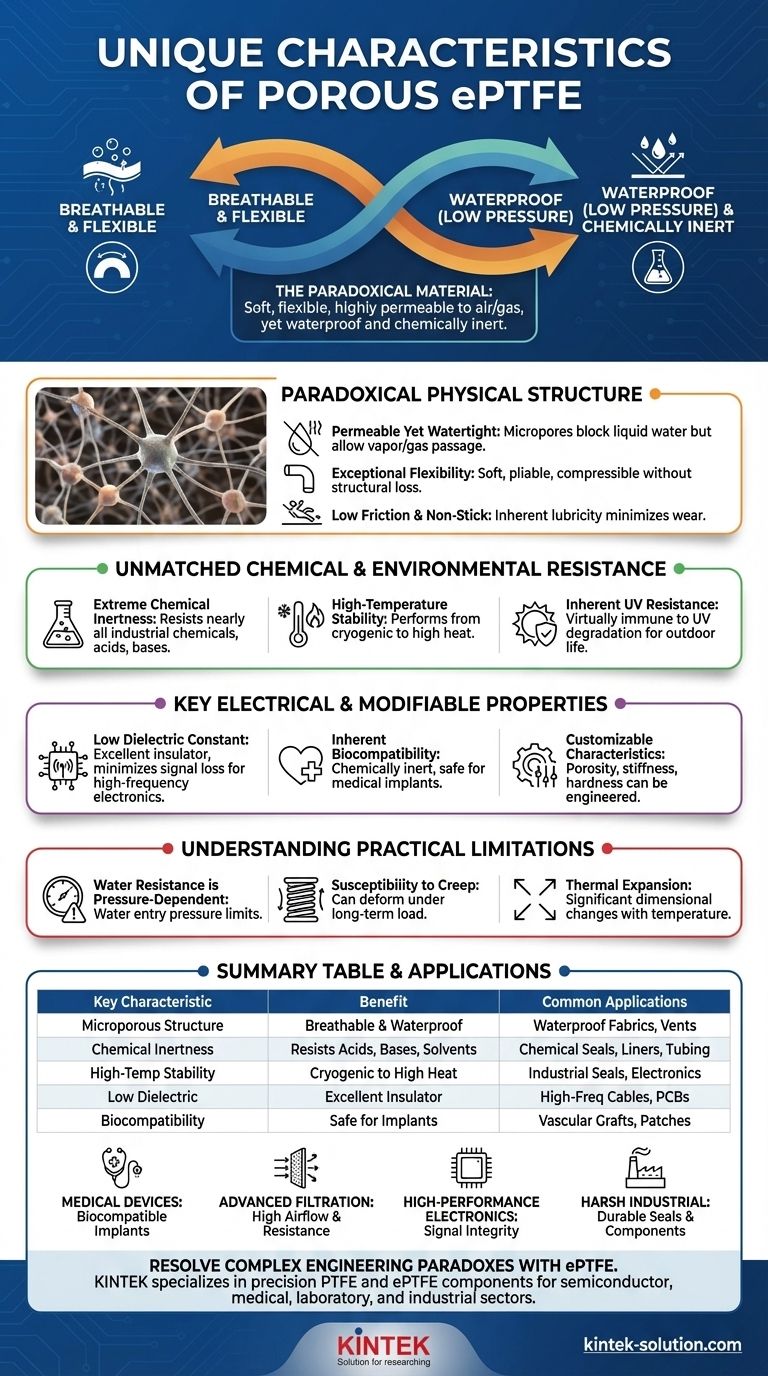

At its core, porous expanded Polytetrafluoroethylene (ePTFE) is defined by a unique combination of seemingly contradictory properties. It is a soft, flexible material that is highly permeable to air and gas, yet it remains waterproof under low pressure due to its microporous, hydrophobic structure. This, combined with its extreme chemical inertness and thermal stability, makes it one of the most versatile high-performance materials available.

The true defining characteristic of porous ePTFE is not a single attribute, but its ability to simultaneously provide solutions for opposing engineering challenges—such as the need for a material to be both breathable and waterproof, or both chemically inert and physically flexible.

The Paradoxical Physical Structure

The manufacturing process for ePTFE creates a unique microporous structure of nodes interconnected by fine fibrils. This internal architecture is the source of its most valuable physical characteristics.

Permeable Yet Watertight

The material's pores are small enough to block the passage of liquid water molecules due to high surface tension and hydrophobicity.

However, these same pores are large enough to allow smaller water vapor and other gas molecules to pass through freely. This property is the basis for its use in breathable, waterproof fabrics and advanced venting applications.

Exceptional Flexibility and Formability

Porous ePTFE is remarkably soft and pliable.

It can be collapsed longitudinally or compressed significantly without major changes to its external diameter or structural integrity. This makes it ideal for seals, gaskets, and medical implants that must conform to complex shapes.

Low Friction and Non-Stick Surface

Like all fluoropolymers, ePTFE has an extremely low coefficient of friction and non-stick characteristics.

This inherent lubricity minimizes wear in dynamic applications and prevents buildup in filtration or fluid transfer systems.

Unmatched Chemical and Environmental Resistance

ePTFE inherits the legendary durability of PTFE, allowing it to perform reliably in conditions where most other materials would quickly degrade.

Extreme Chemical Inertness

The material is chemically inactive and resists degradation from nearly all industrial chemicals, acids, and bases.

This makes it a premier choice for seals, tubing, and liners used in aggressive chemical processing and laboratory environments.

High-Temperature Stability

ePTFE maintains its properties across a very wide range of temperatures. It can withstand high heat without losing its structural integrity and remains flexible at cryogenic temperatures.

Inherent UV Resistance

Unlike many polymers, ePTFE is virtually immune to degradation from ultraviolet (UV) radiation. This ensures a long service life in outdoor applications without becoming brittle or weak.

Key Electrical and Modifiable Properties

Beyond its physical and chemical resilience, ePTFE offers distinct advantages in specialized fields like electronics and medicine, largely due to its adaptability.

Low Dielectric Constant

ePTFE has an exceptionally low dielectric constant, which means it is an excellent electrical insulator that stores very little electrical energy.

This property is critical for high-frequency electronics, such as coaxial cables and circuit boards, where it minimizes signal loss and ensures signal integrity.

Inherent Biocompatibility

The material is chemically inert and hydrophobic, which makes it highly biocompatible. The human body does not typically react to it, reducing the risk of rejection.

This has led to its widespread use in medical implants, including vascular grafts, surgical sutures, and soft tissue patches.

Customizable Characteristics

The ePTFE manufacturing process allows for precise control over its final properties.

Engineers can modify characteristics such as porosity, stiffness, surface energy, and hardness to meet the exact demands of a specific application.

Understanding the Practical Limitations

While ePTFE is a remarkable material, its properties come with important trade-offs that must be considered in any engineering design.

Water Resistance is Pressure-Dependent

The material is famously "watertight under low pressure." If the hydrostatic pressure exceeds the material's water entry pressure (WEP), liquid will be forced through the pores. This limit must be respected in any design.

Susceptibility to Creep

While highly resistant for a fluoropolymer, ePTFE can be subject to "creep" or "cold flow" over time, especially under high mechanical loads and elevated temperatures. Components under constant compressive force may slowly deform.

Thermal Expansion

Like its parent material PTFE, ePTFE has a relatively high coefficient of thermal expansion. Designs must account for dimensional changes across a wide operating temperature range to avoid stress or failure.

Making the Right Choice for Your Goal

Selecting ePTFE is about leveraging its unique combination of properties to solve a specific challenge that other materials cannot.

- If your primary focus is Medical Devices: Leverage its unmatched biocompatibility, chemical inertness, and controlled porosity for safe and effective implants.

- If your primary focus is Advanced Filtration or Venting: Capitalize on the microporous structure that perfectly balances high airflow with liquid and particulate resistance.

- If your primary focus is High-Performance Electronics: Utilize its extremely low dielectric constant and high-temperature stability to ensure signal integrity in demanding applications.

- If your primary focus is Harsh Industrial Environments: Depend on its extreme chemical resistance, low-friction surface, and wide operational temperature range for durable seals and components.

Ultimately, ePTFE's value lies in its power to resolve complex engineering paradoxes with a single, elegant material solution.

Summary Table:

| Key Characteristic | Benefit | Common Applications |

|---|---|---|

| Microporous Structure | Breathable & Waterproof (low pressure) | Waterproof Fabrics, Vents |

| Extreme Chemical Inertness | Resists Acids, Bases, Solvents | Chemical Seals, Liners, Tubing |

| High-Temperature Stability | Performs from Cryogenic to High Heat | Industrial Seals, Electronics |

| Low Dielectric Constant | Excellent Electrical Insulator | High-Frequency Cables, PCBs |

| Inherent Biocompatibility | Safe for Medical Implants | Vascular Grafts, Surgical Patches |

Need a high-performance material solution that balances seemingly contradictory properties like breathability and waterproofing?

KINTEK specializes in manufacturing precision PTFE and ePTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We leverage our expertise in custom fabrication, from prototypes to high-volume orders, to deliver components that meet your exact requirements for chemical resistance, thermal stability, and performance.

Contact KINTEK today to discuss how our porous ePTFE solutions can resolve your complex engineering challenges.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- How does PTFE behave in terms of chemical inertness? Unmatched Resistance for Demanding Applications

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware