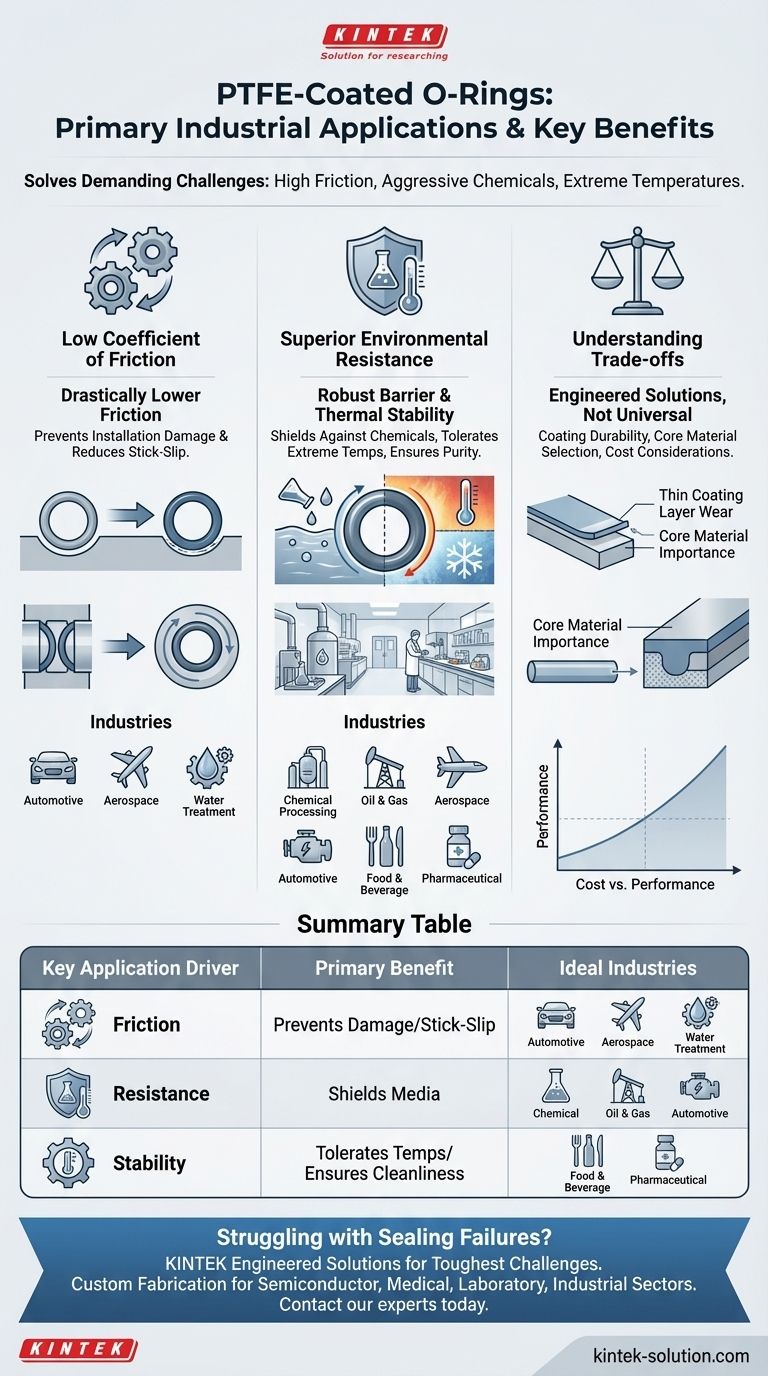

In short, PTFE-coated O-rings are primarily used in demanding industrial applications where standard elastomers fail due to high friction, aggressive chemicals, or extreme temperatures. Key sectors include chemical processing, aerospace, automotive, and food and beverage, where the coating solves critical sealing and installation challenges.

The true value of a PTFE coating is not just a list of industries, but understanding why it's essential. This coating transforms a standard O-ring into a high-performance seal by providing a unique combination of low friction, chemical inertness, and thermal stability that is critical for reliability and safety.

Why the PTFE Coating is a Critical Enhancement

A PTFE-coated O-ring is not a solid PTFE part. It is a standard elastomeric O-ring (like FKM, EPDM, or Silicone) encapsulated in a very thin layer of Polytetrafluoroethylene (PTFE).

This composite design combines the flexibility and sealing force of the elastomer core with the unique surface properties of the PTFE outer layer.

The Primary Functional Benefits

The PTFE coating imparts three game-changing characteristics: a drastically lower coefficient of friction, near-universal chemical resistance, and an expanded temperature range. These properties directly address common points of failure in industrial sealing.

Key Application Driver #1: Low Coefficient of Friction

The most immediate benefit of the PTFE coating is its incredibly slick, non-stick surface. This property is crucial in both static and dynamic applications.

Preventing Installation Damage

In high-volume automated assembly, such as in the automotive industry, O-rings can be easily twisted, pinched, or abraded during installation. The low-friction PTFE surface allows the O-ring to slide smoothly into place without damage, reducing assembly line failures.

Reducing Breakaway Force and Stick-Slip

In dynamic applications like pumps, valves, and hydraulic systems found in aerospace and water treatment plants, "stick-slip" can occur. This is where a standard rubber O-ring adheres to the sealing surface, causing jerky movement and premature wear. The PTFE coating eliminates this issue, ensuring smooth, reliable actuation.

Key Application Driver #2: Superior Environmental Resistance

PTFE is one of the most non-reactive substances known, making it a powerful barrier against harsh industrial environments.

Handling Aggressive Media

The chemical processing and oil & gas industries rely on seals that can withstand a barrage of corrosive chemicals, solvents, and acids. The PTFE coating provides a robust shield, protecting the more vulnerable elastomer core from chemical attack in pumps, reactors, and drilling equipment.

Tolerating Extreme Temperatures

From jet engines in aerospace to transmissions in the automotive sector, O-rings must perform reliably at temperatures that would degrade standard elastomers. The PTFE coating enhances the thermal stability of the seal, preventing it from becoming brittle or overly soft.

Ensuring Purity and Compliance

In the food & beverage and pharmaceutical industries, preventing contamination is paramount. The non-reactive and non-stick nature of PTFE ensures that nothing leaches from the seal into the product and that the seal itself is easy to clean and sterilize.

Understanding the Trade-offs and Limitations

While powerful, PTFE-coated O-rings are not a universal solution. A clear understanding of their limitations is essential for proper application.

Coating Durability

The PTFE coating is very thin. In applications with significant physical abrasion or sharp edges, the coating can be worn away, exposing the underlying elastomer and negating the benefits.

Core Material Still Matters

The coating is a surface enhancement, not a structural one. The choice of the core elastomer is still critical for ensuring proper compression set, pressure rating, and media compatibility should the coating ever be breached.

Cost Considerations

These are specialized, high-performance components. They carry a higher price point than standard uncoated O-rings, and their use should be justified by a clear engineering need for lower friction or enhanced resistance.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to your primary goal.

- If your primary focus is preventing installation damage: A PTFE coating is an excellent choice, especially for high-volume or automated assembly.

- If your primary focus is chemical compatibility: The coating provides a robust barrier, but you must ensure the core elastomer is a safe secondary choice for your media.

- If your primary focus is reducing friction in dynamic applications: PTFE-coated O-rings are a superior solution for eliminating stick-slip and lowering the energy needed for actuation.

- If your primary focus is sealing a simple, static, and non-challenging environment: A standard, uncoated O-ring is often the more practical and cost-effective solution.

Ultimately, choosing a PTFE-coated O-ring is an engineering decision to solve a specific problem that a standard seal cannot.

Summary Table:

| Key Application Driver | Primary Benefit | Ideal Industries |

|---|---|---|

| Low Coefficient of Friction | Prevents installation damage; Reduces stick-slip | Automotive, Aerospace, Water Treatment |

| Superior Chemical Resistance | Shields against aggressive media | Chemical Processing, Oil & Gas |

| Enhanced Thermal Stability & Purity | Tolerates extreme temperatures; Ensures cleanliness | Aerospace, Automotive, Food & Beverage, Pharmaceutical |

Struggling with sealing failures in demanding environments? PTFE-coated O-rings from KINTEK are engineered to solve your toughest challenges—from high friction and chemical attack to extreme temperatures. As specialists in high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors, we offer custom fabrication from prototypes to high-volume orders. Let us provide a sealing solution that ensures reliability and safety for your application. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal