In short, Teflon (PTFE) balls are recommended for applications where chemical resistance, temperature stability, and low friction are critical, but high mechanical strength is not. They are commonly used in fluid handling equipment like valves and pumps, low-load bearings, and in high-purity environments such as medical devices and food processing.

The decision to use a Teflon ball is rarely about its strength. Instead, it is a strategic choice for environments where chemical inertness, self-lubrication, and resistance to extreme temperatures are the most important design requirements.

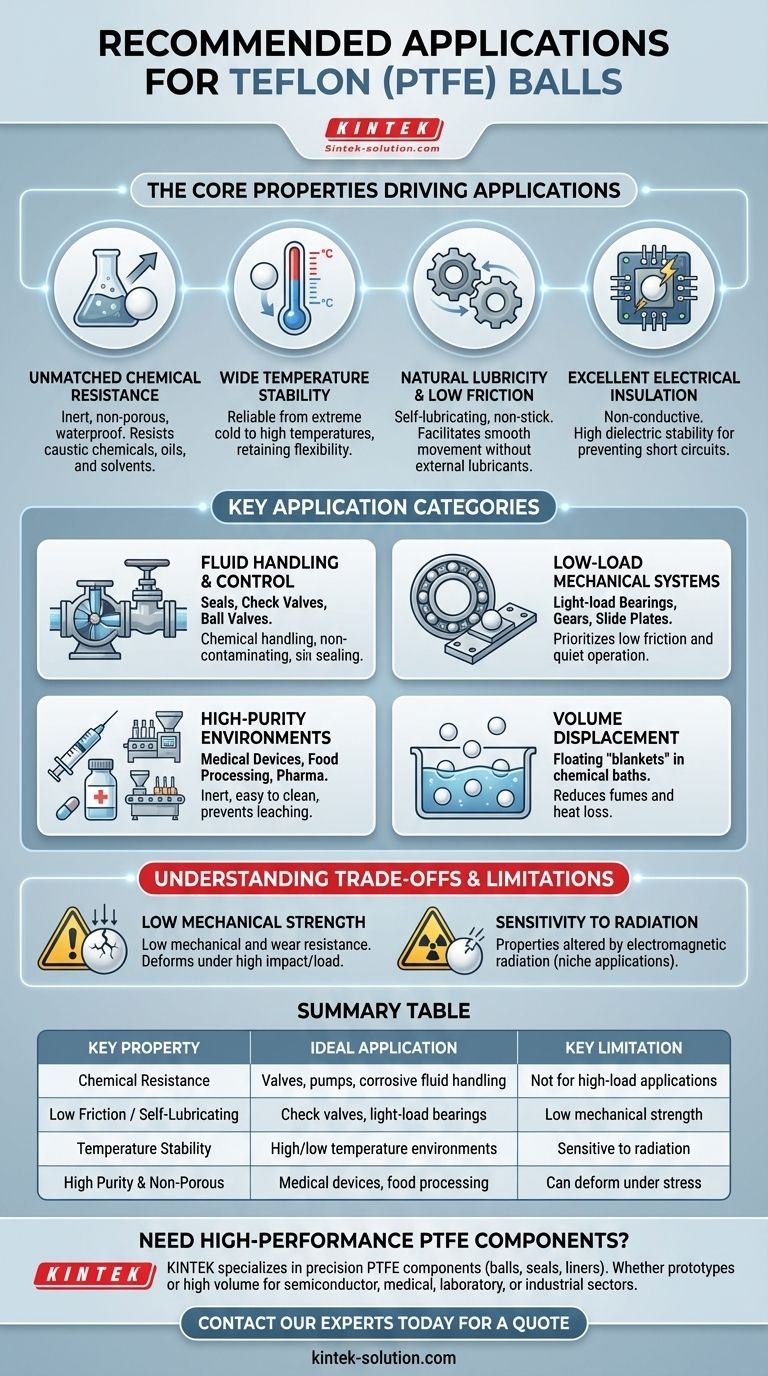

The Core Properties Driving Teflon Ball Applications

To understand where to use Teflon balls, you must first understand their defining characteristics. These properties make them uniquely suited for specific tasks and entirely wrong for others.

Unmatched Chemical Resistance

Teflon is exceptionally inert, meaning it does not react with most chemicals. This makes it a premier choice for components that will be in constant contact with corrosive or sensitive fluids.

It is waterproof, non-porous, and resists damage from caustic chemicals, oils, and solvents, ensuring the integrity of both the ball and the medium it touches.

Wide Temperature Stability

PTFE balls perform reliably across a broad temperature spectrum. They can handle high-temperature applications in industrial processing and also retain their flexibility at very low temperatures.

This thermal stability makes them dependable in environments with significant temperature fluctuations where other plastics might fail.

Natural Lubricity and Low Friction

Teflon is famous for its non-stick, or self-lubricating, properties. This inherent lubricity means Teflon balls can facilitate smooth movement in mechanical systems without requiring external lubricants.

This is ideal for check valves, which must open and close freely, and for low-load bearings where minimizing friction is key.

Excellent Electrical Insulation

As a material, Teflon does not conduct electricity. Its high dielectric stability makes it an effective insulator.

This property is leveraged in electrical and electronic components where parts must be electrically isolated from each other to prevent short circuits.

Key Application Categories Explained

The properties of Teflon directly translate into its most common and effective applications.

Fluid Handling and Control

This is Teflon's primary domain. Its chemical inertness and ductility make it an excellent material for seals, check valves, and ball valves.

In a chemical handling pump, a Teflon ball will not corrode or contaminate the product being moved. As a valve component, it creates a reliable seal and operates smoothly.

Low-Load Mechanical Systems

Due to its self-lubricating nature, Teflon is used in light-load bearings, gears, and slide plates.

The key term here is "light-load." These applications prioritize low friction and quiet operation over the ability to withstand significant force or impact.

High-Purity Environments

The purity and non-porous surface of Teflon make it ideal for medical devices, pharmaceutical manufacturing, and food processing equipment.

Because it is inert and easy to clean, it will not leach chemicals into the product or harbor contaminants, which is a critical requirement in these regulated industries.

Volume Displacement

In chemical baths and other industrial processes, Teflon balls are often used for volume displacement.

Their light weight and resistance to the chemicals in the bath allow them to act as a floating "blanket" on the liquid's surface, reducing fumes and heat loss without reacting with the solution.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging Teflon's weaknesses is crucial for making an informed decision.

Low Mechanical Strength

This is the most significant limitation of Teflon. Compared to other engineering plastics and especially metals, PTFE has low mechanical and wear resistance.

It should never be used in high-load bearings or in applications where it will be subjected to high impact or abrasive forces. It will deform and wear out quickly under such stress.

Sensitivity to Radiation

The properties of Teflon can be altered when exposed to certain types of electromagnetic radiation.

This is a niche but important consideration for applications in specific scientific, nuclear, or space-related fields where such radiation is present.

Making the Right Choice for Your Application

Use these guidelines to determine if Teflon balls are the correct component for your project.

- If your primary focus is corrosion and contamination control: Use Teflon balls in pumps, valves, and food/medical devices where chemical inertness is paramount.

- If your primary focus is low-friction, self-lubricating movement: They are an excellent choice for light-load bearings and check valves that must operate without external lubrication.

- If your primary focus is high load or structural strength: You must look for alternative materials like steel, ceramic, or other engineering plastics, as Teflon is not suitable.

- If your primary focus is electrical isolation: Their dielectric properties make them a solid option for insulating components in electronic assemblies.

By understanding both the strengths and weaknesses of Teflon, you can confidently select the right material for your specific engineering challenge.

Summary Table:

| Key Property | Ideal Application | Key Limitation |

|---|---|---|

| Chemical Resistance | Valves, pumps, corrosive fluid handling | Not for high-load applications |

| Low Friction / Self-Lubricating | Check valves, light-load bearings | Low mechanical strength |

| Temperature Stability | High/low temperature environments | Sensitive to radiation |

| High Purity & Non-Porous | Medical devices, food processing, pharmaceuticals | Can deform under stress |

Need High-Performance PTFE Components?

KINTEK specializes in manufacturing precision PTFE components, including balls, seals, liners, and custom labware. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we deliver the chemical resistance, purity, and reliability your application demands.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments