Selecting the right PTFE rotary seal is a critical engineering decision that extends beyond the seal itself to encompass the entire hardware system. To ensure reliable performance, you must evaluate a combination of operating conditions, hardware characteristics, and the specific seal design. Key factors include the rotational speed and system pressure, the shaft's surface finish and hardness, compatibility with the sealing media, and the precise dimensions of the seal groove.

The central challenge in selecting a PTFE rotary seal lies in its inherent lack of elasticity compared to traditional rubber seals. This means success is not about finding a single component, but about designing a cohesive system where the seal, shaft, and housing are perfectly matched to the application's demands.

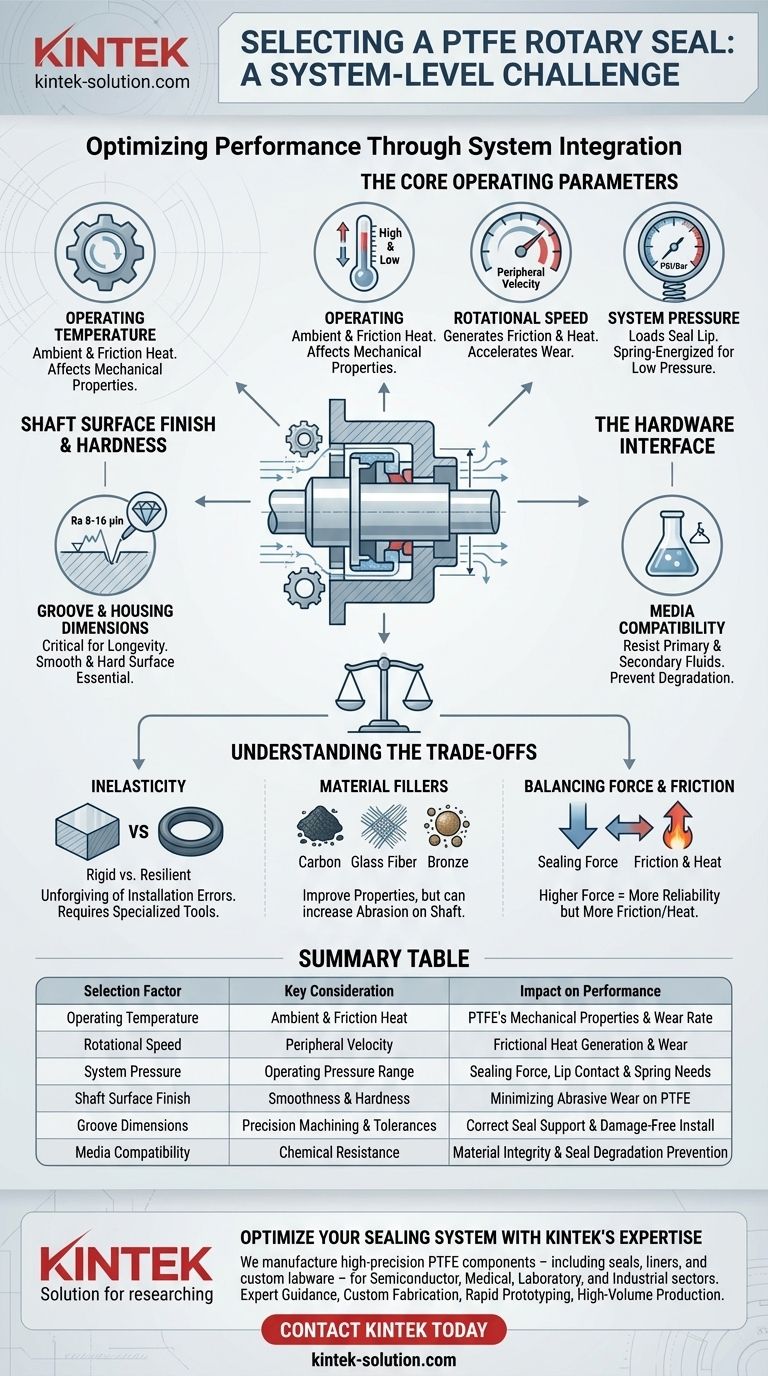

The Core Operating Parameters

To begin your selection process, you must first define the environment in which the seal will operate. These three parameters—temperature, speed, and pressure—form the foundation of your decision.

Operating Temperature

The functional temperature range directly impacts the mechanical properties of PTFE. High temperatures can soften the material, increasing wear, while low temperatures can cause it to stiffen, reducing its ability to seal effectively. You must consider both the ambient and the friction-generated heat.

Rotational Speed

Higher rotational speeds generate more friction at the sealing lip, leading to increased localized heat and accelerated wear. The Peripheral Velocity (speed at the shaft surface) is the critical metric here, as it dictates the amount of energy the seal must dissipate.

System Pressure

The operating pressure directly loads the seal lip against the shaft. High pressure can improve sealing but may also increase friction and wear. For very low-pressure or vacuum applications, a simple lip seal may not have enough inherent force, often requiring a spring-energized design to maintain contact.

The Hardware Interface

A PTFE seal does not work in isolation. Its performance is inextricably linked to the hardware it seals against. Ignoring the characteristics of the shaft and housing is a common cause of premature failure.

Shaft Surface Finish and Hardness

This is arguably the most critical factor for PTFE seal longevity. Because PTFE is a relatively soft material, it requires a very smooth shaft surface (typically 8-16 µin Ra) to minimize abrasive wear. Furthermore, the shaft must be sufficiently hard to resist being worn down by the seal material and any fillers it may contain.

Groove and Housing Dimensions

Unlike resilient rubber seals that can be squeezed into place, the rigidity of PTFE demands high-precision machining of the seal groove. Proper dimensions and tolerances are non-negotiable to ensure the seal is correctly supported and loaded without being damaged during installation.

Media Compatibility

You must confirm the chemical compatibility of the PTFE compound with the primary fluid being sealed. It is also crucial to account for any secondary fluids, such as cleaning agents or system flushes, that may come into contact with the seal during the equipment's lifecycle.

Understanding the Trade-offs

PTFE is a high-performance material, but its unique properties present specific challenges and trade-offs that must be managed. Objectively assessing these limitations is key to a successful design.

The Challenge of Inelasticity

The primary trade-off with PTFE is its rigidity. While this provides excellent resistance to extrusion and wear, it makes the seal unforgiving of installation errors. Sharp corners on the shaft or housing can easily damage the seal lip, and specialized installation tools are often required.

Material Fillers and Their Impact

Base PTFE is rarely used alone. Fillers like carbon, glass fiber, or bronze are added to improve properties like wear resistance, creep resistance, and thermal conductivity. However, these fillers can make the seal more abrasive, demanding a harder shaft surface to prevent system wear.

Balancing Sealing Force and Friction

A seal with a higher sealing force (e.g., from a more robust spring) will provide a more reliable barrier, especially at low pressures. The trade-off is higher friction, which generates more heat and can reduce the operational speed limit and the overall service life of both the seal and the shaft.

Making the Right Choice for Your Application

Ultimately, the optimal seal is a balanced solution tailored to your primary engineering goal. Use these guidelines to prioritize your selection criteria.

- If your primary focus is high-speed rotation: Prioritize a shaft with excellent surface finish and hardness, and select a PTFE compound with fillers that effectively manage and dissipate frictional heat.

- If your primary focus is aggressive chemical media: Your first step is to verify material compatibility with all potential process fluids, selecting a seal geometry that minimizes areas where chemicals could be trapped.

- If your primary focus is reliability across a wide pressure range: A spring-energized seal is often the best choice to ensure consistent lip contact from vacuum conditions to high-pressure spikes.

By treating the seal, shaft, and housing as a single engineered system, you can effectively leverage the unique advantages of PTFE for a reliable, long-lasting sealing solution.

Summary Table:

| Selection Factor | Key Consideration | Impact on Performance |

|---|---|---|

| Operating Temperature | Ambient and friction-generated heat | Affects PTFE's mechanical properties and wear rate |

| Rotational Speed | Peripheral velocity at the shaft surface | Drives frictional heat generation and wear |

| System Pressure | Operating pressure range | Influences sealing force and lip contact; may require spring energizer |

| Shaft Surface Finish | Smoothness (typically 8-16 µin Ra) and hardness | Critical for minimizing abrasive wear on the PTFE seal |

| Groove Dimensions | Precision machining and tolerances | Essential for correct seal support and installation without damage |

| Media Compatibility | Chemical resistance to primary and secondary fluids | Ensures material integrity and prevents seal degradation |

Optimize Your Sealing System with KINTEK's Expertise

Selecting the right PTFE rotary seal is a complex challenge that requires balancing performance, hardware, and environmental factors. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand that your application's success depends on a perfectly matched system. Our team provides expert guidance and custom fabrication services, from rapid prototyping to high-volume production, ensuring your seals deliver superior reliability and longevity.

Contact KINTEK today to discuss your specific requirements and leverage our precision manufacturing capabilities for your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers