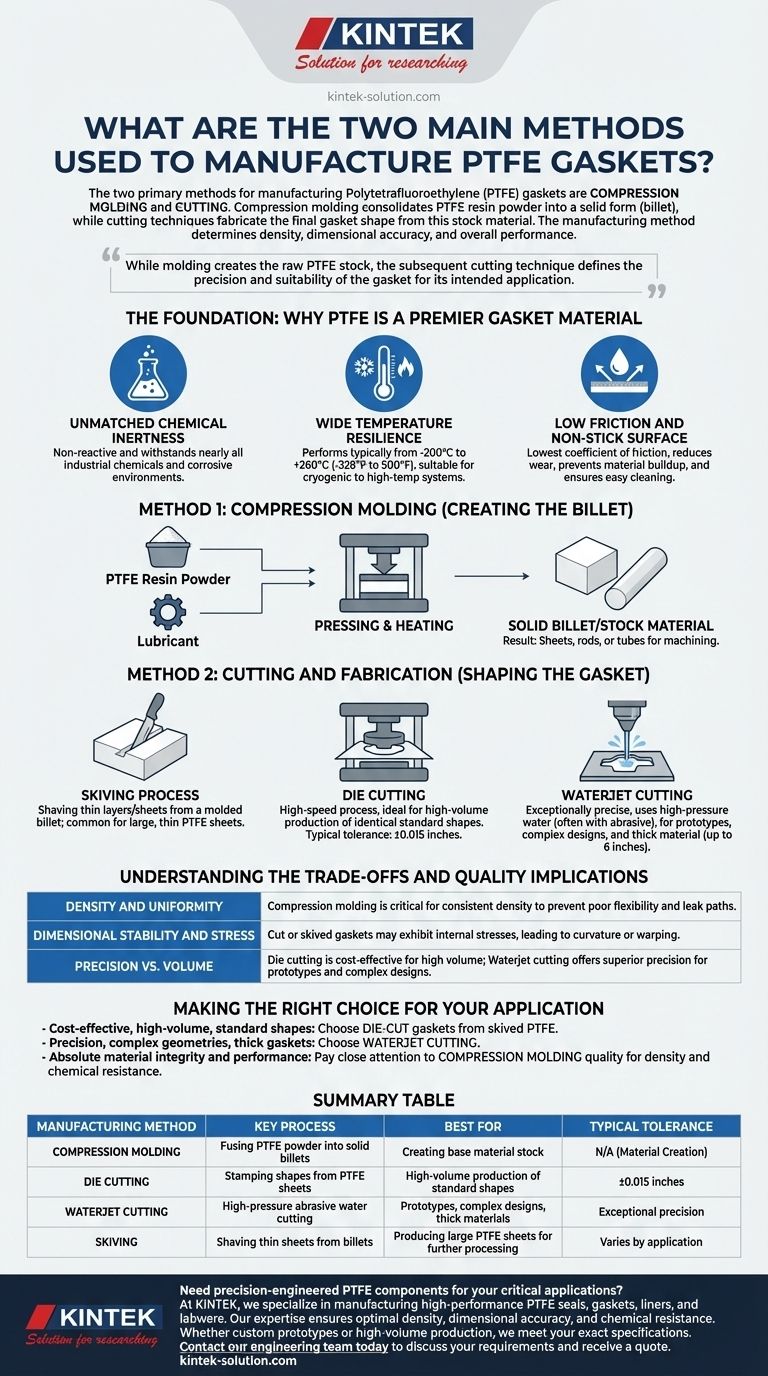

The two primary methods for manufacturing Polytetrafluoroethylene (PTFE) gaskets are compression molding and cutting. Compression molding involves consolidating PTFE resin powder into a solid form, like a sheet or rod, known as a billet. The cutting process, which includes techniques like skiving, die-cutting, and waterjet cutting, is then used to fabricate the final gasket shape from this pre-molded stock material.

The manufacturing method is not merely a production detail; it is the critical factor that determines the gasket's final density, dimensional accuracy, and overall performance. While molding creates the raw PTFE stock, the subsequent cutting technique defines the precision and suitability of the gasket for its intended application.

The Foundation: Why PTFE is a Premier Gasket Material

Before examining the manufacturing methods, it's essential to understand the inherent properties of PTFE that make it a sought-after material for sealing applications. The goal of any manufacturing process is to preserve these exceptional characteristics.

Unmatched Chemical Inertness

PTFE is non-reactive and withstands nearly all industrial chemicals and corrosive environments. This makes it an ideal choice for applications involving aggressive fluids where other materials would quickly degrade.

Wide Temperature Resilience

Standard PTFE gaskets perform reliably across an extreme temperature range, typically from -200°C to +260°C (-328°F to 500°F). This allows them to be used in everything from cryogenic processes to high-temperature systems.

Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick quality reduces wear and tear on system components, prevents material buildup, and ensures gaskets are easy to clean and service.

Method 1: Compression Molding (Creating the Billet)

Compression molding is the fundamental first step in creating the solid PTFE stock from which gaskets are made. This process dictates the base material's quality and internal structure.

The Molding Process Explained

The process begins by mixing fine PTFE resin powder, sometimes with a lubricant, and pressing it into a preform shape. This preform is then heated under immense pressure, causing the PTFE particles to fuse together into a solid, void-free block or cylinder known as a billet.

Primary Outcome: Stock Material

The direct output of compression molding is not the final gasket but the raw stock material. This can be in the form of sheets, rods, or tubes that will be machined or cut in a later step.

Method 2: Cutting and Fabrication (Shaping the Gasket)

Once a PTFE billet is created, the final gasket must be fabricated to precise dimensions. This is achieved through several cutting techniques.

The Skiving Process

Skiving is a technique where a thin layer or sheet of PTFE is "shaved" off a molded billet using a sharp blade. This is a common way to produce large, thin PTFE sheets from which gaskets can then be cut.

Technique Spotlight: Die Cutting

Die cutting is a high-speed process ideal for high-volume production. A sharp, custom-shaped tool (a die) is used to stamp out identical gaskets from a PTFE sheet. It is highly efficient and excellent for creating complex shapes with tight tolerances, often around ±0.015 inches.

Technique Spotlight: Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water, often mixed with an abrasive, to cut gaskets from PTFE sheets. This method is exceptionally precise, requires no custom tooling, and is capable of cutting very thick material—up to 6 inches—with excellent repeatability.

Understanding the Trade-offs and Quality Implications

The choice of manufacturing method has a direct impact on the quality and performance of the final gasket. It is crucial to understand these distinctions when specifying a product.

Density and Uniformity

The compression molding process is critical for ensuring consistent density throughout the PTFE stock. An improperly molded billet may have uneven density, leading to poor flexibility and potential leak paths in the final gasket.

Dimensional Stability and Stress

Gaskets cut or skived from a billet can sometimes exhibit internal stresses from the manufacturing process. This can result in a slight curvature or warping, which may complicate installation and require careful handling to ensure a proper seal.

Precision vs. Volume

Die cutting is the most cost-effective solution for producing thousands of identical parts quickly. However, waterjet cutting offers superior precision for prototypes, small batches, or intricate designs on thick materials where the cost of a custom die would be prohibitive.

Making the Right Choice for Your Application

Selecting the appropriate PTFE gasket requires matching the manufacturing method to your specific performance and operational needs.

- If your primary focus is cost-effective, high-volume production of standard shapes: Die-cut gaskets made from skived PTFE sheets offer the best balance of speed, material efficiency, and repeatability.

- If your primary focus is precision, complex geometries, or thick gaskets: Waterjet cutting provides unparalleled accuracy and design flexibility without the upfront cost of custom tooling.

- If your primary focus is absolute material integrity and performance: Pay close attention to the quality of the compression-molded billet, as this foundational step governs the gasket's final density and chemical resistance.

Understanding how a PTFE gasket is made is the first step to ensuring it performs exactly as you need it to.

Summary Table:

| Manufacturing Method | Key Process | Best For | Typical Tolerance |

|---|---|---|---|

| Compression Molding | Fusing PTFE powder into solid billets | Creating base material stock | N/A (Material Creation) |

| Die Cutting | Stamping shapes from PTFE sheets | High-volume production of standard shapes | ±0.015 inches |

| Waterjet Cutting | High-pressure abrasive water cutting | Prototypes, complex designs, thick materials | Exceptional precision |

| Skiving | Shaving thin sheets from billets | Producing large PTFE sheets for further processing | Varies by application |

Need precision-engineered PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, gaskets, liners, and labware for semiconductor, medical, laboratory, and industrial applications. Our expertise in both compression molding and precision cutting techniques ensures your components deliver optimal density, dimensional accuracy, and chemical resistance.

Whether you require custom prototypes or high-volume production, we deliver solutions that meet your exact specifications.

Contact our engineering team today to discuss your PTFE component requirements and receive a customized solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs