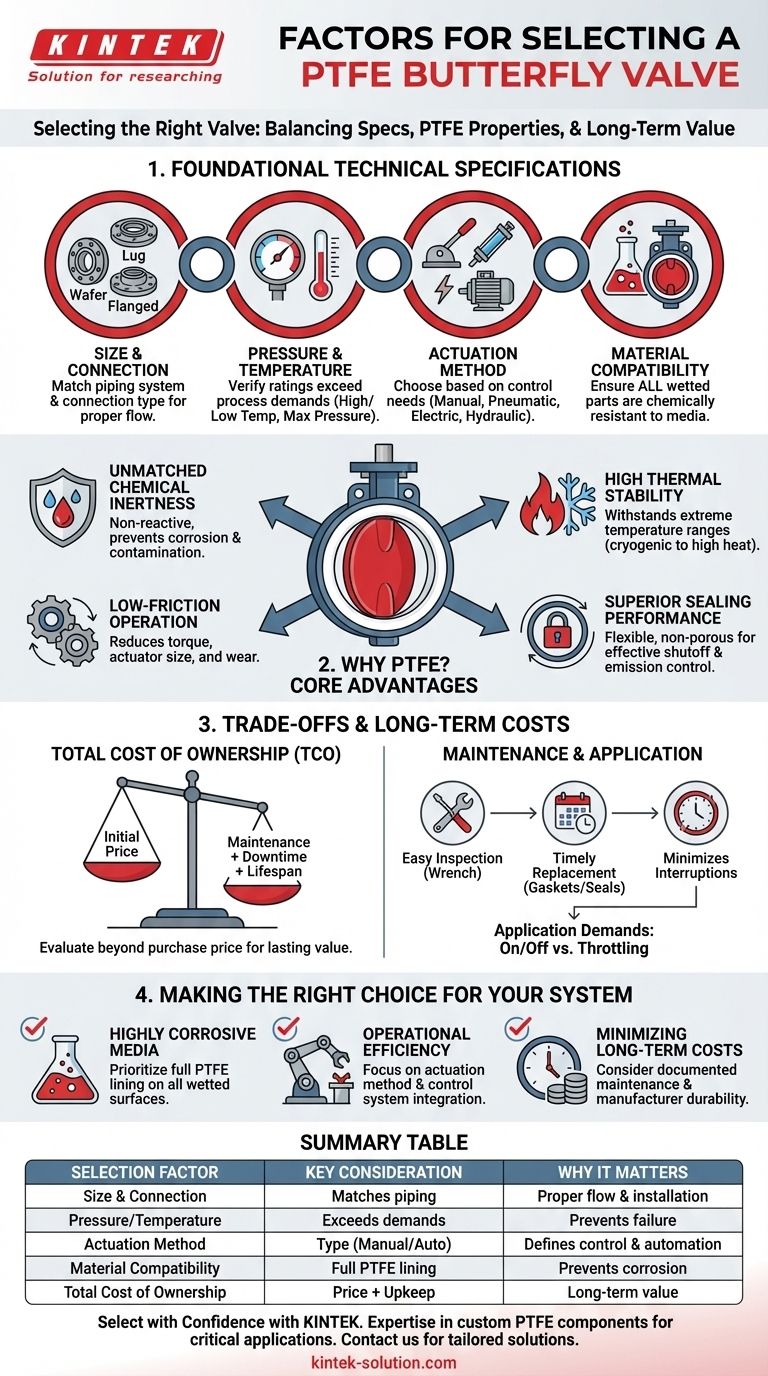

Selecting the right PTFE butterfly valve is a critical decision that hinges on matching the valve's capabilities to your system's specific demands. The process involves balancing five core technical specifications: proper sizing, pressure and temperature ratings, connection type, actuation method, and complete material compatibility with your process media.

The optimal choice goes beyond matching basic specifications on a data sheet. True success lies in understanding why PTFE is used—its unique chemical and physical properties—and evaluating the valve based on its total cost of ownership to ensure long-term system integrity and reliability.

The Foundational Technical Specifications

Before delving into the unique properties of PTFE, every valve selection must begin by confirming the fundamental mechanical and operational requirements. These factors ensure the valve can be physically and functionally integrated into your existing system.

Matching Size and Connection Type

The valve's nominal size must match your piping system to ensure proper flow characteristics without creating undue pressure drops. Equally important is the connection type—typically wafer, lug, or flanged—which dictates how the valve physically mounts between pipe sections.

Verifying Pressure and Temperature Ratings

Every valve has a defined operational envelope. You must confirm that the valve's maximum pressure and temperature ratings exceed the most demanding conditions of your process. Operating outside these limits can lead to catastrophic failure.

Choosing the Right Actuation Method

The method of opening and closing the valve depends on your control philosophy. Options range from simple manual levers or gear operators to automated systems using pneumatic, electric, or hydraulic actuators. The choice impacts response time, control precision, and system integration.

Ensuring Full Material Compatibility

This is the most critical checkpoint for a PTFE valve. You must verify that all wetted parts—not just the liner but also the disc and stem seals—are fully resistant to the chemicals in your process media. An oversight here can lead to rapid degradation and leaks.

Why PTFE? Understanding the Core Advantages

The reason PTFE-lined valves are specified for demanding applications is the material itself. Understanding these properties helps you appreciate the value beyond the basic specs and confirms if it's the right choice for your needs.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. This chemical inertness prevents it from reacting with process media, which is essential for preventing corrosion of the valve and contamination of the product.

High Thermal Stability

This material is capable of withstanding extreme temperature ranges, making it suitable for both high-heat processes and cryogenic applications. This stability ensures the valve maintains its structural integrity and sealing capability under thermal stress.

Low-Friction Operation

PTFE has an extremely low coefficient of friction. This property reduces the torque needed to open and close the valve, allowing for smaller, more efficient actuators. It also significantly reduces wear and tear on the sealing surfaces, enhancing the valve's longevity.

Superior Sealing Performance

The flexibility and non-porous nature of PTFE create a highly effective seal. This minimizes the risk of internal leaks when the valve is closed and prevents fugitive emissions from escaping into the atmosphere, which is critical for safety and environmental compliance.

Understanding the Trade-offs and Long-Term Costs

A truly informed decision looks beyond the initial purchase price and technical data. Evaluating the practical implications of ownership and maintenance is key to selecting a valve that provides lasting value.

The Importance of Total Cost of Ownership

The cheapest valve is rarely the most cost-effective. A comprehensive evaluation includes the initial cost plus anticipated expenses for maintenance, potential downtime, and replacement lifespan. A durable, reliable valve with minimal maintenance needs often presents a lower total cost over its lifetime.

Maintenance and Longevity

While PTFE's properties reduce wear, no valve is maintenance-free. A well-designed valve allows for easy inspection and timely replacement of components like gaskets and seals. Understanding these maintenance requirements is crucial for planning and minimizing process interruptions.

Application-Specific Demands

The intended function of the valve is a primary consideration. A valve used for simple on/off shutoff service has different requirements than one used for flow control or throttling, which demands greater precision and durability to handle partial-open positions.

Making the Right Choice for Your System

With a clear understanding of the technical, material, and long-term factors, you can make a selection that aligns perfectly with your primary operational goals.

- If your primary focus is handling highly corrosive media: Prioritize a design where all wetted surfaces are fully lined or encapsulated with a thick layer of high-grade PTFE.

- If your primary focus is operational efficiency and automation: The choice between pneumatic, electric, or hydraulic actuation and its compatibility with your control system becomes your most critical decision.

- If your primary focus is minimizing long-term costs and downtime: Look beyond the purchase price to the valve's documented maintenance requirements and the manufacturer's reputation for durability and support.

Ultimately, a methodical evaluation of both technical specifications and long-term operational needs will ensure your chosen valve becomes a reliable asset, not a recurring problem.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Size & Connection | Matches piping system (wafer, lug, flanged) | Ensures proper flow and easy installation |

| Pressure/Temperature | Must exceed process demands | Prevents catastrophic failure |

| Actuation Method | Manual, pneumatic, electric, hydraulic | Defines control precision and automation level |

| Material Compatibility | Full PTFE lining for all wetted parts | Prevents corrosion and product contamination |

| Total Cost of Ownership | Initial price + maintenance + lifespan | Determines long-term value and reliability |

Select with Confidence for Your Critical Applications

Choosing the right PTFE butterfly valve is essential for the integrity of your semiconductor, medical, laboratory, or industrial processes. KINTEK specializes in manufacturing high-precision PTFE components, including custom butterfly valves, seals, liners, and labware.

We understand that your success depends on unmatched chemical resistance, thermal stability, and long-term reliability. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a valve perfectly tailored to your specific media, pressure, and actuation requirements, minimizing your total cost of ownership.

Let our precision production and material science expertise work for you. Contact KINTEK today to discuss your valve needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications