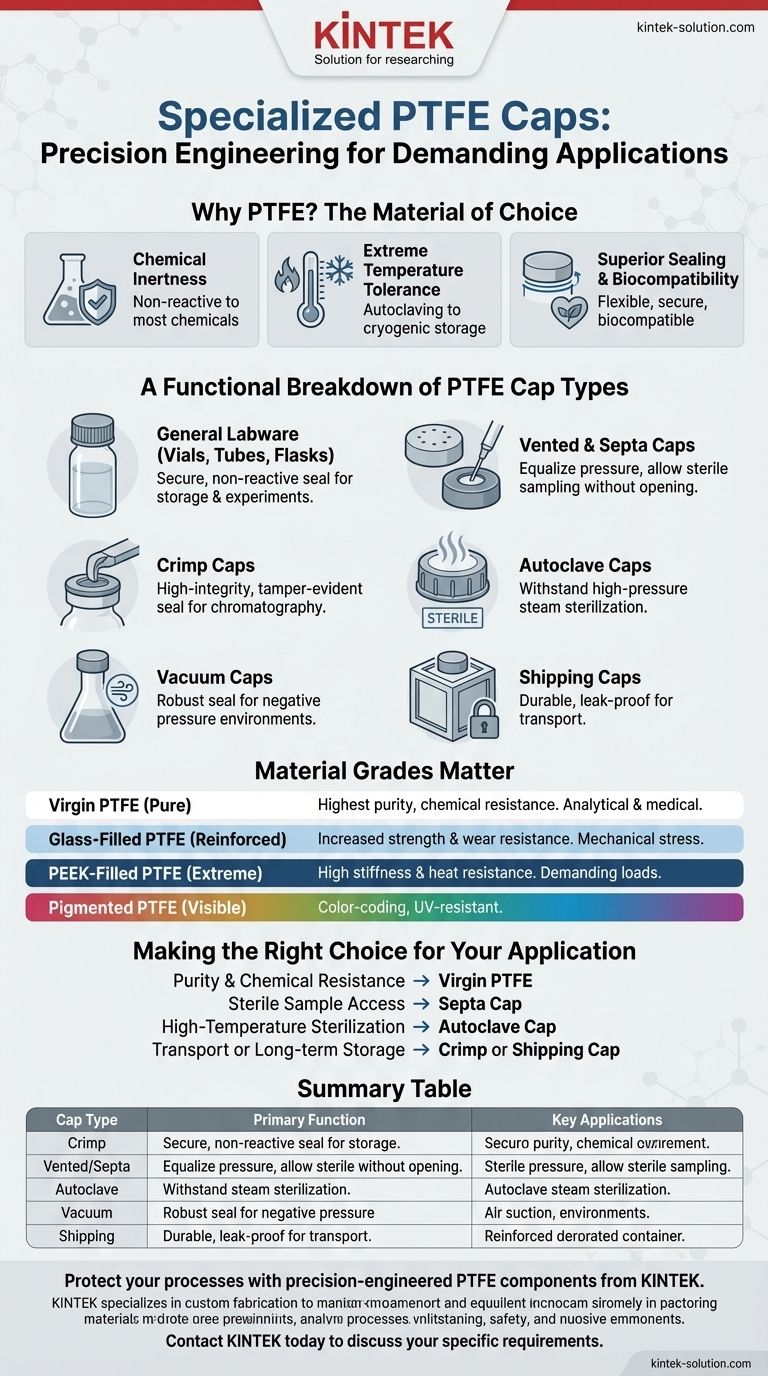

Beyond a simple lid, specialized PTFE caps are precision-engineered components designed to solve specific challenges in laboratory, industrial, and medical settings. The primary types include crimp, vial, tube, flask, shipping, autoclave, vacuum, and vented or septa caps, each created to ensure sample integrity, chemical compatibility, and safety under demanding conditions like high temperatures, sterilization, or transport.

The key is to understand that the type of PTFE cap is defined by its function, not just its shape. Choosing the right cap involves matching its specific design—such as its sealing mechanism or venting capability—to the precise demands of your application, from high-pressure sterilization to sterile sampling.

Why PTFE is the Material of Choice for Specialized Caps

Polytetrafluoroethylene (PTFE) is not just a non-stick coating. Its unique combination of properties makes it an ideal material for high-performance sealing applications where purity and reliability are non-negotiable.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it will not react with the vast majority of chemicals, acids, and bases. This makes it essential for storing or analyzing sensitive substances without risk of contamination from the cap itself.

Extreme Temperature Tolerance

This material maintains its integrity and sealing properties across a vast temperature range. This is critical for applications involving autoclaving (high-heat sterilization) or cryogenic storage.

Superior Sealing and Biocompatibility

PTFE's flexibility and low coefficient of friction allow it to create a tight, reliable seal. Furthermore, its inherent biocompatibility means it is safe for medical and biological applications, as it does not cause adverse reactions in living tissue.

A Functional Breakdown of PTFE Cap Types

Each specialized cap is designed to perform a specific task reliably. Understanding their purpose is key to selecting the correct one.

Caps for General Labware (Vials, Tubes, Flasks)

These are the most common types, designed to provide a secure, non-reactive seal for general laboratory experiments and sample storage. Their primary goal is to prevent contamination and evaporation.

Vented & Septa Caps for Sampling

Vented caps are designed to equalize pressure, preventing container collapse or rupture when contents outgas or temperature changes occur. Septa caps feature a pierceable membrane, allowing a needle to withdraw a sample without opening the container, maintaining sterility.

Crimp Caps for High-Integrity Sealing

Used extensively in chromatography and analytics, crimp caps are applied with a special tool to create a tamper-evident, high-integrity seal. This ensures that the sample is perfectly contained and has not been compromised.

Autoclave Caps for Sterilization

These caps are specifically engineered to withstand the high-temperature, high-pressure steam environment of an autoclave. They are often designed to vent slightly during the process to prevent pressure buildup while maintaining a sterile barrier.

Vacuum Caps for Low-Pressure Environments

When working under negative pressure, a standard cap can leak or fail. Vacuum caps are designed with a more robust sealing mechanism to maintain a tight seal and prevent air from entering the container.

Shipping Caps for Transport

Designed for durability, these caps provide a robust, leak-proof seal to ensure the integrity and safety of sensitive substances during transport. They are often built to withstand vibration and temperature fluctuations.

Understanding the Trade-offs: Material Grades Matter

Not all PTFE is the same. The grade of the material impacts the cap's performance, and choosing the wrong one can compromise your work.

Virgin PTFE for Ultimate Purity

Virgin (unfilled) PTFE is the purest form, offering the highest level of chemical resistance and electrical insulation. It is the default choice for most high-purity analytical and medical applications.

Glass-Filled PTFE for Strength

Reinforcing PTFE with glass fibers significantly increases its strength, stiffness, and wear resistance. This grade is used when the cap must withstand mechanical stress, though it may be less suitable for highly reactive chemicals that can attack glass.

PEEK-Filled PTFE for Extreme Conditions

Combining PTFE with PEEK (Polyetheretherketone) creates a composite with exceptionally high stiffness and wear resistance. These caps are reserved for the most demanding applications involving high mechanical loads and temperatures.

Pigmented PTFE for Visibility

For applications requiring color-coding or easy identification, pigments can be added to the PTFE. These are typically UV-resistant and are chosen to be as inert as possible to minimize any potential contamination.

Making the Right Choice for Your Application

Selecting the correct cap is a critical step in ensuring the success and safety of your work. Your choice should be guided by the primary goal of your task.

- If your primary focus is sample purity and chemical resistance: Choose caps made from Virgin PTFE for general lab use, storage, and analysis.

- If your primary focus is repeated, sterile sample access: Select a septa cap to allow for needle piercing without compromising container integrity.

- If your primary focus is high-temperature sterilization: You must use specifically designed Autoclave caps that can withstand steam and pressure.

- If your primary focus is transport or long-term storage: Crimp caps or dedicated Shipping caps offer the highest and most reliable seal integrity.

Choosing the right specialized PTFE cap is a crucial decision that protects the integrity of your work from start to finish.

Summary Table:

| Cap Type | Primary Function | Key Applications |

|---|---|---|

| Crimp Caps | High-integrity, tamper-evident seal | Chromatography, sample analysis |

| Vented/Septa Caps | Pressure equalization; sterile sampling | Cell culture, reactions with outgassing |

| Autoclave Caps | Withstand high-pressure steam sterilization | Medical, pharmaceutical, and biological labs |

| Vacuum Caps | Maintain seal under negative pressure | Vacuum filtration, degassing |

| Shipping Caps | Leak-proof seal for transport | Safe transport of sensitive materials |

Protect your processes with precision-engineered PTFE components from KINTEK.

Whether your application demands the ultimate purity of virgin PTFE for sensitive analysis or the reinforced strength of glass-filled PTFE for demanding environments, KINTEK has the solution. We specialize in manufacturing high-quality PTFE caps, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your specific requirements and ensure the integrity of your work.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications