The most common fillers for PTFE balls are glass, carbon, graphite, and bronze. More specialized fillers like molybdenum disulfide (MoS₂) and polyamide are also used to achieve specific performance characteristics, while simple color pigments can be added for identification. These additives are blended with the base PTFE resin to enhance its mechanical properties.

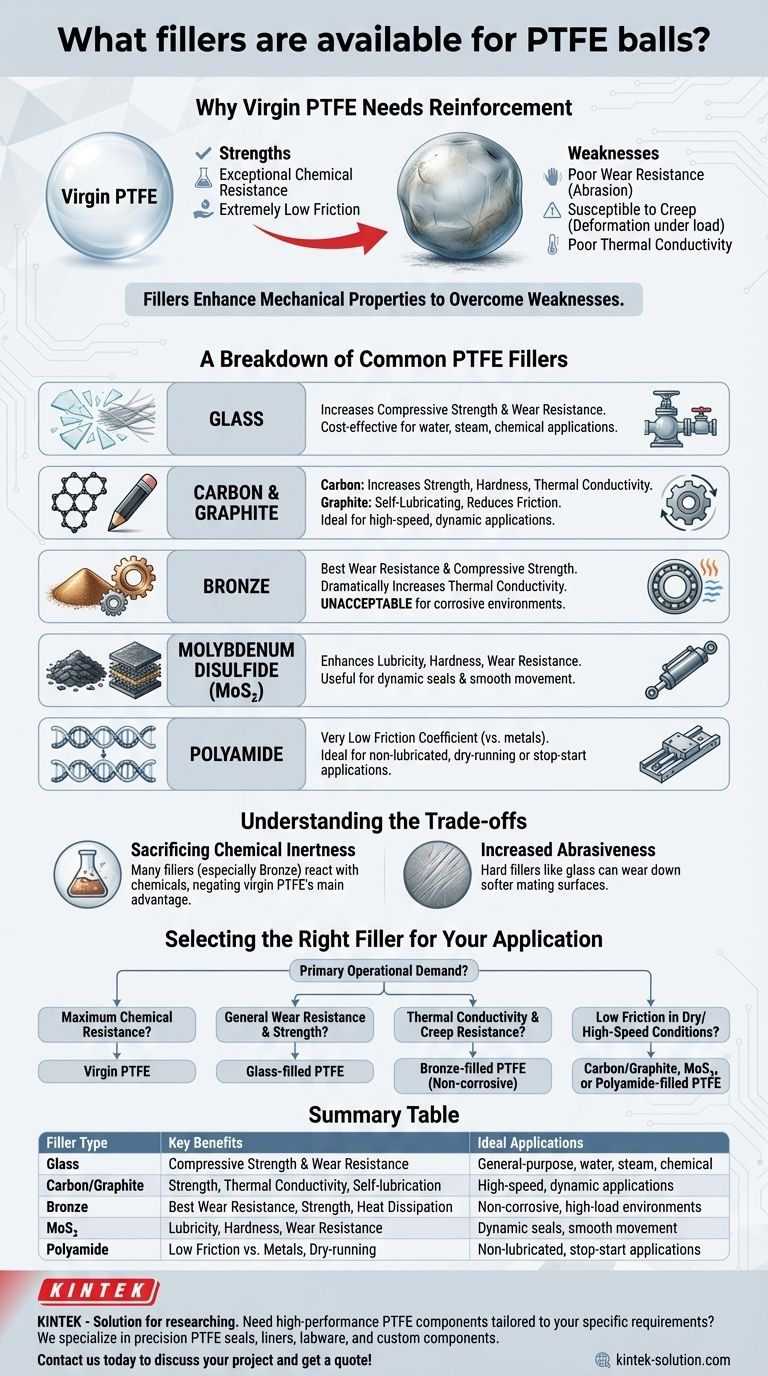

The core reason for adding fillers to PTFE is to overcome its inherent weaknesses—namely, poor resistance to wear and deformation under load (creep). While virgin PTFE offers exceptional chemical resistance and low friction, fillers are necessary to improve its strength, durability, and thermal conductivity for demanding mechanical applications.

Why Virgin PTFE Needs Reinforcement

The Strengths of Virgin PTFE

Virgin PTFE is a remarkable material known for its near-universal chemical compatibility. It is resistant to almost all industrial chemicals, acids, and solvents.

It also possesses an extremely low coefficient of friction, making it one of the most slippery materials known. This is ideal for applications where smooth, non-stick surfaces are required.

The Weaknesses Fillers Address

The primary drawback of virgin PTFE is its softness. It has poor wear resistance and is susceptible to abrasion, especially in dynamic applications like bearings or seals.

It also suffers from creep, or deformation under a sustained load. Over time, a virgin PTFE ball in a valve seat, for example, can slowly change shape and compromise the seal. Finally, it has poor thermal conductivity, meaning it doesn't dissipate heat well.

A Breakdown of Common PTFE Fillers

Glass

Glass fiber is one of the most common and cost-effective fillers. It significantly increases compressive strength and wear resistance compared to virgin PTFE.

It's a great general-purpose choice for water, steam, and chemical applications where improved durability is needed.

Carbon and Graphite

Carbon is often added to increase compressive strength and hardness. It provides good wear resistance and improved thermal conductivity.

Graphite is frequently blended with carbon. Its primary benefit is reducing the coefficient of friction, acting as a self-lubricant for the material. A carbon/graphite blend is excellent for high-speed, dynamic applications.

Bronze

Bronze powder provides the best improvement in wear resistance and compressive strength among common fillers. It also dramatically increases thermal conductivity, helping to dissipate heat in high-speed applications.

However, bronze is a metallic filler and significantly reduces the material's chemical resistance, making it unsuitable for corrosive environments.

Molybdenum Disulfide (MoS₂)

Often used in combination with other fillers like glass or bronze, molybdenum disulfide (MoS₂) enhances lubricity. It lowers the coefficient of friction while also increasing the material's hardness and wear resistance.

This filler is particularly useful for dynamic seals and applications requiring smooth, consistent movement.

Polyamide

Polyamide is a synthetic polymer filler that offers a very low friction coefficient, especially against surfaces like stainless steel, brass, and aluminum.

It is ideal for non-lubricated, dry-running, or stop-start applications where it minimizes wear on both the ball and the mating surface.

Understanding the Trade-offs

Sacrificing Chemical Inertness

The primary trade-off is chemical resistance. While virgin PTFE is nearly inert, fillers are not.

Fillers like bronze are easily attacked by acids and corrosive chemicals, completely negating one of PTFE's primary advantages. Glass-filled PTFE also has reduced resistance to certain strong acids and bases.

Increased Abrasiveness

Hard fillers like glass can be abrasive to softer mating surfaces. A glass-filled PTFE ball might cause premature wear on a valve seat made of a softer plastic or certain metals.

This is why fillers like polyamide or graphite are chosen for applications involving sensitive or softer counter-surfaces.

Selecting the Right Filler for Your Application

Choosing the correct material depends entirely on the operational demands of your system.

- If your primary focus is maximum chemical resistance: Virgin PTFE is the only suitable choice.

- If your primary focus is general wear resistance and strength: Glass-filled PTFE offers a balanced and cost-effective performance boost.

- If your primary focus is thermal conductivity and creep resistance: Bronze-filled PTFE excels, provided the environment is not chemically aggressive.

- If your primary focus is low friction in dry or high-speed conditions: A carbon/graphite, molybdenum disulfide, or polyamide-filled PTFE will provide the best self-lubricating properties.

Ultimately, matching the filler's specific benefits to your application's unique challenges is the key to engineering success.

Summary Table:

| Filler Type | Key Benefits | Ideal Applications |

|---|---|---|

| Glass | Increases compressive strength & wear resistance | General-purpose, water, steam, chemical applications |

| Carbon/Graphite | Improves strength, thermal conductivity, and self-lubrication | High-speed, dynamic applications |

| Bronze | Best wear resistance, compressive strength, and heat dissipation | Non-corrosive, high-load environments |

| Molybdenum Disulfide (MoS₂) | Enhances lubricity, hardness, and wear resistance | Dynamic seals, smooth movement applications |

| Polyamide | Low friction against metals, ideal for dry-running | Non-lubricated, stop-start applications |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise in material science ensures optimal performance for your application.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What temperature range can expanded PTFE gaskets withstand? From Cryogenic -200°C to High-Temp 260°C

- Why is PTFE used for gaskets? Superior Sealing for Harsh Chemical & Temperature Environments

- What are the best practices for installing and maintaining PTFE expansion joints? Ensure Maximum Safety and Reliability

- When should RPTFE not be used? Avoid Component Failure with HF and Caustics

- In what types of environments are PTFE lip seals commonly used? Ideal for Extreme Conditions

- What are the key benefits of PTFE oil seals? Superior Performance in Extreme Conditions

- What are the symptoms of a leaking PTFE butterfly valve? Identify External & Internal Leaks