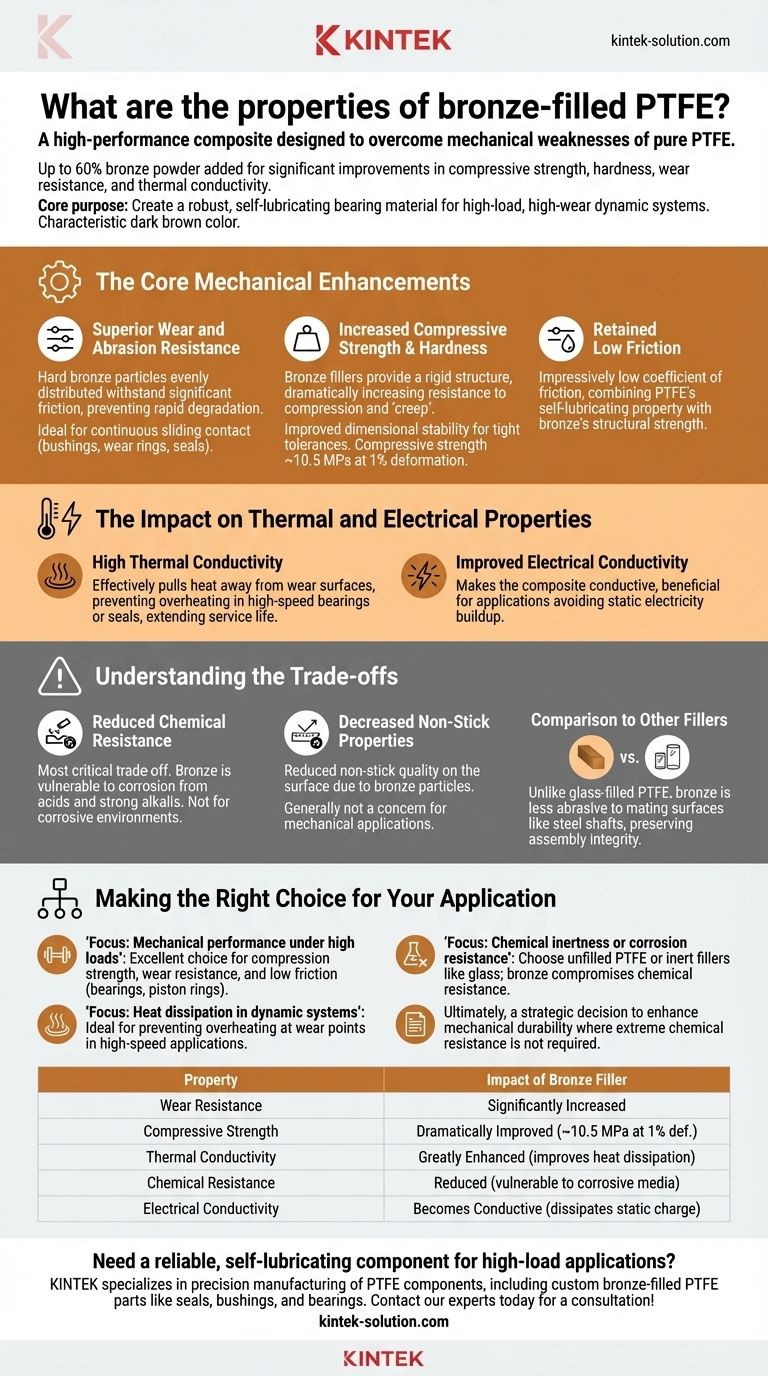

In short, bronze-filled PTFE is a high-performance composite designed to overcome the mechanical weaknesses of pure PTFE. By adding up to 60% bronze powder, the material gains significant improvements in compressive strength, hardness, wear resistance, and thermal conductivity, making it suitable for demanding mechanical applications. Its defining characteristic is its dark brown color.

The core purpose of adding bronze to PTFE is to create a robust, self-lubricating bearing material. It sacrifices the chemical inertness of pure PTFE to gain the strength and heat dissipation needed for high-load, high-wear dynamic systems.

The Core Mechanical Enhancements

Adding bronze particles fundamentally changes the mechanical behavior of PTFE, turning a soft polymer into a durable engineering material.

Superior Wear and Abrasion Resistance

The hard bronze particles are evenly distributed within the softer PTFE matrix. This composition creates a material that can withstand significant friction and abrasion without rapid degradation.

This makes it an ideal choice for components that experience continuous sliding contact, such as bushings, wear rings, and seals.

Increased Compressive Strength & Hardness

Pure PTFE is notoriously soft and prone to "creep" or deform under sustained load. Bronze fillers provide a rigid internal structure, dramatically increasing the material's ability to resist compression and maintain its shape.

This improved dimensional stability is critical for maintaining tight tolerances in components like bearings and piston rings, where even minor deformation can lead to failure. It has a compressive strength of around 10.5 MPa at just 1% deformation.

Retained Low Friction

While not as low as pure PTFE, the composite retains an impressively low coefficient of friction. The PTFE provides the self-lubricating property, while the bronze provides the structural strength to support the load.

The Impact on Thermal and Electrical Properties

The metallic nature of the bronze filler introduces properties that are entirely absent in pure PTFE.

High Thermal Conductivity

One of the most significant advantages is its ability to conduct heat. In high-speed bearings or seals, friction generates heat that can cause material failure.

Bronze-filled PTFE effectively pulls this heat away from the wear surface, preventing overheating and extending the service life of the component.

Improved Electrical Conductivity

While pure PTFE is an excellent electrical insulator, the addition of bronze makes the composite conductive. This is beneficial in applications where the buildup of static electricity must be avoided.

Understanding the Trade-offs

The benefits of bronze fillers come at a cost. Understanding these compromises is essential for proper material selection.

Reduced Chemical Resistance

This is the most critical trade-off. Pure PTFE is nearly chemically inert, but bronze is a metal alloy that is vulnerable to corrosion and attack from various chemicals, particularly acids and strong alkalis.

Therefore, bronze-filled PTFE should not be used in environments where it will be exposed to corrosive media.

Decreased Non-Stick Properties

The presence of bronze particles on the material's surface reduces the classic non-stick quality associated with pure PTFE. This is generally not a concern for its intended mechanical applications but is an important distinction.

Comparison to Other Fillers

Unlike glass-filled PTFE, which is also strong, bronze is less abrasive to mating surfaces like steel shafts. Glass-filled variants can quickly wear down softer metals, making bronze a better choice for preserving the integrity of the entire assembly.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with the primary demands of your project.

- If your primary focus is mechanical performance under high loads: Bronze-filled PTFE is an excellent choice for its combination of compression strength, wear resistance, and low friction in applications like bearings and piston rings.

- If your primary focus is heat dissipation in dynamic systems: The high thermal conductivity of this material makes it ideal for preventing overheating at wear points in high-speed applications.

- If your primary focus is chemical inertness or corrosion resistance: You must choose unfilled PTFE or a more inert filler like glass, as bronze significantly compromises the material's ability to withstand chemical attack.

Ultimately, choosing bronze-filled PTFE is a strategic decision to enhance mechanical durability in applications where extreme chemical resistance is not a requirement.

Summary Table:

| Property | Impact of Bronze Filler |

|---|---|

| Wear Resistance | Significantly Increased |

| Compressive Strength | Dramatically Improved (e.g., ~10.5 MPa at 1% deformation) |

| Thermal Conductivity | Greatly Enhanced (improves heat dissipation) |

| Chemical Resistance | Reduced (vulnerable to corrosive media) |

| Electrical Conductivity | Becomes Conductive (dissipates static charge) |

Need a reliable, self-lubricating component for high-load applications?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom bronze-filled PTFE parts like seals, bushings, and bearings. Our expertise ensures you get the perfect material for your application's demands, from prototypes to high-volume production.

Let us help you enhance your product's performance and durability. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications