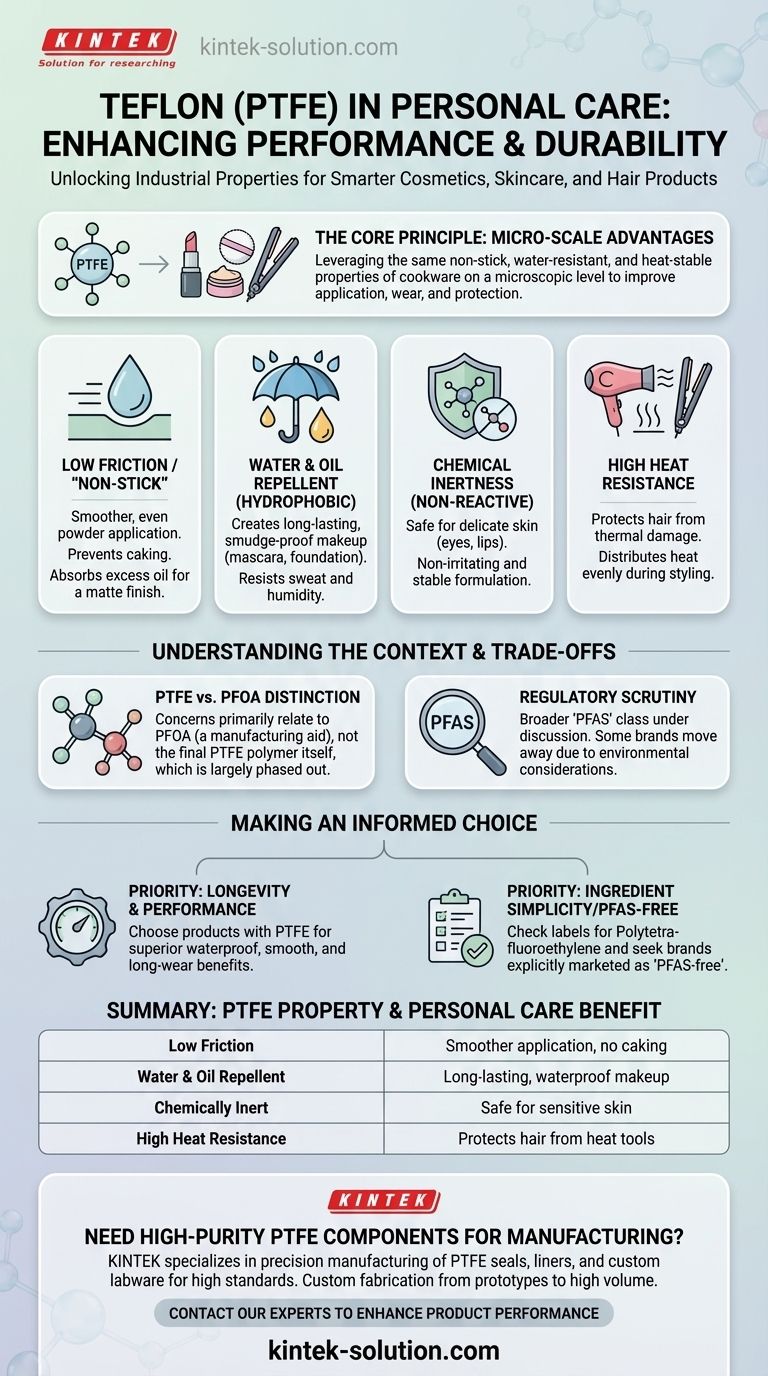

In the world of personal care, Teflon is used as a specialty ingredient in cosmetics, skincare, and hair products to enhance performance and durability. Under its chemical name Polytetrafluoroethylene (PTFE), it leverages its unique properties to make makeup last longer, powders feel smoother, and hair products protect against heat.

The core reason Teflon appears in personal care is simple: the same properties that make it an excellent non-stick coating for cookware—low friction, water resistance, and heat stability—are leveraged on a microscopic scale to improve the application, wear, and protective qualities of cosmetic products.

Why Teflon (PTFE) is in Your Personal Care Products

The use of PTFE in cosmetics is a direct application of its well-known industrial properties. Each characteristic serves a specific function in improving a product's formula.

The 'Non-Stick' Principle for a Flawless Finish

The most famous property of Teflon is its extremely low friction, which creates a non-stick surface.

In cosmetics like dusting powders, this translates to a smoother, more even application that resists caking. It helps absorb excess oil and sweat from the skin, maintaining a desirable matte finish.

Resisting Water and Oil for Longevity

Teflon is hydrophobic, meaning it repels water. This is critical for creating long-lasting makeup.

This property is used to make products like waterproof mascara, setting sprays, and foundations resistant to running or smudging from sweat or environmental moisture.

Chemical Inertness for Safety

A key attribute of PTFE is that it is non-reactive. It does not easily engage in chemical reactions with other substances, including human tissue.

This inertness makes it a safe ingredient for use on delicate facial tissues, such as the skin around the eyes and on the lips, without causing irritation.

Heat Resistance for Hair Protection

Teflon can withstand high temperatures without degrading, a property essential for modern hair care.

It is incorporated into certain hair products to provide a protective barrier, allowing for the safer use of hot styling tools like blow dryers and flat irons by distributing heat more evenly.

Understanding the Context and Trade-offs

While PTFE itself is considered stable and safe for topical use, its inclusion in consumer products is part of a larger conversation about a class of chemicals known as PFAS.

The Distinction Between PTFE and PFOA

The primary concerns often surround PFOA (Perfluorooctanoic acid), a chemical historically used in the manufacturing process of Teflon, not Teflon (PTFE) itself.

While the final PTFE polymer is stable, the manufacturing aids have faced scrutiny for their environmental persistence and potential health risks.

Regulatory Scrutiny and Industry Shifts

Due to these concerns, manufacturers have largely phased out the use of PFOA in favor of newer technologies.

However, the broader class of "per- and polyfluoroalkyl substances" (PFAS) continues to be a topic of regulatory discussion, prompting some brands to move away from these ingredients altogether in their formulations.

Making the Right Choice for Your Goal

Ultimately, understanding the function of PTFE helps you make an informed decision based on your priorities.

- If your primary focus is makeup longevity and performance: Products containing PTFE can offer superior waterproof, smudge-proof, and smooth-finish benefits.

- If your primary focus is ingredient simplicity or avoiding PFAS: You should check ingredient lists for Polytetrafluoroethylene (PTFE) and seek out brands that explicitly market themselves as "PFAS-free."

Understanding the science behind an ingredient list empowers you to select the products that best align with your personal standards and performance needs.

Summary Table:

| Property of Teflon (PTFE) | Benefit in Personal Care Products |

|---|---|

| Low Friction / Non-Stick | Smoother powder application, prevents caking |

| Water & Oil Repellent | Long-lasting, waterproof makeup (mascara, foundation) |

| Chemically Inert | Safe for sensitive skin, non-irritating |

| High Heat Resistance | Protects hair from heat-styling tools |

Need High-Purity PTFE Components for Your Personal Care or Cosmetic Manufacturing?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for industries that demand the highest standards of material performance and safety. Our expertise ensures that the PTFE used in your production process meets rigorous quality and purity requirements.

Whether you're developing a new cosmetic formula or scaling up production, we offer custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance your product performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support