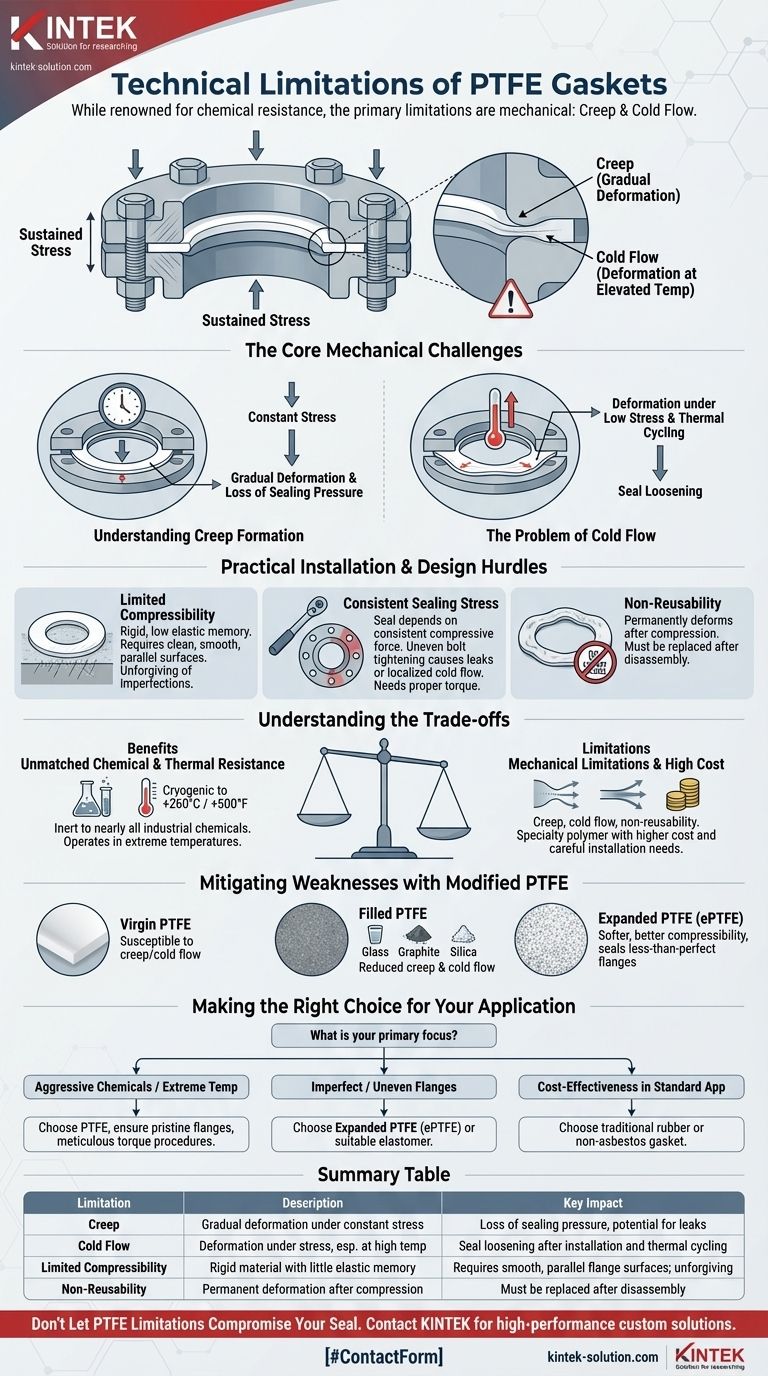

While renowned for its exceptional chemical resistance, the primary technical limitations of Polytetrafluoroethylene (PTFE) gaskets are not chemical but mechanical. These gaskets are highly susceptible to creep (gradual deformation under sustained stress) and cold flow (deformation at elevated temperatures), which can lead to a loss of sealing pressure over time. Furthermore, their limited compressibility makes them less forgiving of imperfect or uneven flange surfaces compared to traditional elastomeric gaskets.

The core challenge with PTFE gaskets lies in their physical behavior, not their material composition. While nearly invincible chemically, their tendency to deform under pressure requires precise installation, perfectly prepared surfaces, and an understanding of their mechanical limits to ensure a reliable, long-term seal.

The Core Mechanical Challenges: Creep and Cold Flow

The most significant limitations of PTFE gaskets stem from the material's inherent tendency to change shape under mechanical load, a behavior that can compromise the integrity of a sealed joint.

Understanding Creep Formation

Creep is the gradual deformation of the gasket material when subjected to long-term, constant stress, such as the pressure from a bolted flange.

Over time, this slow deformation causes the gasket to thin out, reducing the bolt load and the overall sealing pressure on the flange. This can eventually lead to leaks without any external changes to the system.

The Problem of Cold Flow

Cold flow is a similar phenomenon but describes PTFE's tendency to deform under relatively low stress, particularly as temperatures rise.

Even within its approved operating temperature range, the material can "flow" away from the point of highest pressure. This makes maintaining consistent bolt torque a critical challenge, as the seal can loosen after initial installation and thermal cycling.

Practical Installation and Design Hurdles

Beyond long-term material behavior, PTFE presents immediate challenges during installation that must be properly managed.

Limited Compressibility

Unlike rubber or other elastomers that have significant "springiness," PTFE is a more rigid material. It has very little elastic memory.

This means it cannot easily conform to scratches, pits, or other imperfections on a flange face. A successful seal with PTFE requires clean, smooth, and perfectly parallel flange surfaces.

The Need for Consistent Sealing Stress

Because PTFE lacks the elastic recovery of rubber, achieving a seal is entirely dependent on applying and maintaining a consistent compressive force.

Uneven bolt tightening can create high- and low-pressure zones, leading to leaks or localized cold flow. This necessitates the use of proper torque procedures and patterns during assembly.

Non-Reusability

Once a PTFE gasket is compressed, it deforms permanently. It takes a "set" and will not return to its original shape.

For this reason, a PTFE gasket should never be reused after the flange has been disassembled. It must be replaced to ensure a reliable seal.

Understanding the Trade-offs

The mechanical limitations of PTFE do not exist in a vacuum. They are the trade-off for a set of benefits that are unmatched by almost any other polymer.

Unmatched Chemical and Thermal Resistance

The reason engineers specify PTFE despite its challenges is its extraordinary resilience. It is inert to nearly all industrial chemicals and can operate efficiently in temperatures from cryogenic levels up to +260°C (+500°F).

For applications involving highly corrosive media or extreme temperatures where elastomers would fail, PTFE is often the only viable choice.

Mitigating Weaknesses with Modified PTFE

To address the inherent mechanical weaknesses of virgin PTFE, manufacturers have developed enhanced versions.

Filled PTFE incorporates materials like glass, graphite, or silica to reduce creep and cold flow. Expanded PTFE (ePTFE) is a softer, more flexible form that offers much better compressibility, allowing it to seal less-than-perfect flanges effectively.

The Cost Factor

PTFE is a specialty polymer, and its manufacturing process makes it significantly more expensive than common rubber gasket materials.

This higher cost, combined with the need for careful handling and installation, makes it an engineered solution rather than a general-purpose gasket.

Making the Right Choice for Your Application

Selecting the right gasket requires balancing the chemical and thermal demands of the application against the mechanical realities of the sealing surfaces.

- If your primary focus is sealing aggressive chemicals or extreme temperatures: PTFE is an excellent choice, but you must ensure your flanges are pristine and use meticulous bolt torque procedures to prevent creep.

- If you are dealing with imperfect, worn, or uneven flanges: Virgin PTFE will likely fail. You should specify a more conformable material like expanded PTFE (ePTFE) or a suitable elastomer.

- If your primary focus is cost-effectiveness in a standard application: PTFE is likely overkill. A traditional rubber or non-asbestos gasket will provide a reliable seal at a much lower cost.

By understanding these mechanical behaviors, you can engineer your system to leverage PTFE's exceptional resistance while avoiding common sealing failures.

Summary Table:

| Limitation | Description | Key Impact |

|---|---|---|

| Creep | Gradual deformation under constant stress | Loss of sealing pressure over time, potential for leaks |

| Cold Flow | Deformation under stress, especially at high temperatures | Seal loosening after installation and thermal cycling |

| Limited Compressibility | Rigid material with little elastic memory | Requires smooth, parallel flange surfaces; unforgiving of imperfections |

| Non-Reusability | Permanent deformation after compression | Must be replaced after flange disassembly |

Don't Let PTFE Limitations Compromise Your Seal

Understanding the mechanical behaviors of PTFE is crucial for a successful application. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets, seals, and liners. Our expertise ensures you get a solution engineered to handle creep, cold flow, and your specific operational demands—whether you're in the semiconductor, medical, laboratory, or industrial sector.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to maximize the benefits of PTFE's chemical and thermal resistance while mitigating its weaknesses.

Contact us today to discuss your sealing challenges and let our experts provide a reliable, durable solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech