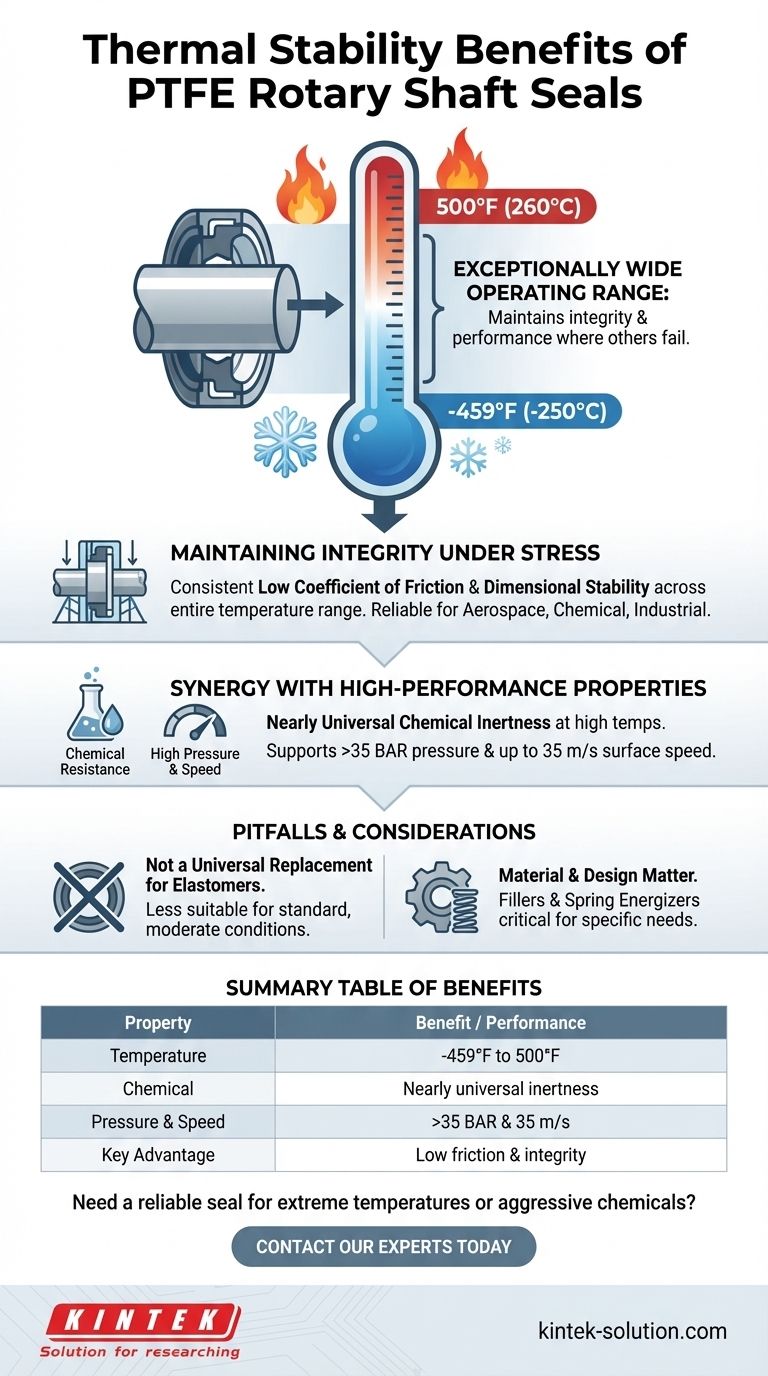

In short, the primary thermal benefit is an exceptionally wide operating temperature range. PTFE rotary shaft seals maintain their integrity and performance in conditions from cryogenic lows of -459°F (-250°C) to high-heat environments up to 500°F (260°C), where conventional elastomeric seals would fail.

The true value of PTFE's thermal stability is not just its resistance to temperature, but how this property works in concert with its chemical inertness and low-friction nature to enable reliable sealing in the most demanding industrial applications.

Why Thermal Stability is a Critical Advantage

The ability to withstand extreme temperatures is a foundational property of Polytetrafluoroethylene (PTFE). This characteristic allows for its use in applications that are simply impossible for many other sealing materials.

A Remarkably Wide Operating Range

PTFE can function effectively in both cryogenic applications and environments with intense heat. This dual capability makes it a uniquely versatile material for specialized industries.

Its performance is reliable across a spectrum from deep-freeze conditions to temperatures that would degrade or destroy most polymers.

Maintaining Integrity Under Stress

True thermal stability means more than just resisting melting or cracking. PTFE maintains its critical properties, such as its low coefficient of friction and dimensional stability, across this entire temperature range.

This ensures a consistent and reliable seal whether the application is in aerospace, chemical processing, or industrial manufacturing.

Synergy with Other High-Performance Properties

PTFE's thermal stability does not exist in isolation. It is a key part of a suite of high-performance characteristics.

The material is nearly universally inert to chemicals and solvents, meaning it can handle aggressive fluids even at high temperatures.

Furthermore, its ability to withstand high pressures (exceeding 35 BAR) and high surface velocities (up to 35 m/s) is directly supported by its thermal resilience.

Common Pitfalls and Considerations

While PTFE's properties are exceptional, understanding the context of its use is crucial for successful implementation. It is a specialized solution for demanding problems.

Not a Universal Replacement for Elastomers

PTFE seals are designed for conditions where traditional elastomeric (rubber) seals fail due to temperature, chemical attack, or high surface speeds.

For standard applications with moderate temperatures and pressures, elastomeric seals may offer different benefits, such as greater elasticity and lower cost, making them a more suitable choice.

Material Grade and Design Matter

The term "PTFE" can refer to virgin PTFE or filled compounds. Fillers are added to enhance properties like wear resistance or thermal conductivity.

The specific design of the seal, such as the inclusion of a spring energizer, is also critical for ensuring proper sealing force is maintained, especially in low-temperature or low-pressure situations.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is extreme temperatures (cryogenic or high-heat): PTFE is one of the few materials that can provide a reliable seal across such a vast thermal range.

- If your primary focus is aggressive chemical environments: PTFE's chemical inertness, combined with its thermal stability, makes it the default choice for sealing against corrosive fluids.

- If your primary focus is high-speed or high-pressure rotary systems: PTFE's low-friction, self-lubricating properties reduce heat generation and wear, ensuring seal longevity and performance.

Ultimately, choosing a PTFE seal is a decision to prioritize reliability and performance in environments where failure is not an option.

Summary Table:

| Property | Benefit / Performance |

|---|---|

| Operating Temperature Range | -459°F (-250°C) to 500°F (260°C) |

| Chemical Resistance | Nearly universal inertness to aggressive fluids |

| Pressure & Speed | Withstands >35 BAR pressure & up to 35 m/s surface speeds |

| Key Advantage | Maintains low friction & integrity across the entire thermal range |

Need a reliable seal for extreme temperatures or aggressive chemicals?

PTFE's exceptional thermal stability is crucial for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—that deliver precision and reliability from prototype to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications