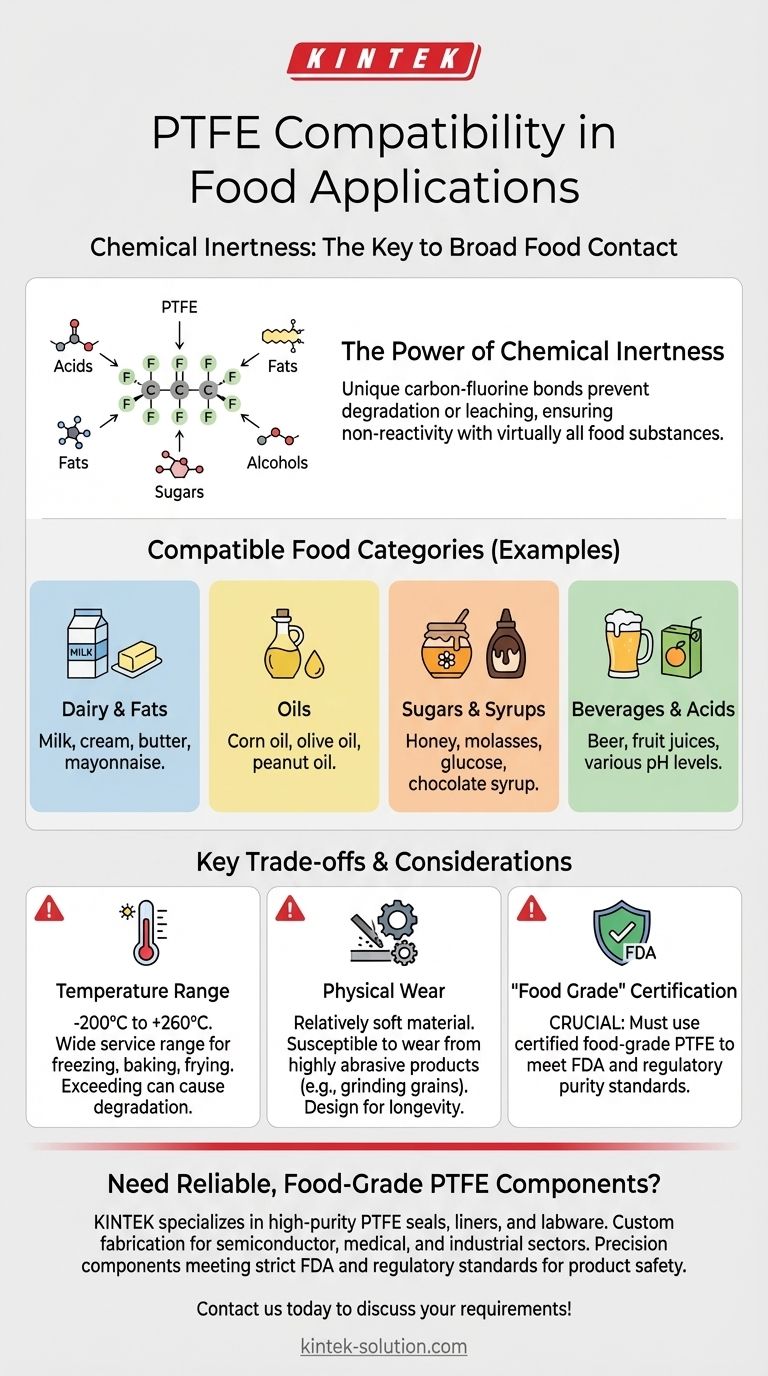

In short, Polytetrafluoroethylene (PTFE) is compatible with an exceptionally wide range of food-related substances. Its chemical inertness makes it suitable for direct contact with products including beer, butter, milk, cream, various food oils (corn, olive, peanut), fruit juices, honey, molasses, and chocolate syrup. This broad compatibility is a primary reason for its widespread use in the food processing industry.

The core reason for PTFE's extensive food compatibility is not a specific list of approved items, but its fundamental chemical inertness. It simply does not react with the acids, fats, sugars, or alcohols found in virtually all food products.

The Principle of Chemical Inertness

PTFE's performance in food applications stems from its unique molecular structure. The strong carbon-fluorine bonds make the material highly non-reactive, preventing it from degrading or leaching into the products it touches.

Broad Food Category Compatibility

PTFE shows excellent resistance across all major food categories. This is not an exhaustive list but demonstrates its versatility.

- Dairy and Fats: It is fully compatible with milk, cream, butter, buttermilk, and mayonnaise.

- Oils: It safely handles a wide variety of food oils, including corn, cottonseed, olive, and peanut oil.

- Sugars and Syrups: PTFE is an excellent choice for processing high-sugar content products like glucose, honey, molasses, and chocolate syrup.

- Beverages and Acidic Products: It has no issue with beer, fruit juices, or other substances with varying pH levels.

Resistance Beyond Food Products

To understand its reliability, it's useful to know that PTFE's compatibility extends to aggressive industrial chemicals.

It is rated as excellent for use with acids (acetic, hydrochloric), alcohols (ethyl, methyl), and industrial agents like ammonia and hydrogen peroxide. This extreme durability is why it so easily handles the much milder chemical compositions of food.

Understanding the Trade-offs and Limitations

While chemically robust, PTFE is not without practical limitations. A true technical assessment requires understanding its physical and regulatory constraints.

Temperature Range

PTFE has a very wide and useful service temperature range, typically from -200°C to +260°C (-328°F to +500°F). This covers almost all food processing applications, from cryogenic freezing to baking and frying. However, exceeding its upper limit can cause it to degrade.

Physical Wear and Abrasion

PTFE is a relatively soft material. In applications involving highly abrasive food products, such as grinding grains or mixing crystalline sugars, it can be susceptible to physical wear over time. This should be a key consideration for equipment longevity and design.

The Importance of "Food Grade" Certification

Crucially, not all PTFE is created equal. For any food-related application, you must use a material that is certified as food-grade. This ensures it is manufactured to specific purity standards and is free from contaminants, meeting regulations set by bodies like the U.S. Food and Drug Administration (FDA).

Making the Right Choice for Your Application

Your specific goal will determine how you leverage PTFE's properties.

- If your primary focus is versatility: PTFE is an outstanding choice for multi-purpose equipment that will handle a wide variety of acidic, fatty, or sugary products without risk of corrosion or contamination.

- If your primary focus is durability against abrasion: You should consider filled grades of PTFE or other materials if the application involves constant contact with hard, abrasive particulates.

- If your primary focus is regulatory compliance: Always demand and verify that the specific PTFE you source is certified as food-grade by the relevant authorities for your region.

Ultimately, PTFE's chemical stability makes it one of the most reliable and widely used materials for direct food contact when its physical properties are matched to the application.

Summary Table:

| Food Category | Examples of Compatible Substances |

|---|---|

| Dairy & Fats | Milk, cream, butter, mayonnaise |

| Oils | Corn oil, olive oil, peanut oil |

| Sugars & Syrups | Honey, molasses, chocolate syrup |

| Beverages & Acids | Beer, fruit juices |

Need reliable, food-grade PTFE components for your application?

KINTEK specializes in manufacturing high-purity PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get precision components that meet strict FDA and regulatory standards, guaranteeing chemical inertness and product safety.

Contact us today to discuss your specific requirements and benefit from our expertise in material compatibility!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments