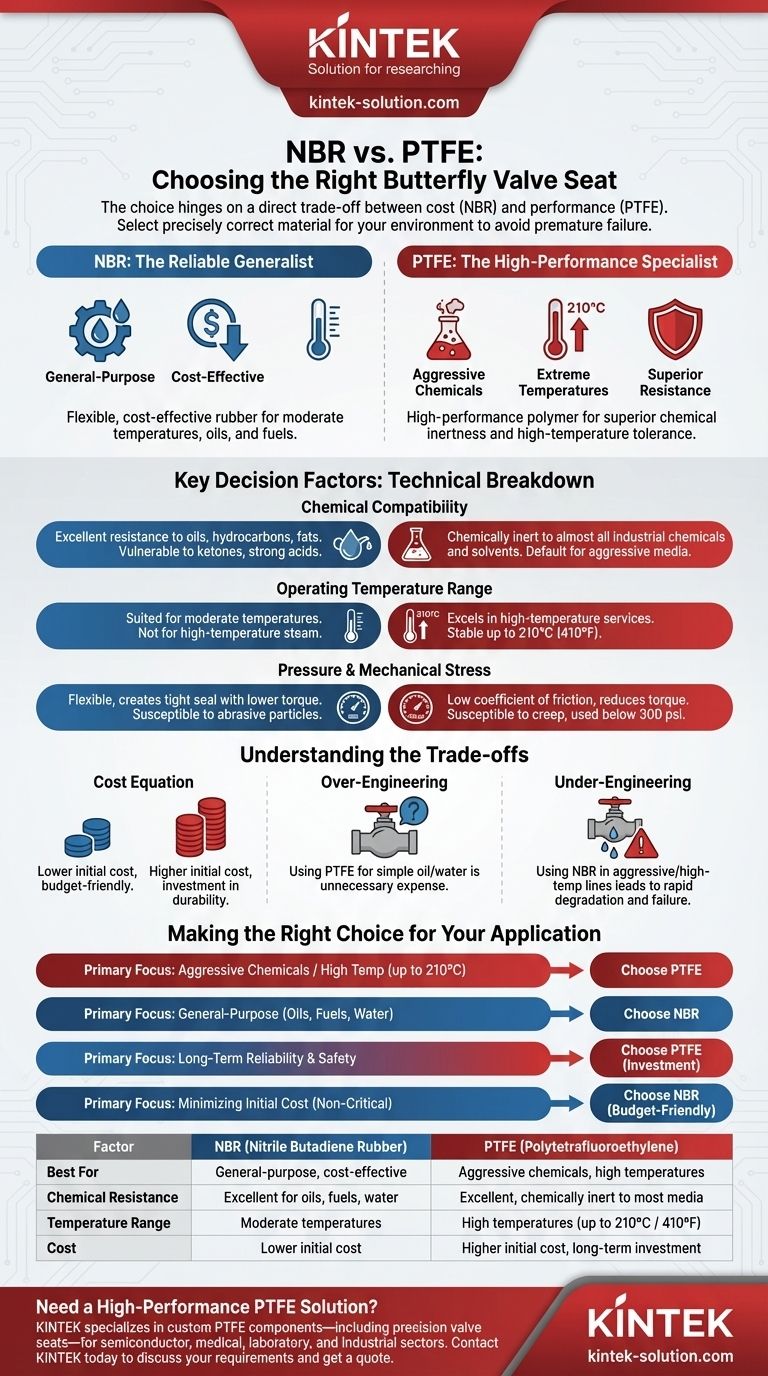

The choice between NBR and PTFE for a butterfly valve seat hinges on a direct trade-off between cost and performance. NBR is a flexible, cost-effective rubber ideal for general-purpose applications with moderate temperatures and exposure to oils. In contrast, PTFE is a high-performance polymer specified for its superior resistance to aggressive chemicals and extreme temperatures.

The decision is not about which material is universally "better," but which is precisely correct for your specific operational environment. Selecting the wrong seat material risks premature valve failure, leading to costly downtime and significant safety hazards.

The Fundamental Difference: Generalist vs. Specialist

Understanding the core nature of each material is the first step in making an informed decision. One is a versatile workhorse, while the other is a highly specialized solution for extreme conditions.

NBR: The Reliable Generalist

Nitrile Butadiene Rubber (NBR) is known for its excellent flexibility and sealing capability in moderate conditions. It offers very good resistance to oils, fuels, and other petroleum-based fluids.

Think of NBR as the reliable, all-purpose option for standard industrial applications where conditions are not overly demanding.

PTFE: The High-Performance Specialist

Polytetrafluoroethylene (PTFE) is engineered for environments where other materials would quickly fail. Its primary strengths are its near-universal chemical inertness and high-temperature tolerance.

PTFE is the specified material for aggressive chemical processing, pharmaceuticals, and any application involving corrosive media or elevated temperatures.

Key Decision Factors: A Technical Breakdown

Your choice must be driven by data. Analyze your system's operating parameters against the capabilities of each material.

Chemical Compatibility

This is the most critical factor. An incompatible material will degrade and cause the valve to fail.

PTFE is chemically inert to almost all industrial chemicals and solvents. It is the default choice for handling aggressive or mixed media.

NBR offers excellent resistance to oils, hydrocarbons, and fats but is vulnerable to ketones, halogenated hydrocarbons, and strong acids. Always verify compatibility with a chemical resistance chart.

Operating Temperature Range

A valve seat must maintain its integrity and sealing ability across the full operating temperature range of the system.

PTFE excels in high-temperature services, remaining stable at temperatures up to 210°C (410°F).

NBR is suited for moderate temperature ranges and is typically not recommended for applications involving high-temperature steam or fluids.

Pressure and Mechanical Stress

The valve seat must withstand the system pressure without deforming or extruding, a phenomenon known as creep.

PTFE has a low coefficient of friction, which reduces the torque needed to operate the valve and minimizes wear from abrasive media. However, it can be susceptible to creep and is typically used in systems below 300 psi.

NBR’s flexibility allows it to create a tight seal with lower torque, but it is more susceptible to physical damage from abrasive particles in the media.

Understanding the Trade-offs

Choosing a valve seat is an exercise in balancing performance requirements against project constraints.

The Cost Equation

There is a significant price difference between these materials. NBR is a far more budget-friendly option than PTFE.

The higher initial cost of a PTFE-seated valve is an investment in its durability and resistance to harsh conditions.

The Risk of Over-Engineering

Specifying a PTFE seat for a simple oil or water application is often an unnecessary expense. If the conditions fall well within NBR's capabilities, it can provide a perfectly reliable seal for a fraction of the cost.

The Danger of Under-Engineering

This is the most dangerous pitfall. Using an NBR seat in a chemically aggressive or high-temperature line will lead to rapid material degradation. The result is inevitable: leaks, process contamination, unscheduled shutdowns, and potential safety incidents.

Making the Right Choice for Your Application

To ensure optimal performance and longevity, match the material to the demands of your unique application.

- If your primary focus is handling aggressive chemicals or high temperatures (up to 210°C / 410°F): PTFE is the only reliable choice due to its chemical inertness and thermal stability.

- If your primary focus is a general-purpose application involving oils, fuels, or water in moderate conditions: NBR provides a highly effective and budget-friendly seal.

- If your primary focus is minimizing initial cost for a non-critical system: NBR offers the best balance of performance and affordability.

- If your primary focus is long-term reliability and safety in a harsh environment: The higher initial cost of PTFE is a necessary investment to prevent catastrophic failure.

Ultimately, a careful analysis of your specific operating media, temperature, and pressure is the only way to guarantee a safe, reliable, and cost-effective valve selection.

Summary Table:

| Factor | NBR (Nitrile Butadiene Rubber) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Best For | General-purpose, cost-effective applications | Aggressive chemicals, high temperatures |

| Chemical Resistance | Excellent for oils, fuels, water | Excellent, chemically inert to most media |

| Temperature Range | Moderate temperatures | High temperatures (up to 210°C / 410°F) |

| Cost | Lower initial cost | Higher initial cost, long-term investment |

Need a High-Performance PTFE Solution for Your Valves?

Selecting the right seat material is critical to preventing valve failure, costly downtime, and safety hazards. KINTEK specializes in manufacturing precision PTFE components—including custom valve seats—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet the exact demands of your application. Don't risk under-engineering your system.

Contact KINTEK today to discuss your specific requirements and get a quote for reliable, high-performance PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs