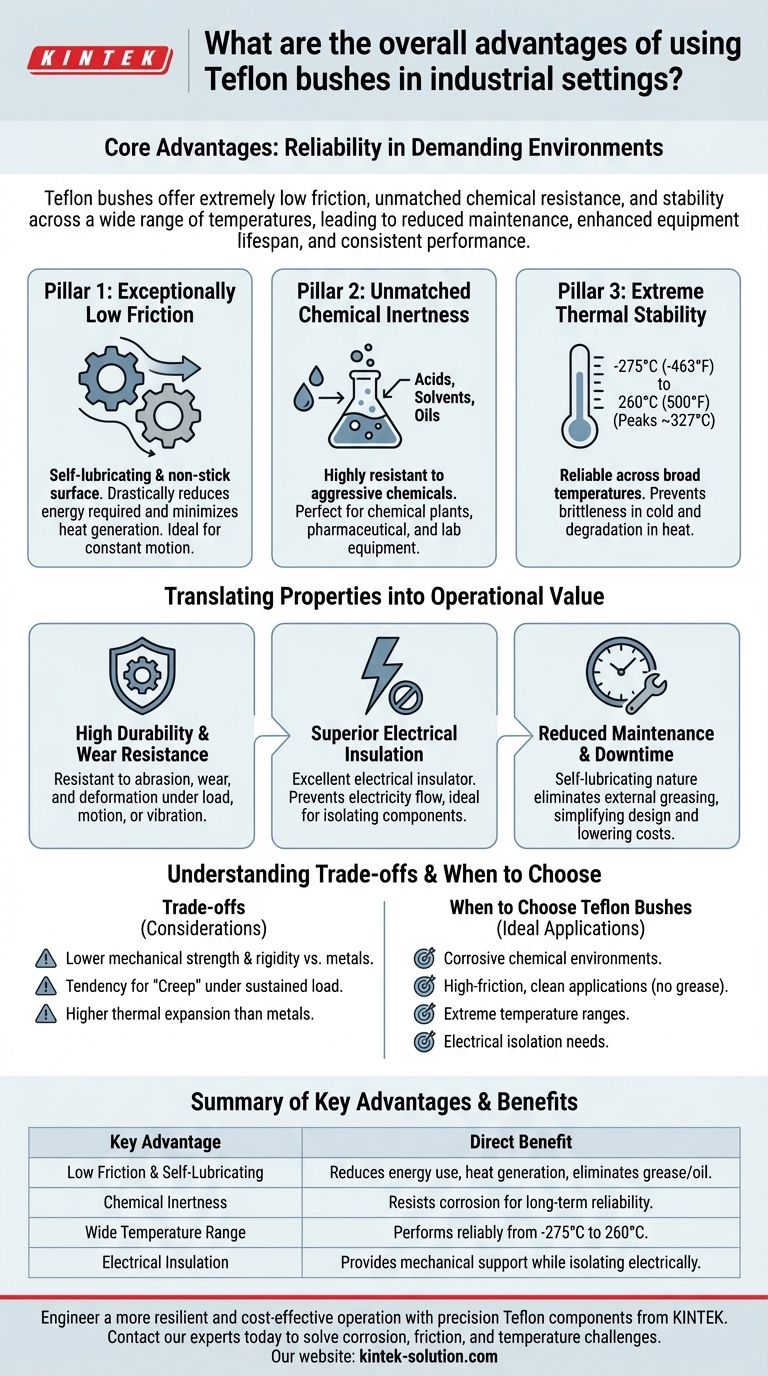

The core advantages of Teflon bushes stem from a unique combination of properties that make them exceptionally reliable in demanding industrial settings. They offer extremely low friction, unmatched chemical resistance, and stability across a wide range of temperatures. This translates directly into reduced maintenance, enhanced equipment lifespan, and consistent performance where other materials would quickly degrade.

The true value of Teflon bushes lies not in a single feature, but in their ability to provide maintenance-free, predictable performance in environments defined by chemical corrosion, extreme temperatures, and high friction. They are a solution for operational resilience.

The Pillars of Teflon's Performance

Teflon (PTFE) bushes derive their advantages from a few fundamental material properties that set them apart from metals, other plastics, and composites. Understanding these pillars is key to deploying them effectively.

Pillar 1: Exceptionally Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. This creates a naturally self-lubricating and non-stick surface.

This property is critical for applications with constant motion, as it drastically reduces the energy required for movement and minimizes heat generation from friction.

Pillar 2: Unmatched Chemical Inertness

Teflon is highly resistant to nearly all industrial chemicals, including aggressive acids, solvents, and oils.

This chemical inertness makes it an ideal choice for machinery in chemical plants, pharmaceutical manufacturing, and laboratory equipment where exposure to corrosive substances is constant.

Pillar 3: Extreme Thermal Stability

Teflon bushes perform reliably across an exceptionally broad temperature range, from cryogenic lows of -275°C (-463°F) up to continuous operating temperatures of 260°C (500°F), with short-term peaks near 327°C (621°F).

This stability ensures the material does not become brittle in the cold or degrade in high-heat applications, a common failure point for many other polymers.

Translating Properties into Operational Value

These core properties deliver tangible, real-world benefits that impact an operation's bottom line through reliability and longevity.

High Durability and Wear Resistance

The combination of low friction and material toughness makes Teflon bushes highly resistant to abrasion, wear, and deformation.

They maintain their integrity even under constant motion, heavy loads, or significant vibration, ensuring long-term performance.

Superior Electrical Insulation

As an excellent electrical insulator, Teflon prevents the flow of electricity. This makes it invaluable for applications where components must be mechanically supported but electrically isolated.

Reduced Maintenance and Downtime

The self-lubricating nature of Teflon eliminates the need for external greasing or oiling, simplifying design and removing a frequent maintenance task.

This reliability, combined with a long service life, leads directly to reduced equipment downtime and lower operational costs.

Understanding the Trade-offs

While its advantages are significant, Teflon is not the universally perfect material for every application. An objective evaluation requires acknowledging its limitations.

Mechanical Strength and Load

Compared to metals like steel or bronze, Teflon has lower compressive strength and rigidity. In applications with extremely high static loads, it can be susceptible to deformation.

Tendency for "Creep"

Under a sustained load, Teflon can exhibit a phenomenon known as "creep" or "cold flow," where the material slowly deforms over time. This must be a consideration in high-load, precision-critical designs.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than metals. This means it expands and contracts more with temperature changes, a factor that engineers must account for when setting clearances and tolerances.

When to Choose Teflon Bushes

Your final decision should be guided by the primary challenge you need to solve in your specific application.

- If your primary focus is operating in corrosive chemical environments: Teflon's chemical inertness is its greatest strength, ensuring it will not degrade.

- If your primary focus is reducing maintenance in a high-friction, clean application: Teflon's self-lubricating nature eliminates the need for external grease or oil.

- If your primary focus is performance across extreme temperature ranges: Teflon maintains its integrity from cryogenic lows to high-heat industrial processes.

- If your primary focus is electrical isolation: Teflon provides excellent insulation while serving its mechanical purpose.

By aligning the unique strengths of Teflon with your specific operational demands, you can engineer a more reliable and cost-effective system.

Summary Table:

| Key Advantage | Direct Benefit |

|---|---|

| Low Friction & Self-Lubricating | Reduces energy use, heat generation, and eliminates need for grease/oil. |

| Chemical Inertness | Resists corrosion from acids, solvents, and oils for long-term reliability. |

| Wide Temperature Range | Performs reliably from -275°C to 260°C (-463°F to 500°F). |

| Electrical Insulation | Provides mechanical support while isolating components electrically. |

Engineer a more resilient and cost-effective operation with precision Teflon components from KINTEK.

Our expertise in custom fabricating PTFE seals, liners, labware, and bushes ensures you get a solution perfectly tailored to your industrial, semiconductor, medical, or laboratory application—from prototypes to high-volume orders.

Contact our experts today to discuss how our components can solve your specific challenges with corrosion, friction, and temperature extremes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions