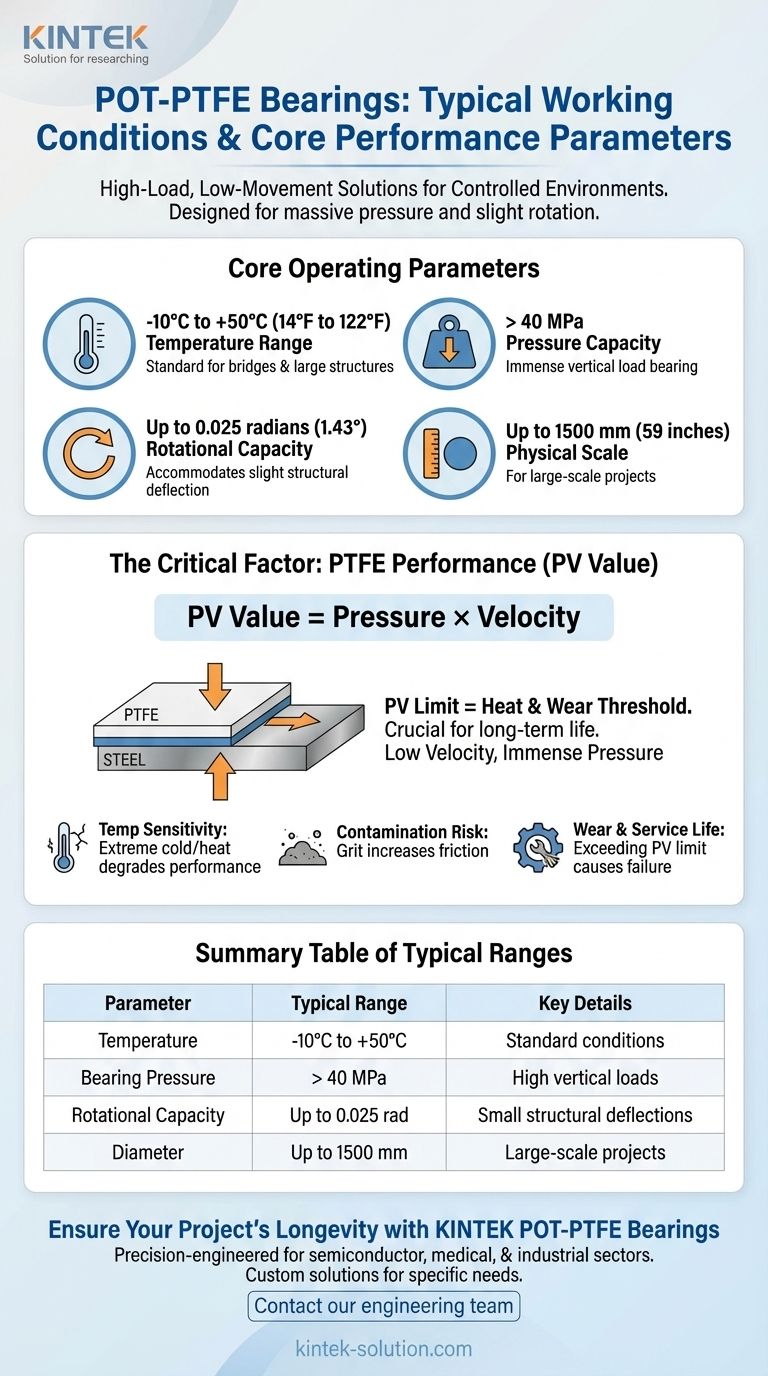

In short, a standard POT-PTFE bearing is designed for high-load, low-movement applications within a controlled environment. These bearings typically operate in a temperature range of -10°C to +50°C, accommodate rotations up to 0.025 radians, and can be manufactured in diameters up to 1500 mm. Depending on the specific PTFE filler material, they can withstand immense bearing pressures exceeding 40 MPa.

The core principle is that POT-PTFE bearings are engineered to manage immense pressure and slight rotational movements under specific environmental conditions. Their reliability hinges on respecting these operational limits to prevent premature wear on the critical PTFE surface.

Core Operating Parameters Defined

To properly specify or evaluate a POT-PTFE bearing, you must understand its primary operational boundaries. Each parameter defines a critical aspect of its performance and structural integrity.

Temperature Range

The standard operating temperature for these bearings is between -10°C and +50°C (14°F to 122°F). This range covers the vast majority of environmental conditions for structures like bridges and large buildings. Operating outside this range can compromise the material properties of the PTFE and elastomeric pad.

Load Capacity and Pressure

POT-PTFE bearings are designed for extremely high vertical loads. The ability to withstand pressures over 40 MPa (megapascals) is a key feature. This is made possible by the confined elastomeric pad in the steel "pot," which behaves like a fluid under pressure, allowing rotation without being crushed.

Rotational Capacity

These bearings are not meant for continuous or high-angle rotation. They are designed to accommodate the small, slow rotational movements caused by structural deflection under load. The typical limit of 0.025 radians (approximately 1.43 degrees) is sufficient for most large-scale structural applications.

Physical Scale

With diameters available up to 1500 mm (approx. 59 inches), these components are built for massive-scale projects. The size is directly related to the load it must bear and the displacement it needs to accommodate.

The Critical Factor: PTFE Performance

While the steel pot assembly handles the immense vertical load, the bearing's ability to allow for translation and low-friction rotation is entirely dependent on the Polytetrafluoroethylene (PTFE) layer.

Understanding PTFE's Behavior

PTFE, known for its extremely low coefficient of friction, performs best under moderate loads and slow speeds. It is not designed for high-velocity applications.

The Importance of the PV Value

In bearing design, the PV value (Pressure × Velocity) is a critical performance metric. It represents the combined effect of load and speed on the bearing surface. Every material has a maximum PV limit beyond which heat generation and wear increase dramatically.

Why This Matters in Practice

For a bridge bearing, the "velocity" is the slow speed of thermal expansion/contraction or structural deflection. While the speed is low, the pressure is immense. Manufacturers' guidelines on the PV value must be followed to prevent accelerated wear and ensure the bearing's long-term service life.

Understanding the Trade-offs and Limitations

No engineering component is without its limitations. Being aware of them is critical for ensuring long-term structural safety and performance.

Temperature Sensitivity

Operating outside the specified temperature range can cause issues. Extreme cold can make the PTFE more brittle, while excessive heat can lead to accelerated degradation and a potential loss of low-friction properties.

Contamination Risk

The low-friction performance of the PTFE surface is highly dependent on it being clean. The introduction of dust, grit, or chemical contaminants between the sliding surfaces can score the PTFE, increase friction, and impede movement.

Wear and Service Life

Exceeding the design limits, particularly the PV value, will cause the PTFE layer to wear out prematurely. This compromises the bearing's primary function of allowing controlled movement, which can transfer unintended stresses into the primary structure.

Making the Right Choice for Your Application

Selecting the correct bearing specification is fundamental to the health and longevity of the structure it supports.

- If your primary focus is a standard bridge or building in a temperate climate: The typical working parameters of a standard POT-PTFE bearing are almost certainly appropriate for your needs.

- If your primary focus is a structure in an extreme climate or with unusual movement requirements: You must consult directly with the manufacturer to explore specialized materials, such as modified PTFE fillers or different elastomers, to meet your specific design criteria.

Ultimately, understanding these operational boundaries is the first step in ensuring a structure can move as designed for decades to come.

Summary Table:

| Parameter | Typical Range | Key Details |

|---|---|---|

| Temperature | -10°C to +50°C | Standard environmental conditions for bridges and buildings. |

| Bearing Pressure | > 40 MPa | Designed for extremely high vertical loads. |

| Rotational Capacity | Up to 0.025 radians | Accommodates small structural deflections, not continuous rotation. |

| Diameter | Up to 1500 mm | Suitable for large-scale, massive projects. |

Ensure your project's longevity with precision-engineered POT-PTFE bearings from KINTEK.

Our expertise in manufacturing high-performance PTFE components, including seals and custom bearings, is critical for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production to meet your exact specifications, from prototypes to high-volume orders.

Let's discuss your specific application requirements and ensure your design operates within safe, reliable parameters.

Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability